Preparation process of clean fracturing fluid with remarkably increased viscosity number of system

A technology for clean fracturing fluid and preparation process, applied in the field of clean fracturing fluid preparation technology, can solve problems such as damage to conductivity, decrease in viscosity, loss of effective suspension effect of proppant, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The invention relates to a process for preparing a clean fracturing fluid that significantly increases the viscosity of the system, comprising the following steps:

[0027] (a) First, in the saline solution, add an appropriate amount of surfactant, and stir for a period of time;

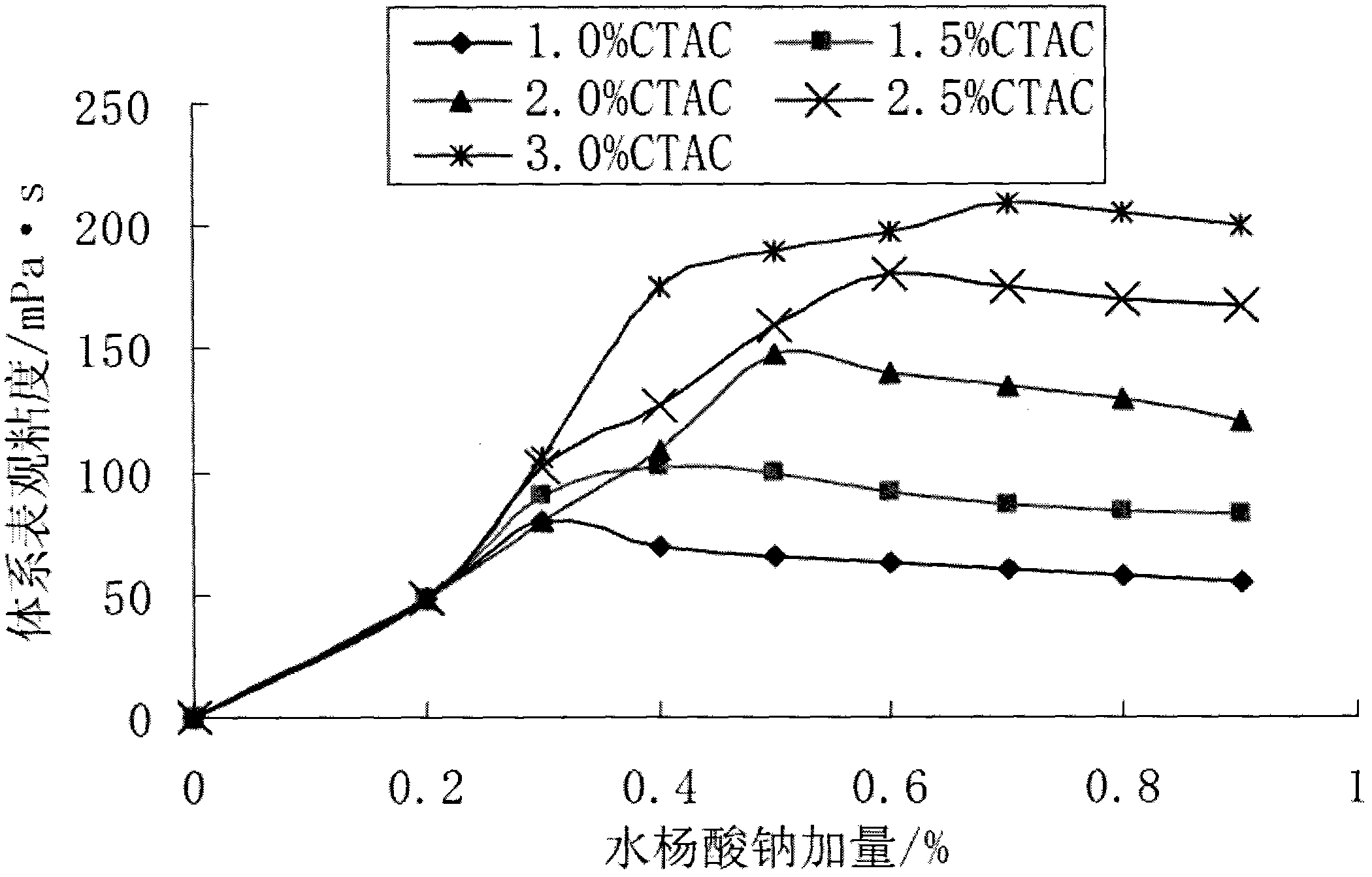

[0028] (b) Then, under the condition of stirring, add a certain amount of sodium salicylate, fully stir to obtain the solution;

[0029] (c) Finally, store it in a constant temperature water bath for a period of time to fully defoam, and then obtain a clean fracturing fluid.

