Novel elevator structure

A new type of elevator technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of the location limitation of the main engine, the decrease of elevator comfort, and the reduction of elevator comfort, so as to reduce the failure rate and eliminate Effects of pressure, energy efficiency improvement and elevator operation comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

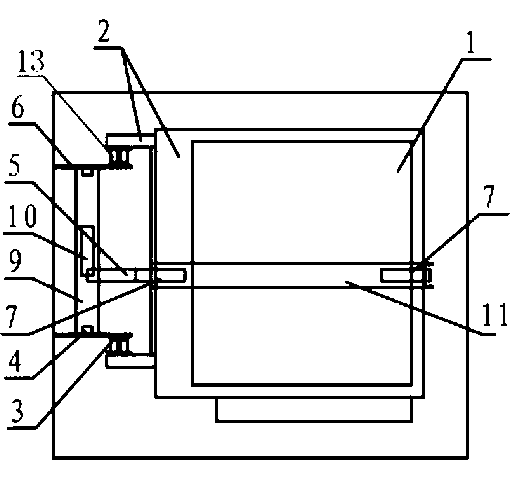

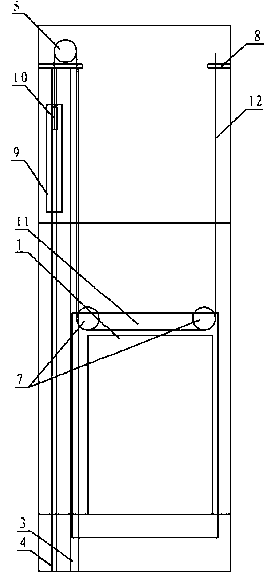

[0027] as attached figure 1 with 3 As shown, a new type of elevator structure includes a car 1 and a car traction load-bearing system. The car traction load-bearing system includes a car frame 2, a guide rail frame 6, a traction machine and a wire rope 12; the traction machine is provided with a traction The guide pulley 5; the car frame 2 is provided with a car wheel 7; the guide rail frame 6 is provided with a car guide rail 3, a counterweight guide rail 4 and a counterweight frame 9; the counterweight frame 9 is provided with a counterweight wheel 10; the car frame 2 is connected with the car guide rail 3 through the guide shoe 13, and it also includes a rope head plate 8; the rope head plate 8 and the traction sheave 5 are respectively located on both sides of the car 1; there are two car wheels 7; There is a base 11 for installing two car wheels 7; one end of a steel wire rope 12 is fixed on the rope head plate 8, and the steel wire rope 12 passes around the two car whee...

Embodiment 2

[0029] as attached figure 1 with 4 As shown, the difference from the first embodiment is that the base 11 is located at the bottom of the car 1 .

Embodiment 3

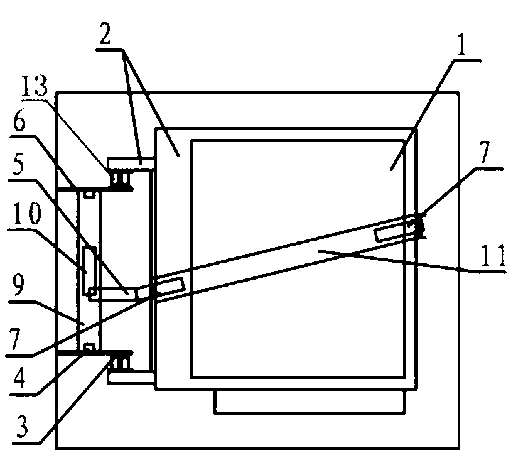

[0031] as attached figure 2 with 3 As shown, the difference from the first embodiment is that the length direction of the base 11 is not perpendicular to the side of the car 1 where the two ends of the base 11 are located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com