High-viscosity high-weather-resistance emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and weather resistance, applied in building components, building insulation materials, buildings, etc., can solve the problems of unsatisfactory dispersion effect of natural montmorillonite, and achieve the effect of improving anti-aging performance, excellent barrier performance and prolonging diffusion path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

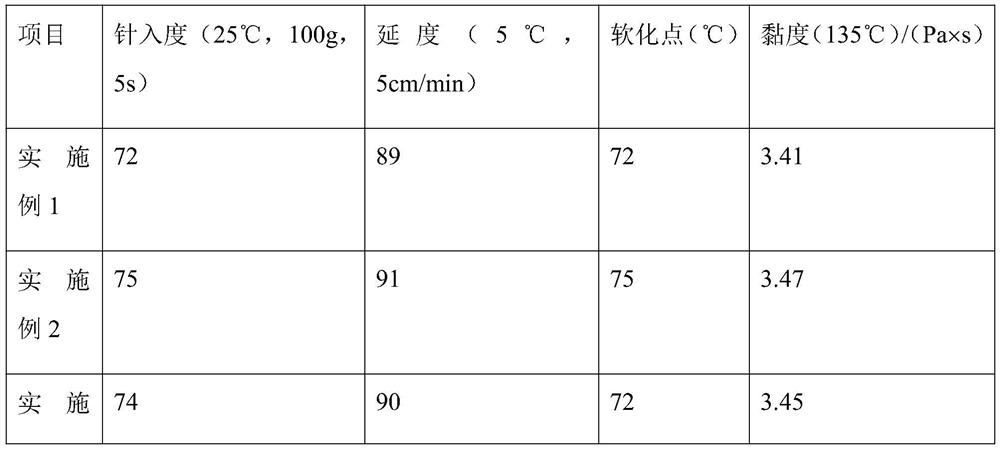

Examples

Embodiment 1

[0027] A preparation method of high-viscosity and high-weather-resistant emulsified asphalt, comprising the following steps:

[0028] (1) Take 20 mg of ferric oxide particles, 60 mL of absolute ethanol and 8 mL of deionized water, and after mixing, ultrasonically disperse for 20 minutes, add 4 mL of ammonia water, continue to ultrasonically disperse for 30 minutes, and then add 0.4 mL of tetrabutyl titanate, and stir for 1 h. Magnetic separation and vacuum drying at 50°C to obtain magnetic nanowires. The magnetic nanowires were prepared under the condition of a horizontal magnetic field, and the magnetic field strength was 50 mT.

[0029] Take montmorillonite and deionized water, ultrasonically disperse for 25min to obtain 10g / L montmorillonite suspension;

[0030] Take magnetic nanowires and absolute ethanol, ultrasonically disperse them for 20 min to obtain a dispersion of 1 g / L; take dopamine and Tris buffer, mix and dissolve to obtain a mixed solution, the concentration o...

Embodiment 2

[0036] A preparation method of high-viscosity and high-weather-resistant emulsified asphalt, comprising the following steps:

[0037] (1) Take 20 mg of ferric oxide particles, 60 mL of absolute ethanol and 8 mL of deionized water, and after mixing, ultrasonically disperse for 25 minutes, add 4 mL of ammonia water, continue ultrasonic dispersion for 35 minutes, then add 0.4 mL of tetrabutyl titanate, and stir for 1.2 h. , magnetic separation, and vacuum drying at 55 °C to obtain magnetic nanowires. The magnetic nanowires were prepared under the condition of a horizontal magnetic field, and the magnetic field strength was 50 mT.

[0038] Take montmorillonite and deionized water, ultrasonically disperse for 30min to obtain 10g / L montmorillonite suspension;

[0039]Take the magnetic nanowires and absolute ethanol, ultrasonically disperse them for 25 min to obtain a dispersion of 1 g / L; take dopamine and Tris buffer, mix and dissolve to obtain a mixed solution, the concentration o...

Embodiment 3

[0045] A preparation method of high-viscosity and high-weather-resistant emulsified asphalt, comprising the following steps:

[0046] (1) Take 20 mg of ferric oxide particles, 60 mL of absolute ethanol and 8 mL of deionized water, and after mixing, ultrasonically disperse for 30 minutes, add 4 mL of ammonia water, continue to ultrasonically disperse for 40 minutes, and then add 0.4 mL of tetrabutyl titanate, and stir for 1.5 hours. , magnetic separation, and vacuum drying at 60 °C to obtain magnetic nanowires. The magnetic nanowires were prepared under the condition of a horizontal magnetic field, and the magnetic field strength was 50 mT.

[0047] Take montmorillonite and deionized water, ultrasonically disperse for 35min to obtain 10g / L montmorillonite suspension;

[0048] Take the magnetic nanowires and absolute ethanol, ultrasonically disperse them for 30 min to obtain a dispersion of 1 g / L; take dopamine and Tris buffer, mix and dissolve to obtain a mixed solution, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com