[0030] The above-mentioned saline solution is a sodium chloride solution; the surfactant is cetyltrimethylammonium chloride.

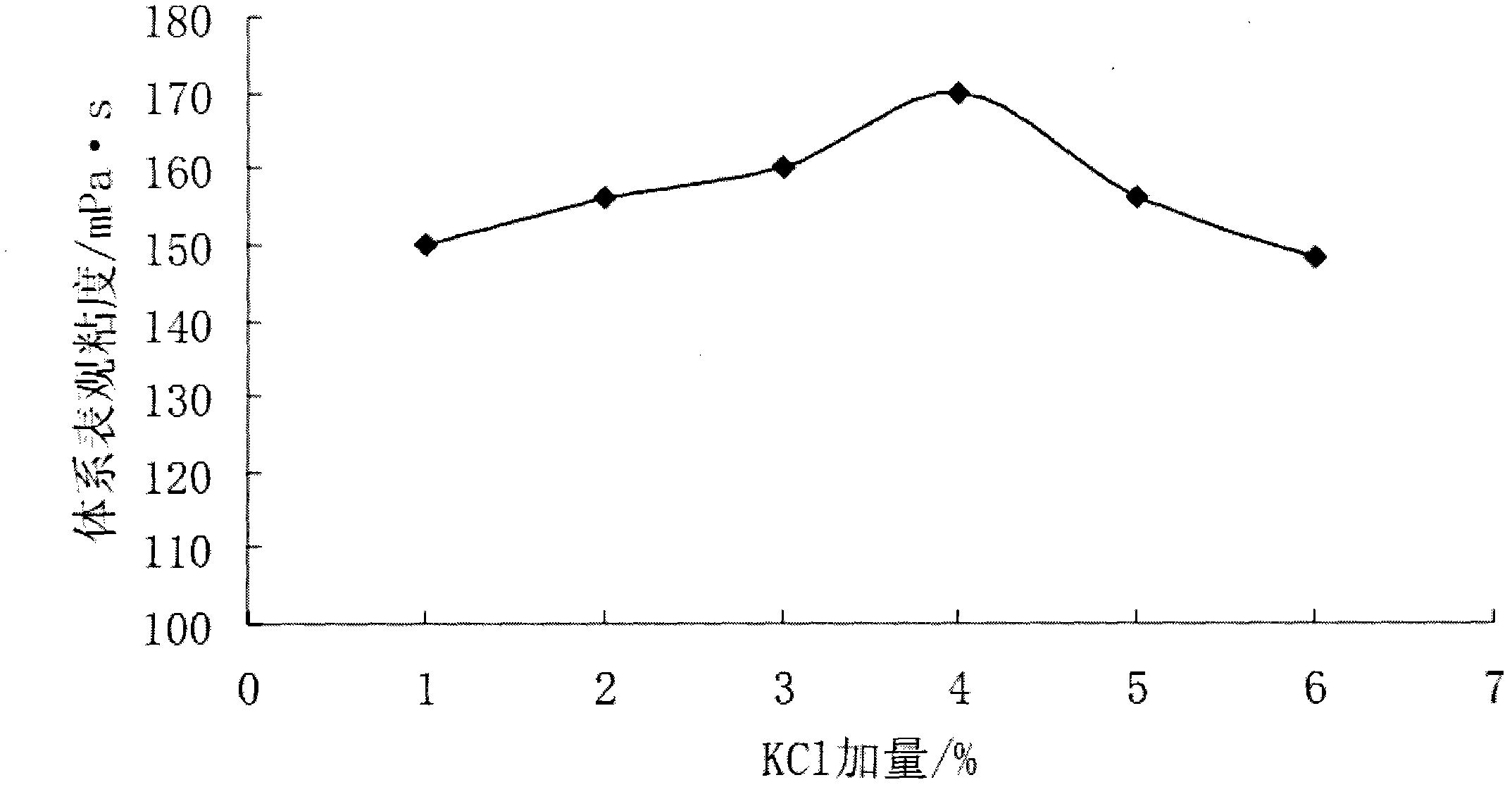

[0031] In order to obtain the best brine dosage, the present invention has done an experiment on the influence of brine dosage on the system concentration of clean fracturing fluid, and the results are as follows figure 1 shown by figure 1 It can be seen that the addition of KCl has little eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com