Power pipe network for clearing deposits under dock

A technology of power pipes and wharves, applied in the field of port engineering, can solve the problems of heavy workload on the water, reduced efficiency, and inability to use port wharves, etc., and achieve the effects of not occupying water space, timely opening, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

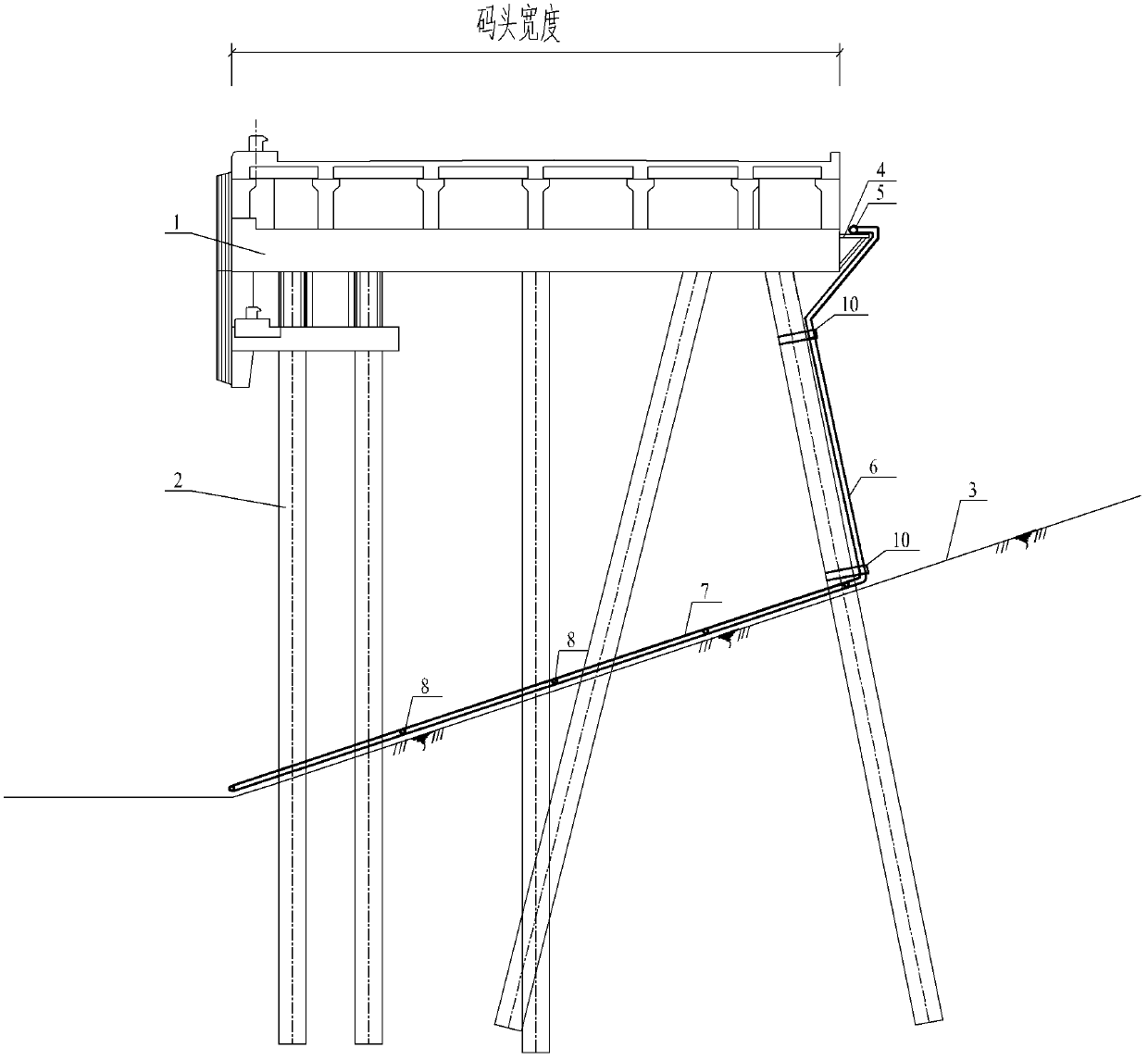

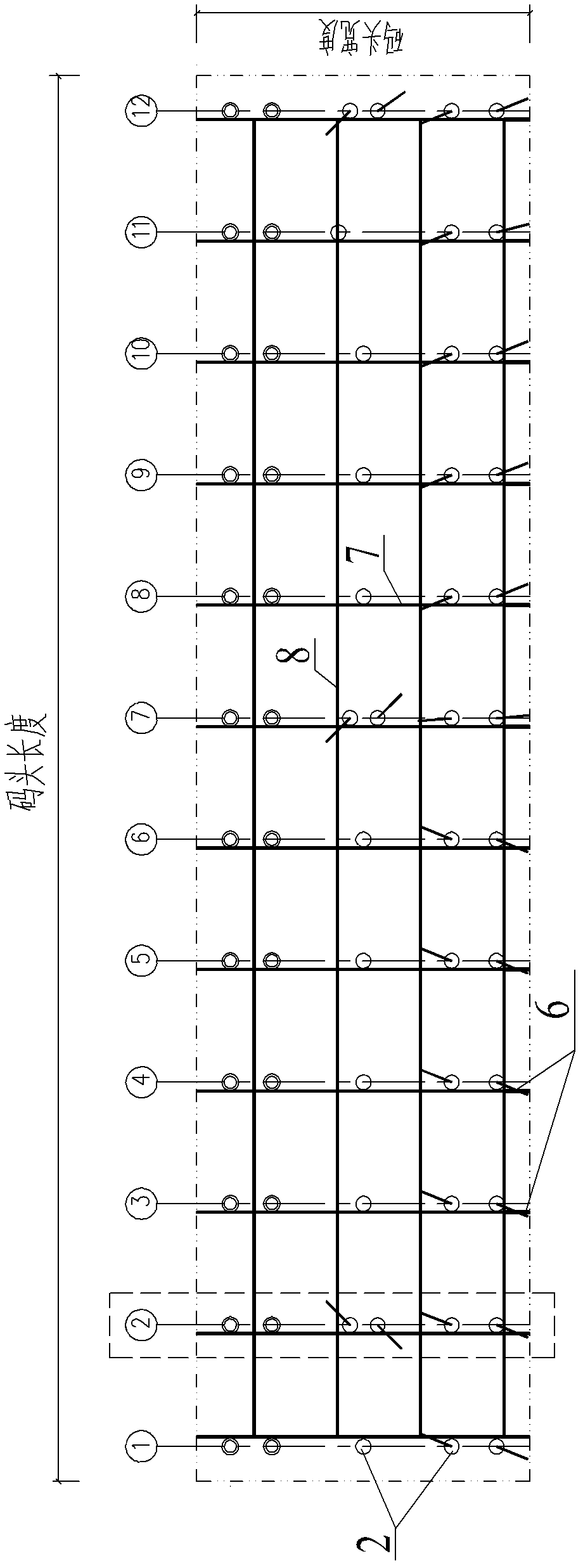

[0033] The embodiment of the power pipeline network that the present invention relates to is as follows:

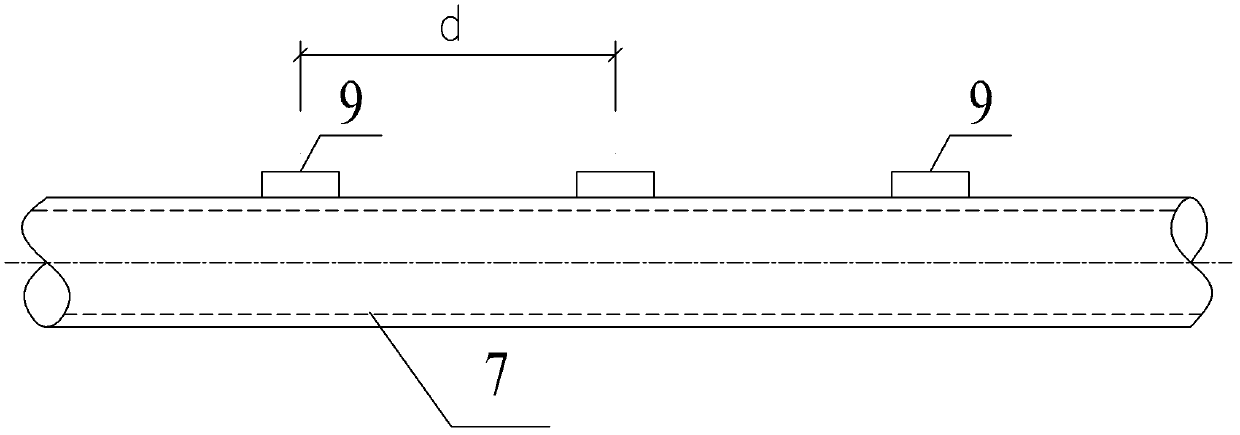

[0034] 1) At the initial stage of wharf construction or after the dredging of the built wharf, the preset or additional power pipe network shall be arranged under the wharf according to the design slope requirements. Install air (or water) pumps and power control devices on the wharf, lay the main pipe along the installation bracket at the back of the wharf, lead out the branch pipes from the main pipe and fix them on the bank slope of the wharf through bent pile foundations, and place them on the bank slope along each bent frame The horizontal pipes are laid horizontally, and the horizontal pipes are fixed by pile foundations, and then the vertical pipes are drawn out from the horizontal pipes and laid at intervals along the longitudinal direction of the wharf, thus forming a dynamic pipe network for gas (water) force flushing mud on the wharf bank slope.

[0035] All pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com