Multi-stage hydraulic expansion tail pipe suspension system with reducing expansion cone for horizontal well for thermal recovery of heavy oil

A heavy oil thermal recovery and liner suspension technology, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of scrapped wellbore, damage to the inner wall of the expansion pipe, intensified formation instability, etc., to solve the problem of steam channeling The effect of burying with sand, reducing the friction of running in, and keeping the wellbore clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

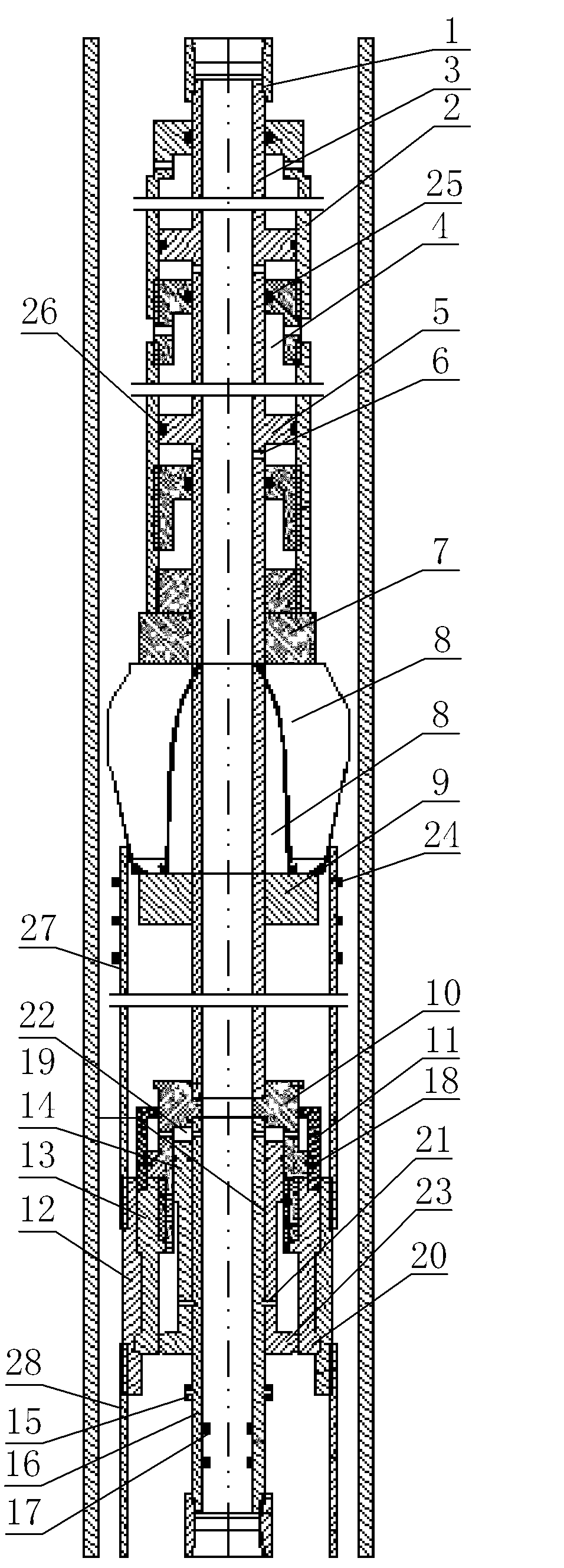

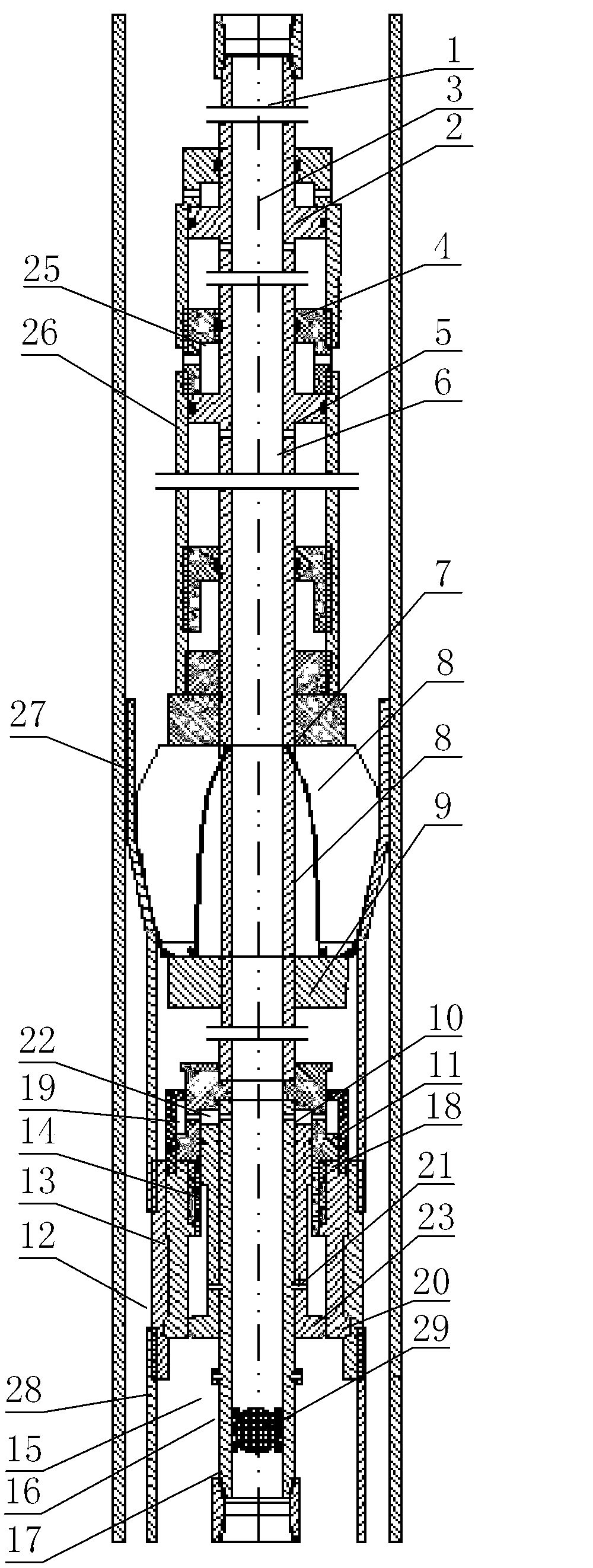

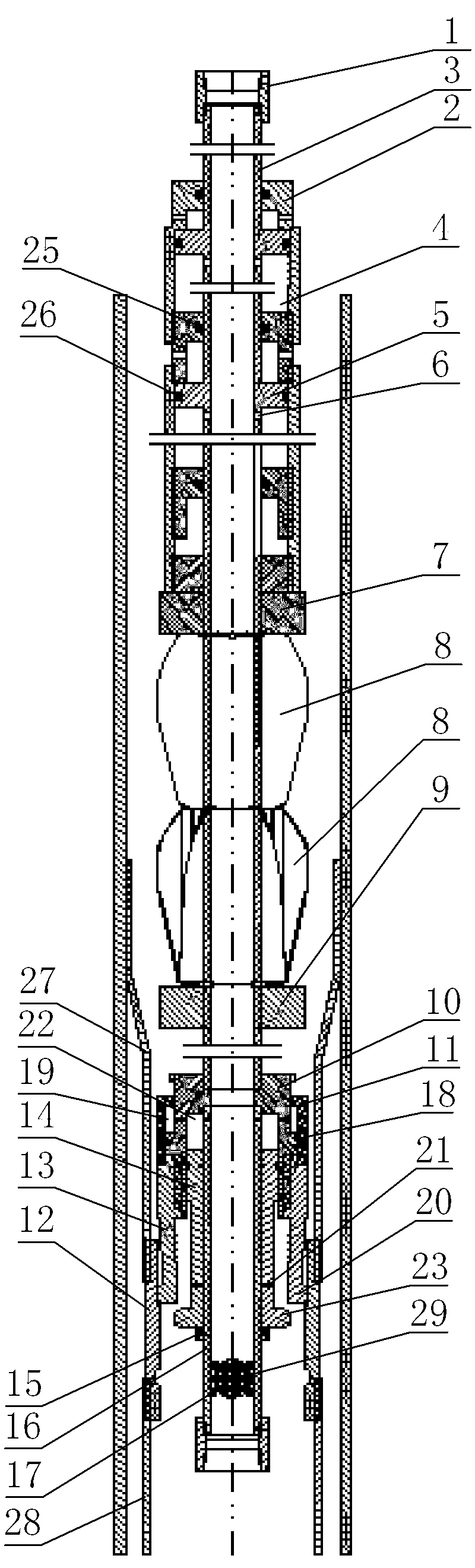

[0023] Such as figure 1 As shown, the multi-stage hydraulic expansion liner suspension system for heavy oil thermal recovery horizontal wells with variable-diameter expansion cones includes an upper joint 1, a multi-stage hydraulic cylinder power system, variable-diameter expansion cones, expansion tube hangers 27 and hydraulic- Mechanical double-acting hands-off system, the upper joint 1 is provided with an internal thread.

[0024] The multi-stage hydraulic expansion liner suspension system includes a multi-stage hydraulic cylinder liner 2 and a hollow piston rod 3, the inner thread at the lower end of the upper joint 1 is connected with the upper end of the hollow piston rod 3, and the multi-stage hydraulic cylinder liner 2 is provided with a A plurality of mutually independent hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com