Combined pressure-resistant pipeline inspecting well barrel

A technology for pressure-resistant pipelines and inspection wells, applied in water conservancy projects, waterway systems, artificial islands, etc., can solve problems such as high production and maintenance costs, difficult transportation and installation, poor manufacturing process, etc., and achieve waterproof and anti-corrosion performance guarantee , Die structure simplification, product pass rate improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

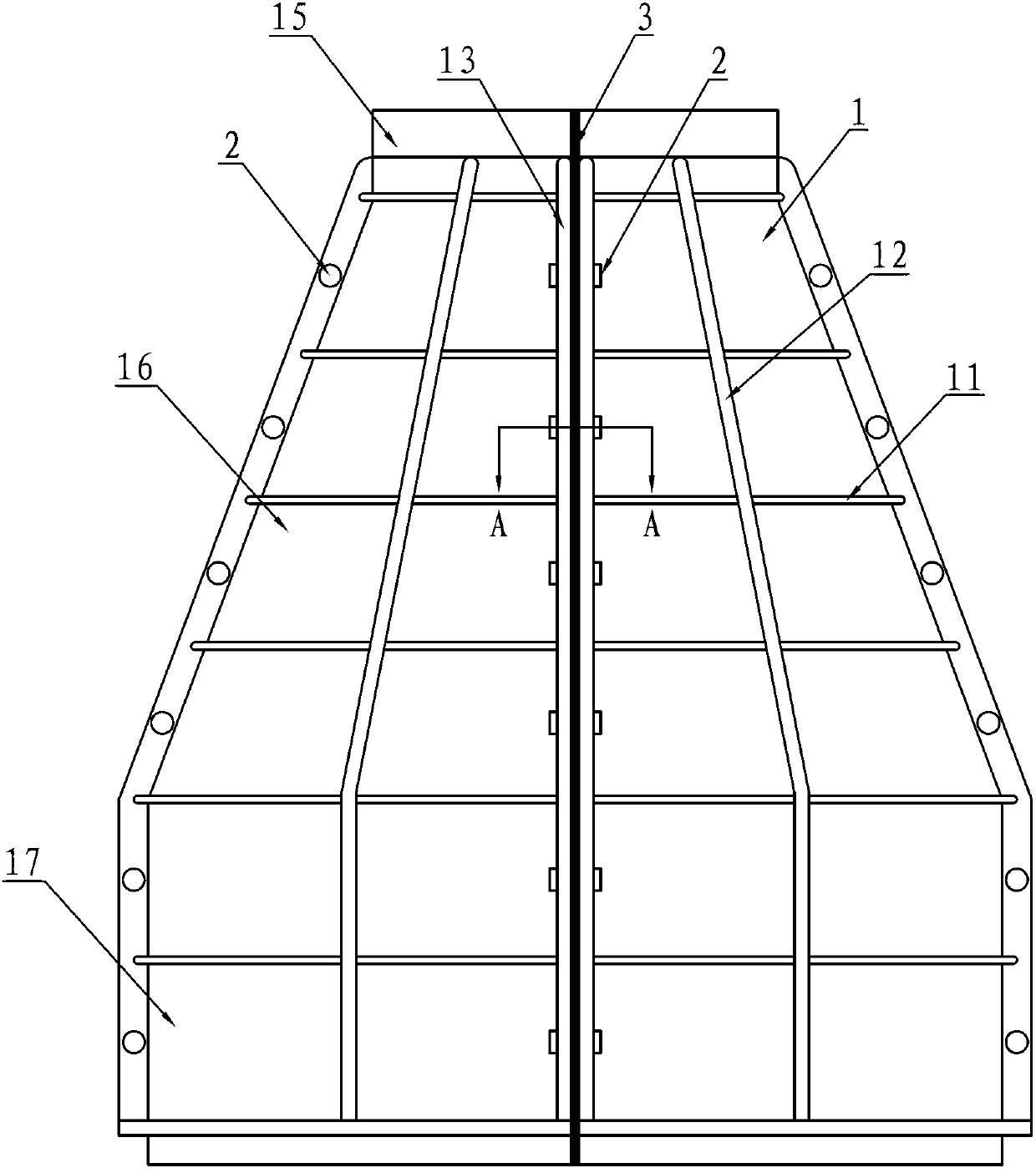

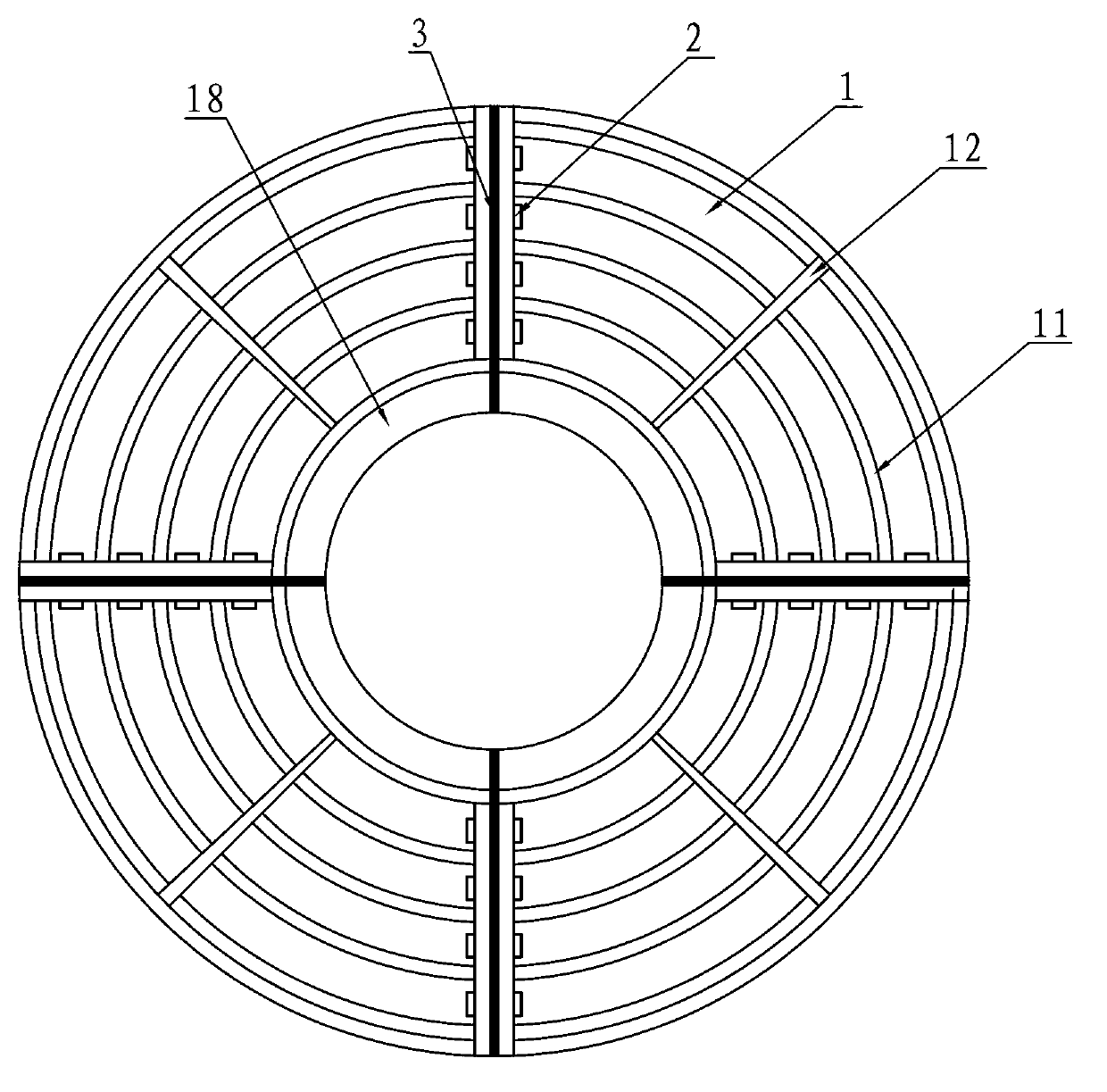

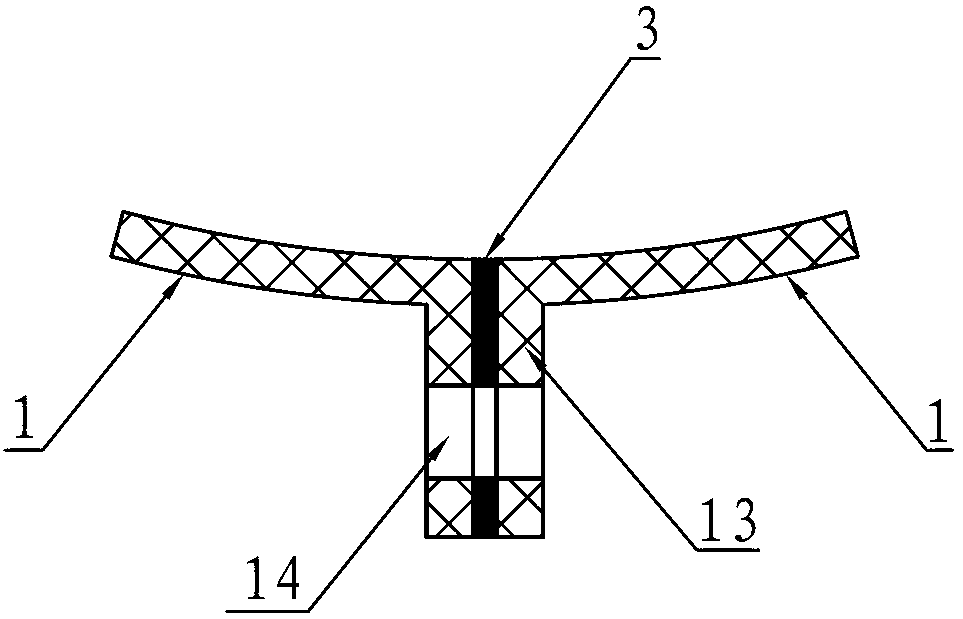

[0017] A combined pressure pipeline inspection well barrel, such as Figure 1~Figure 3 As shown, it is composed of four combined sheets 1, connectors 2 and sealing layer 3, the shape of the horizontal section of the combined sheet 1 is arc-shaped, and the fan angle of the arc is 90 °, outside the combined sheet 1 The arc surface is provided with transverse reinforcing ribs 11 and longitudinal reinforcing ribs 12, the transverse reinforcing ribs 11 are distributed at equal intervals along the height direction, the longitudinal reinforcing ribs 12 are distributed at equal angles along the circumferential direction, and the transverse reinforcing ribs 11 and the longitudinal reinforcing ribs 12 intersect each other, The left and right sides of the combined sheet 1 are provided with connecting edges 13, and connecting holes 14 are provided on the connecting edges 13. The longitudinal section of the combined sheet 1 is composed of a wellhead section 15, a well cone section 16 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com