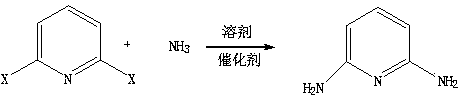

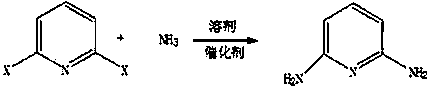

Method for synthesizing 2,6-diamino pyridine

A diaminopyridine and synthesis method technology, applied in the field of 2,6-diaminopyridine synthesis, can solve the problems of low synthesis process yield and many by-products, and achieve good product selectivity, easy operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In the autoclave, add 1mol of 2,6-dichloropyridine, the activated loading capacity is 10% nano-ruthenium carbon catalyst and 800 ml of quinoline, close the autoclave, feed 20mol of liquid ammonia, close After the reactor, the temperature was raised to 350 ° C, and the reaction was stirred for 12 hours. After the reaction, the excess liquid ammonia was drained, 300 ml of water was added, stirred and cooled to 0-5 ° C, 89 g of solids were obtained by filtration, and 99.1% of The 2,6-diaminopyridine product was 81.8 grams, with a melting point of 121.1-122.3°C and a yield of 75%.

Embodiment 2

[0017] Add 1mol of 2,6-bromochloropyridine in the autoclave, the nanometer ruthenium carbon catalyst and the quinoline of 800 milliliters through the activated loading capacity of 10%, close the high pressure reactor, pass into 20mol of liquid ammonia, close After the reactor, the temperature was raised to 350°C and the reaction was stirred for 12 hours. After the reaction, excess liquid ammonia was drained, 300 milliliters of water was added, stirred and cooled to 0-5°C, filtered to obtain 95 grams of solid, and purified with toluene to obtain 99.3% of 2 , 83.5 grams of 6-diaminopyridine product, melting point 121.3-122.5°C, yield 76.6%.

Embodiment 3

[0019] Add 1mol of 2,6-bromochloropyridine in the autoclave, the nanometer ruthenium carbon catalyst and the quinoline of 800 milliliters through the activated loading capacity of 10%, close the autoclave reactor, pass into the liquid ammonia of 20mol, close After the reactor, the temperature was raised to 350 ° C, and the reaction was stirred for 12 hours. After the reaction, the excess liquid ammonia was drained, 300 ml of water was added, stirred and cooled to 0-5 ° C, 102 g of solids were obtained by filtration, and 99.3% of 92.8 g of 2,6-diaminopyridine product, melting point 122.3-122.7°C, yield 85.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com