Mechanical vibration signal vibration-damping and filtering device for high-speed gear box

A mechanical vibration, high-speed gear technology, applied in mechanical equipment, vibration suppression adjustment, spring/shock absorber, etc., can solve the problems of insignificant vibration damping effect, influence experimental effect, and lack of independence, and achieve compensation for axial Displacement, flexibility and independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

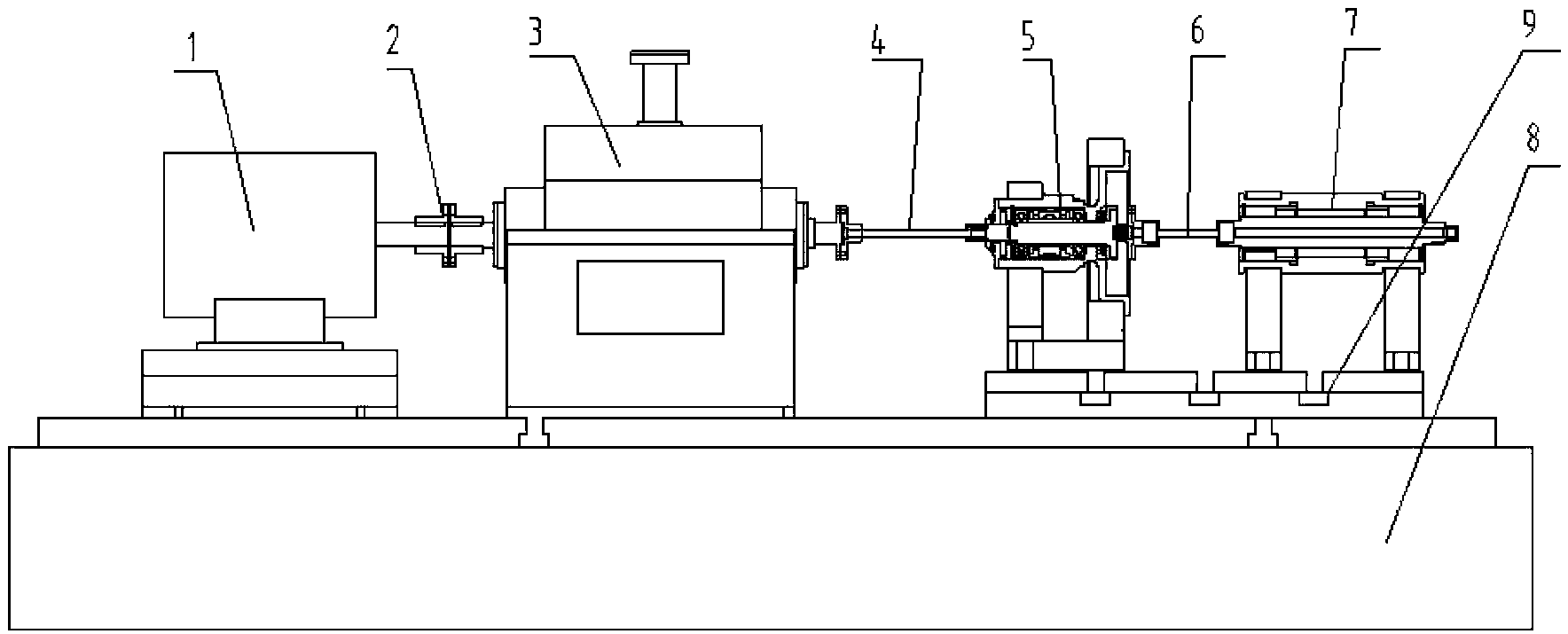

[0026] see figure 1 , a mechanical vibration signal damping and filtering device for a high-speed gearbox, including a motor 1, the output shaft of the motor 1 is connected to the input of a gearbox 3 through a diaphragm coupling 2, and the output of the gearbox 3 is connected through a spline coupling One end of the transition rotor 4 is connected to the transition rotor part 5, and the other end of the transition rotor part 5 is connected to the test piece 7 through the thin-walled sleeve coupling 6, and the test piece 7 is installed on the overall test bench 8 through the installation platform 9.

