Feeding system for powdery polyolefin catalyst

A polyolefin catalyst and feeding system technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of instability, blocking feeding, deposition, etc., and achieve the effect of smooth pipeline and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

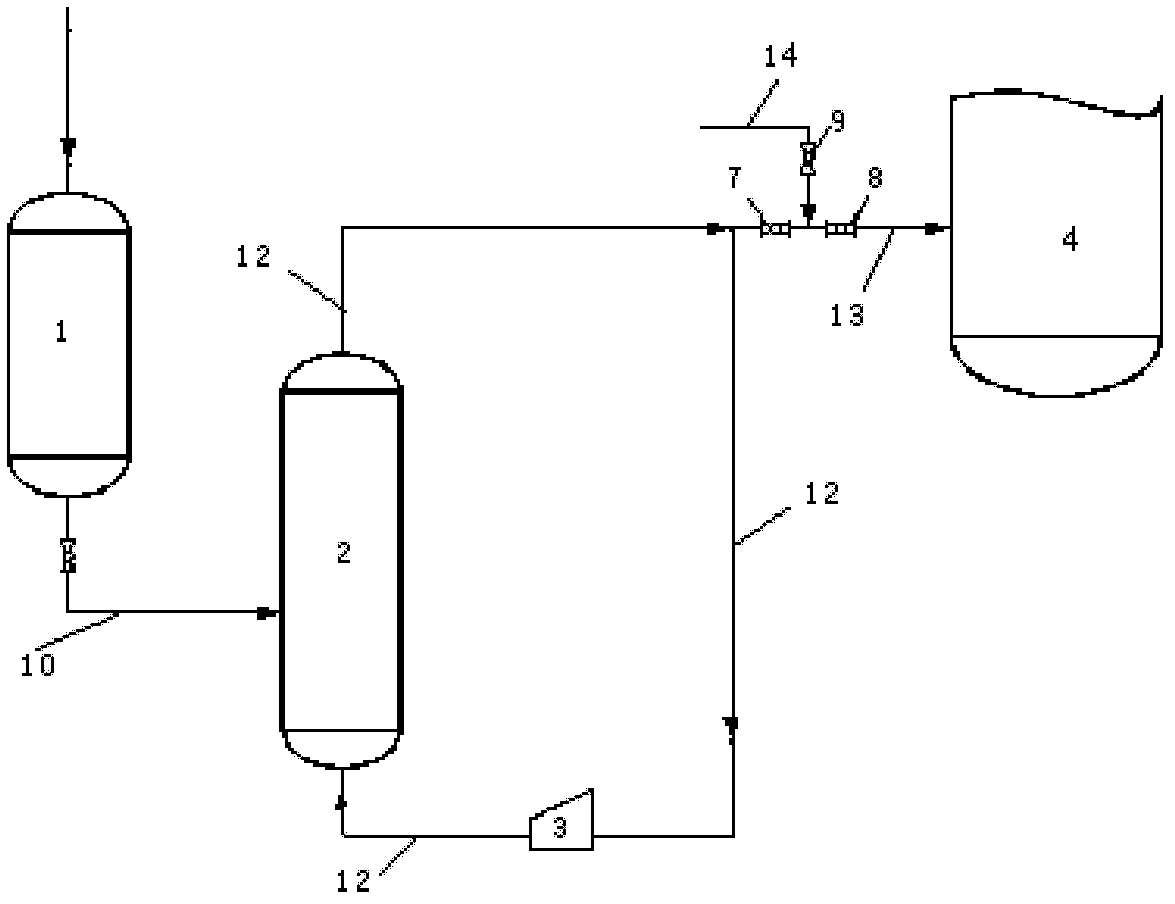

[0029] Such as figure 1 , The catalyst tank is a 2-liter sealed steel pressure vessel containing 200 grams of powdered catalyst. The intermediate tank is a 20-liter sealed steel pressure vessel, and the flow rate of the fan is 150 liters / hour.

[0030] Turn on the fan, the fan and the intermediate tank form a circulation loop, and the gas flows in the circulation loop; then the catalyst particles are intermittently added to the intermediate tank from the bottom of the catalyst tank, and flow together with the gas in the circuit between the fan and the intermediate tank. When the catalyst is fed, the automatic valve 7 is opened, the quantitative tube between the automatic valve 7 and the automatic valve 8 is filled with catalyst and gas, then the automatic valve 7 is closed, the automatic valve 8 and the automatic valve 9 are opened, and the high-pressure gas purge pipeline is connected 14, where the high-pressure gas used is N with a pressure of 1.8MPa 2 (Polymerization reac...

Embodiment 2

[0033] Such as figure 1 , The catalyst tank is a 2-liter sealed steel pressure vessel containing 200 grams of powdered catalyst. The tundish is a 20-liter sealed steel pressure vessel with a gas distributor placed in the lower part. The opening ratio of the gas distributor is 15%. The fan flow rate is 300 l / h.

