Drainage system for tunnel in severe cold region

A drainage system and tunnel technology, applied in drainage, safety devices, mining equipment, etc., can solve the problems of failure to handle the connection relationship of blind pipes in horizontal drainage, construction cost increase, cost waste, etc., to save material and labor costs, save Material costs and the effect of reducing construction man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

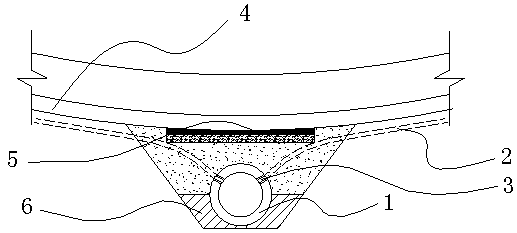

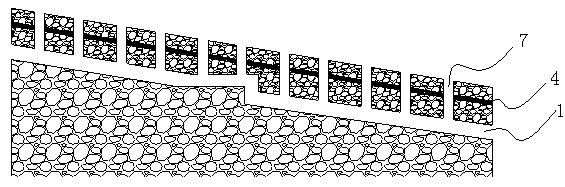

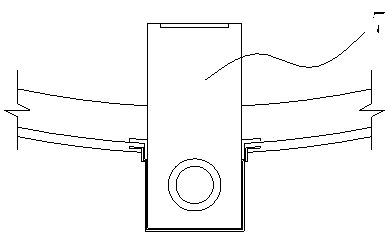

[0022] according to figure 1 and figure 2 As shown, a drainage system for a tunnel in a severe cold region includes an upward supply primary branch layer 4, a central water pipe 1 and a horizontal water pipe 2.

[0023] Among them, a central water pipe groove extending along the center line of the tunnel is also excavated below the primary support layer 4 for the upper supply. After the groove is excavated in place, a C20 concrete leveling layer 6 is applied at the bottom of the groove. The leveling layer 6 is equipped with a central water pipe 1 that communicates with the lining drainage blind pipe through a horizontal water pipe 2 .

[0024] When the length of the tunnel is less than or equal to four thousand meters, the central water pipe 1 is all deeply buried, and the drainage surface of the deeply buried central water pipe 1 is below the local freezing line, and the center of the end of the deeply buried central water pipe 1 is 3.7 meters away from the ground surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com