Rapid brick package folded angle prepressing molding conveying device of brick package filling machine

A technology of pre-compression molding and conveying devices, which is applied in packaging and other directions, can solve the problems of low reliability and complex structure, and achieve the effect of reliable operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described below in conjunction with the drawings.

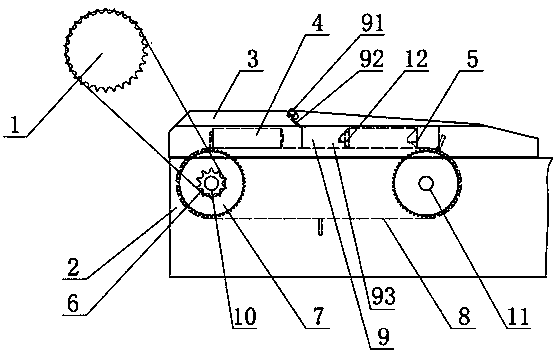

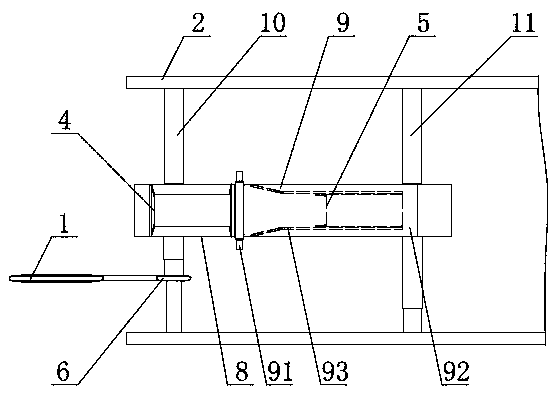

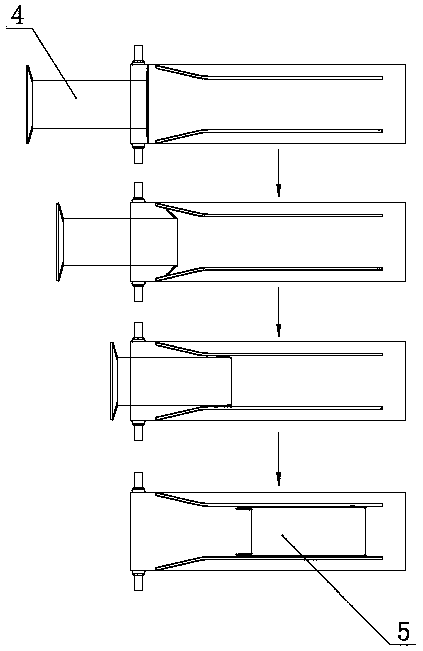

[0015] see figure 1 , figure 2 , The present invention includes a frame, the frame is composed of the conveying wall plate 2, the inner side of the frame is installed in parallel with a conveying driving shaft 10 and a conveying driven shaft 11, and a main driving wheel is installed in parallel on the conveying driving shaft 10 along the axial direction 6 and the conveyor belt wheel 7, the conveyor belt wheel 7 is correspondingly installed on the conveying driven shaft 11, and the conveyor belt 8 is wound on the two conveyor belt wheels 7; the conveyor wall panels 2 on both sides of the frame are equipped with side The distance between the baffles 3 and the baffles 3 on both sides is the width of the conveyor belt 8. A plurality of push blocks 12 are evenly distributed on the conveyor belt 8; the corner pre-compression molding die 9 is placed on the conveyor belt 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com