[0034] Turn on the fan, the fan and the intermediate tank form a circulation loop, and the gas flows in the circulation loop; then the catalyst particles are intermittently added to the intermediate tank from the bottom of the catalyst tank, and flow together with the gas in the circuit between the fan and the intermediate tank. When the catalyst is fed, the automatic valve 7 is opened, the quantitative tube between the automatic valve 7 and the automatic valve 8 is filled with catalyst and gas, then the automatic valve 7 is closed, the automatic valve 8 and the automatic valve 9 are opened, and the high-pressure gas purge pipeline is connected 14, wherein the high-p...

Embodiment 3

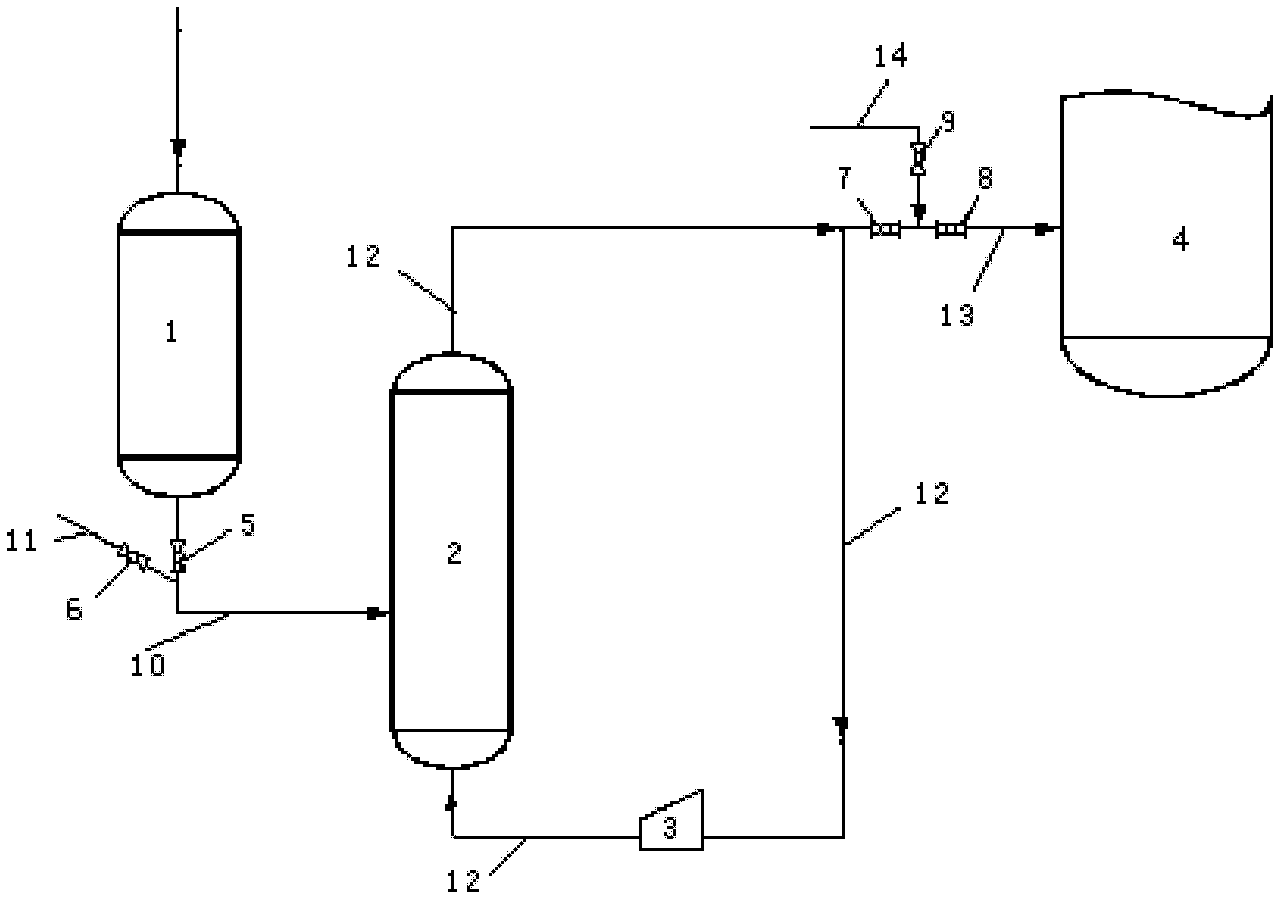

[0037] Such as figure 2 , The catalyst tank is a 2-liter sealed steel pressure vessel containing 200 grams of powdered catalyst. The intermediate tank is a 20-liter sealed steel pressure vessel, and the flow rate of the fan is 20 liters / hour.

[0038] Turn on the fan, the fan and the tundish form a loop, and the gas flows in the loop; when feeding the tundish 2, open the automatic valve 5, add catalyst particles to the tundish 2, close the automatic valve 5, then open the automatic valve 6, and connect Into the gas purge line 11, wherein the gas used is a pressure of N 2 , the pressure is 0.2 ~ 0.3MPa, the pressure of the tundish is generally normal pressure, the catalyst particles in the pipeline are completely blown into the circulation circuit of the tundish 2, and then the automatic valve 6 is closed; the catalyst particles are blown together with the gas in the fan and the tundish Flow in the circuit between, when feeding to the rear system 4, the automatic valve 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com