Device for guiding and condensing raw coal gas of coal pyrolysis furnace

A technology of condensing device and waste gas, which is applied in the field of coke ovens, can solve the problems of difficulty in controlling the pressure in the furnace and the suction force of fans cannot be controlled, and achieves the effect of uniform pressure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation

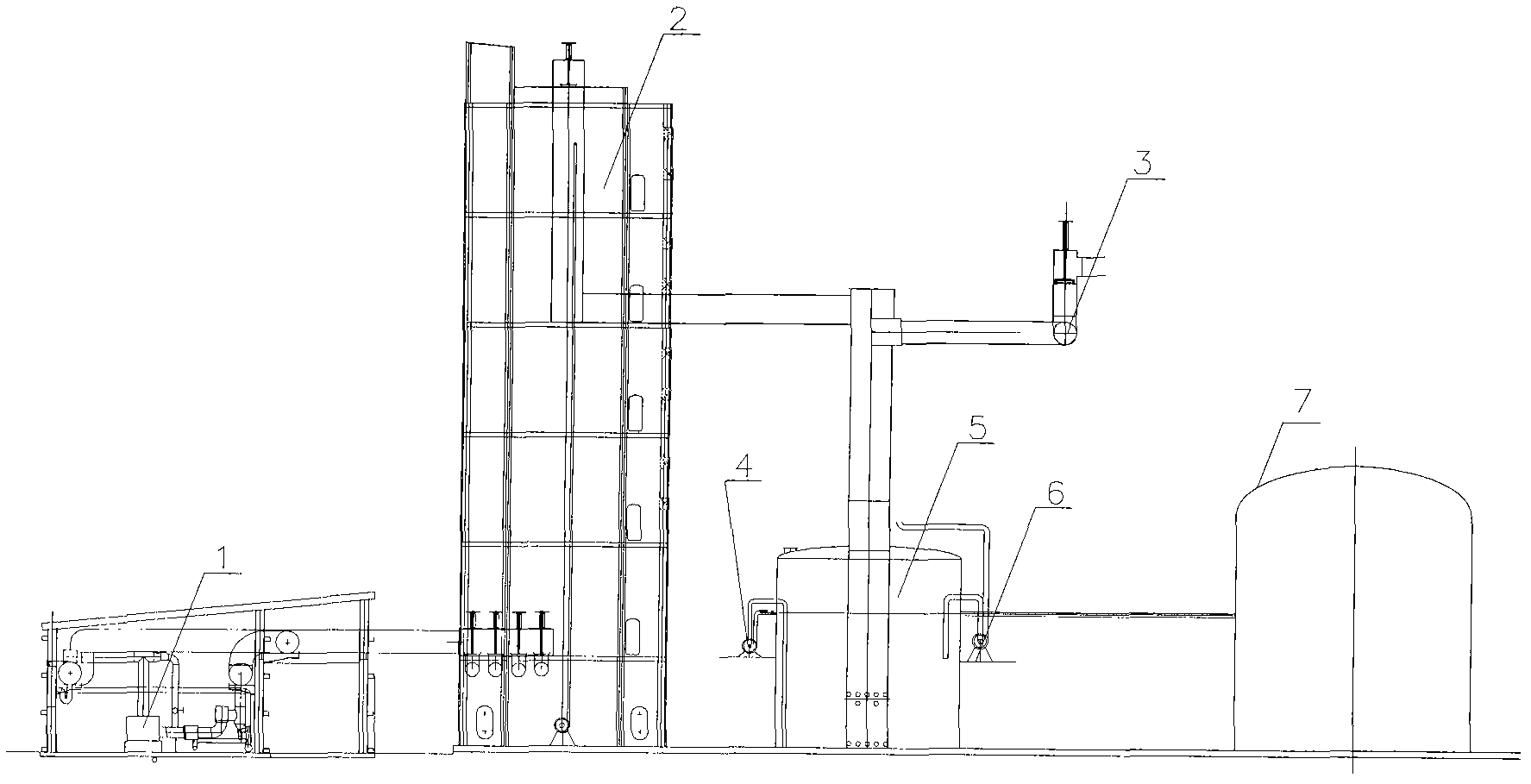

[0009] A raw gas exporting and condensing device of a coal pyrolysis furnace, which includes: a gas blower 1, an air cooler 2, a water seal valve 3, a coal coke pump 4, a gas-liquid separator 5, an ammonia water pump 6 and a tar intermediate tank 7. The gas fan 1 is connected to the air cooler 2, the air cooler 2 is connected to the gas-liquid separator 5, the upper end of the gas-liquid separator 5 is provided with a water seal valve 3, and the left and right sides of the lower end of the gas-liquid separator 5 are respectively provided Coal coke pump 4, ammonia water pump 6 are arranged, and the right side of gas-liquid separator 5 is provided with tar intermediate tank 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com