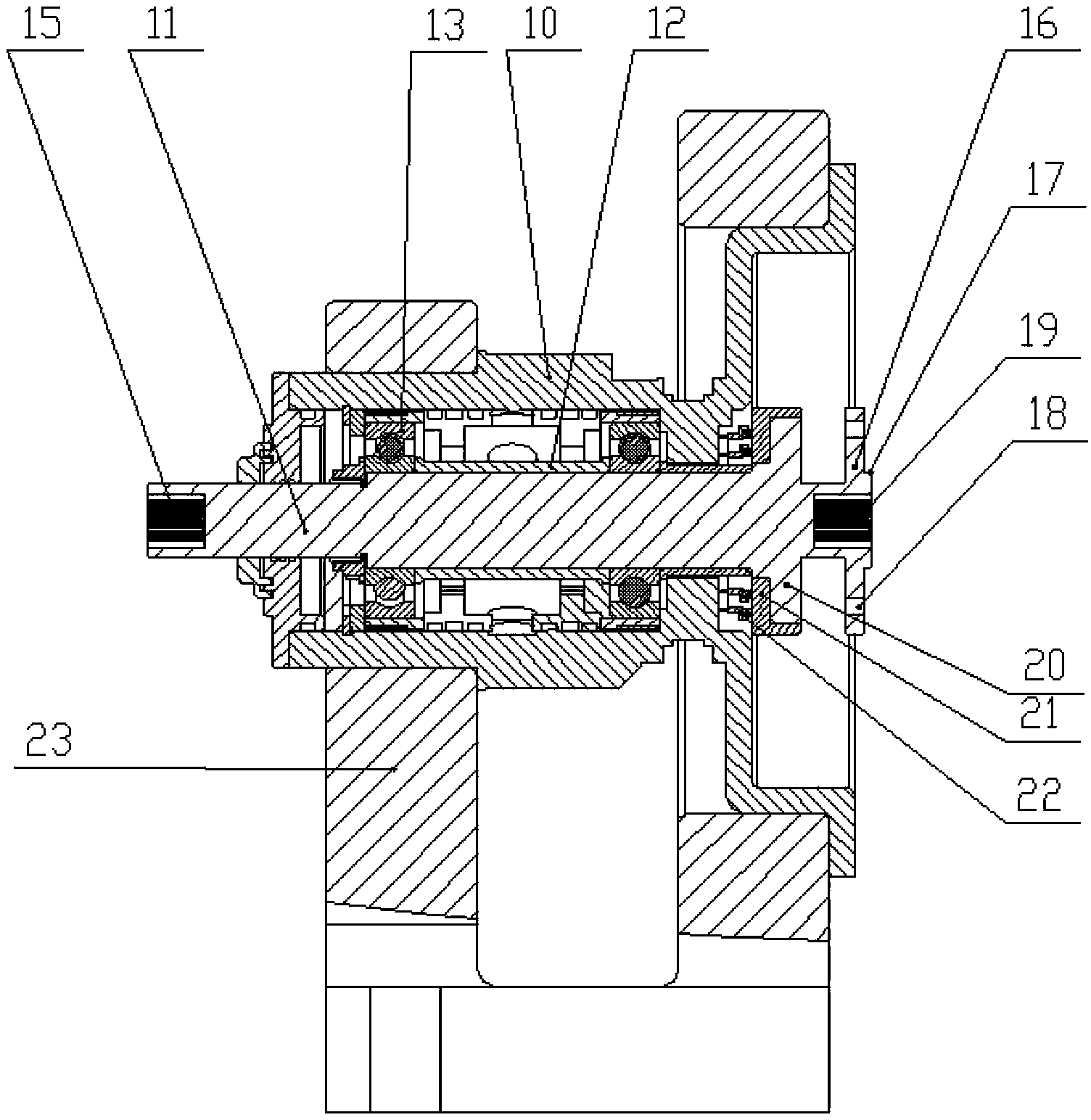

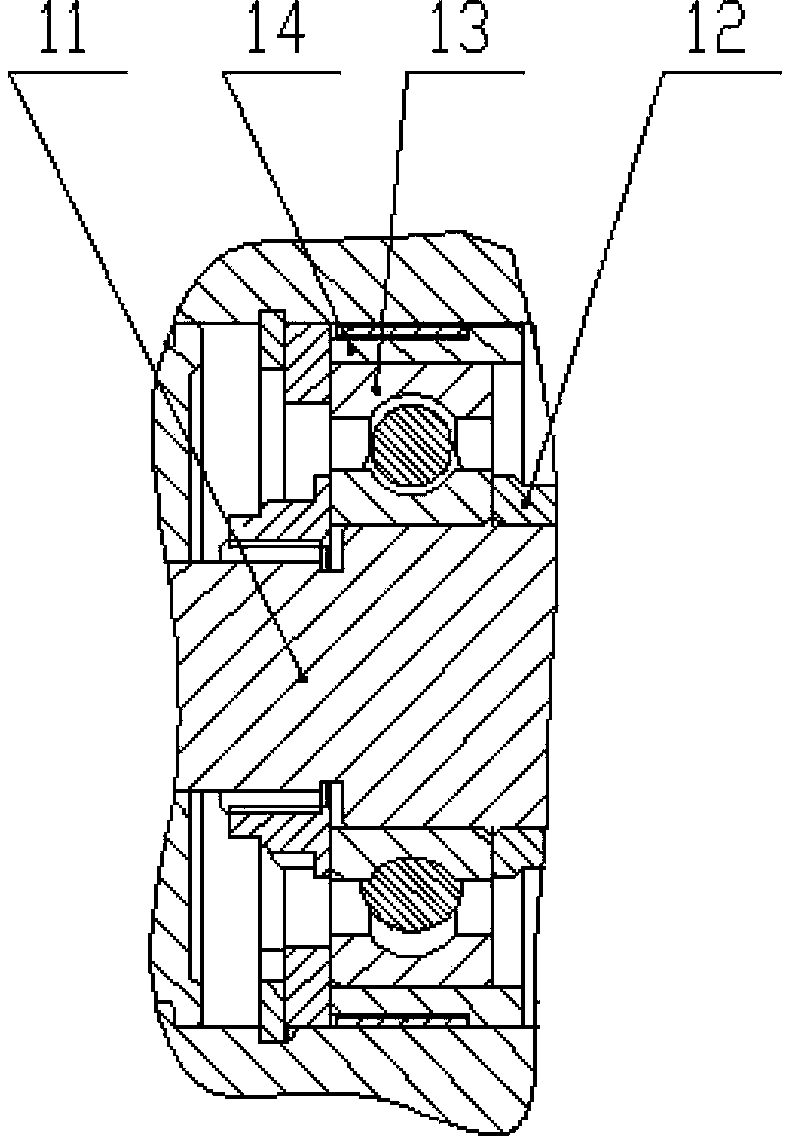

[0027] refer to figure 2 , the transition rotor part 5 includes a casing 10, a shaft 11, a sleeve 12 installed in the middle of the shaft 11, and support bearings 13 installed on both sides of the sleeve 12, and the support bearings 13 are positioned and axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com