Printing process for forming multi-layer three-dimensional pattern through prism refraction

A prismatic refraction and pattern technology, which is applied in the printing process, printing and printing of special varieties of printed matter, can solve the problems of poor anti-aging performance, yellowing and shedding, etc., to ensure anti-aging performance and strengthen anti-aging performance. , The effect of not easy to yellow and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a printing process for forming a multi-layer three-dimensional pattern by prism refraction. The specific printing steps are as follows:

[0033] Step 1: Put the base material of the base material into a hot pressing mold to produce a transparent plastic film with prism bumps on the front;

[0034] Step 2: According to the pattern to be printed, use a CTP direct plate-making machine for plate making;

[0035] Step 3: Put the sample plate obtained in step 2 into the UV printer, and then use the UV printer to print the back of the transparent plastic film with prism bumps on the front made in step 1. The UV printer uses water-based The UV ink is used for three-layer composite printing to obtain a plastic film with multi-layer three-dimensional patterns formed by prism refraction.

[0036] In step one, the prism bumps are hemispherical bumps, the height of the prism bumps is smaller than the spherical radius of the prism bumps, and the distance between...

Embodiment 2

[0049] Different from Example 1, the water-based UV ink includes: 56.50% water-based UV resin, 9.20% photoinitiator, 4.80% anti-aging agent A, 4.90% anti-aging agent B, 24.60% by weight percentage. % active diluent; the anti-aging agent A includes by weight percentage: 19.60% zinc acetate, 15.80% cellulose nanofibers, 64.60% polyvinylpyrrolidone; the anti-aging agent B includes by weight percentage : 33.50% silver nitrate, 46.80% resveratrol, 5.80% sodium hydroxide, 13.90% glass fiber.

Embodiment 3

[0051] All different from Examples 1-2, the water-based UV ink includes: 55.90% water-based UV resin, 8.85% photoinitiator, 4.20% anti-aging agent A, 4.50% anti-aging agent B, 26.55% reactive diluent; the antiaging agent A includes: 19.00% zinc acetate, 15.50% cellulose nanofibers, 65.50% polyvinylpyrrolidone; the antiaging agent B is calculated by weight The percentage calculation includes: 32.90% silver nitrate, 46.05% resveratrol, 5.20% sodium hydroxide, 15.85% glass fiber.

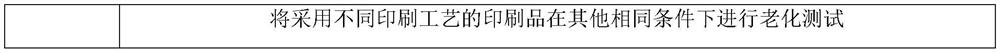

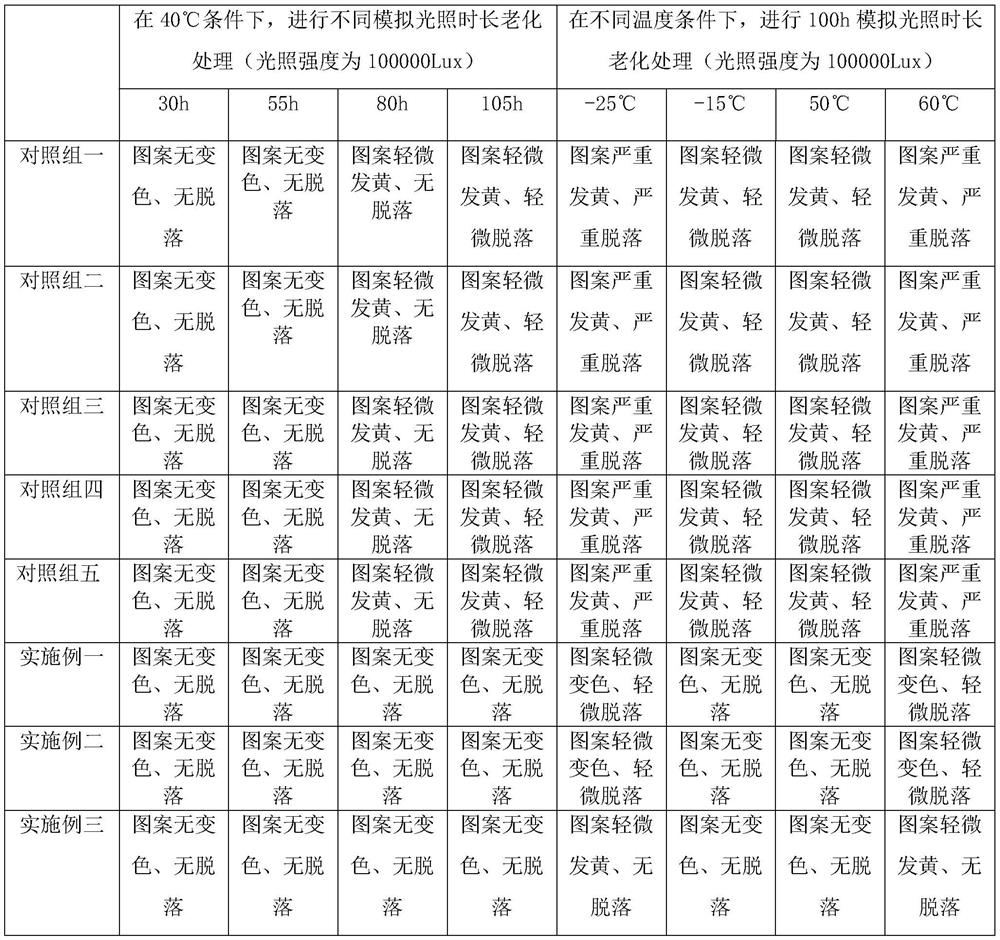

[0052] Get respectively the printing process in the above-mentioned embodiment 1-3 and the printing process of the matching group one, the printing process of the matching group two, the printing process of the matching group three, the printing process of the matching group four and the printing process of the matching group five, the matching group The printing process of one does not have zinc acetate in water-based UV ink compared with embodiment; The printing process of control group two does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com