Yarn breakage detection method and yarn breakage detection device using method

A detection device and detection method technology, applied in textiles and papermaking and other directions, can solve the problems of high cost, difficult maintenance, increased uncertainty, etc., and achieve the effects of low installation position accuracy requirements, less interference, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

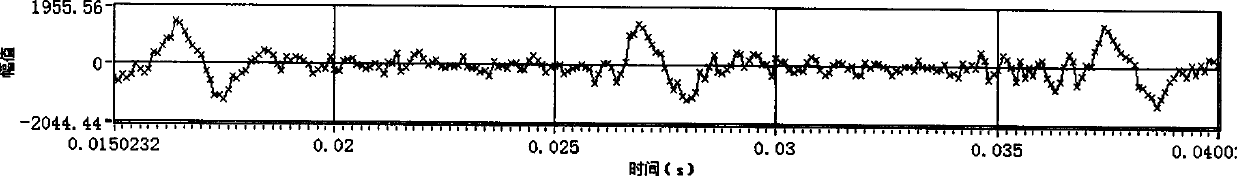

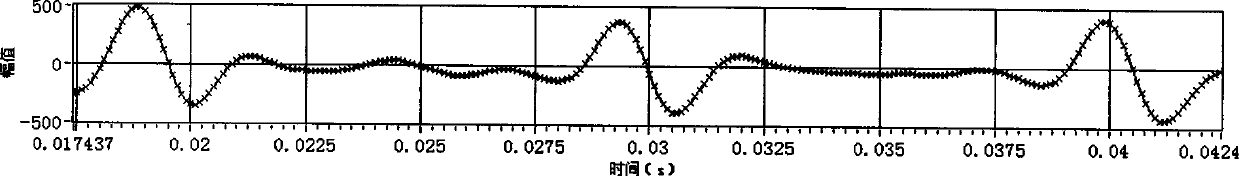

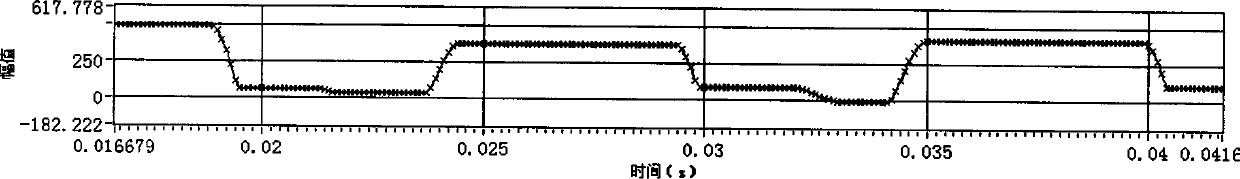

[0017] The yarn breakage detection method of the present invention uses a sound sensor to convert the measured sound into an analog audio signal, digitally samples the audio signal to obtain a digital sound signal, and judges whether the spun yarn breakage occurs according to the characteristics of the digital sound signal obtained by sampling.

[0018] The principle of the spun yarn breakage detection method of the present invention: the traveler and the steel ring have relative motion during spinning, which will generate friction sound. During normal spinning, if the influence of twist shrinkage is ignored, the speed of the traveler is equal to the speed of the spindle minus the front roller The delivery speed is divided by the circumference of the spun yarn. Therefore, the rotation speed of the traveler on the steel ring is slightly lower than the spindle sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com