A method for improving the carrying capacity of rack and pinion lifting device of self-elevating platform

A self-elevating platform, rack and pinion technology, applied in the direction of portable lifting devices, hoisting devices, transmission devices, etc., can solve the problems of reducing the size of contact surface stress, fatigue damage of rack and pinion, stress concentration, etc., to achieve the maximum Effect of Contact Stress Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

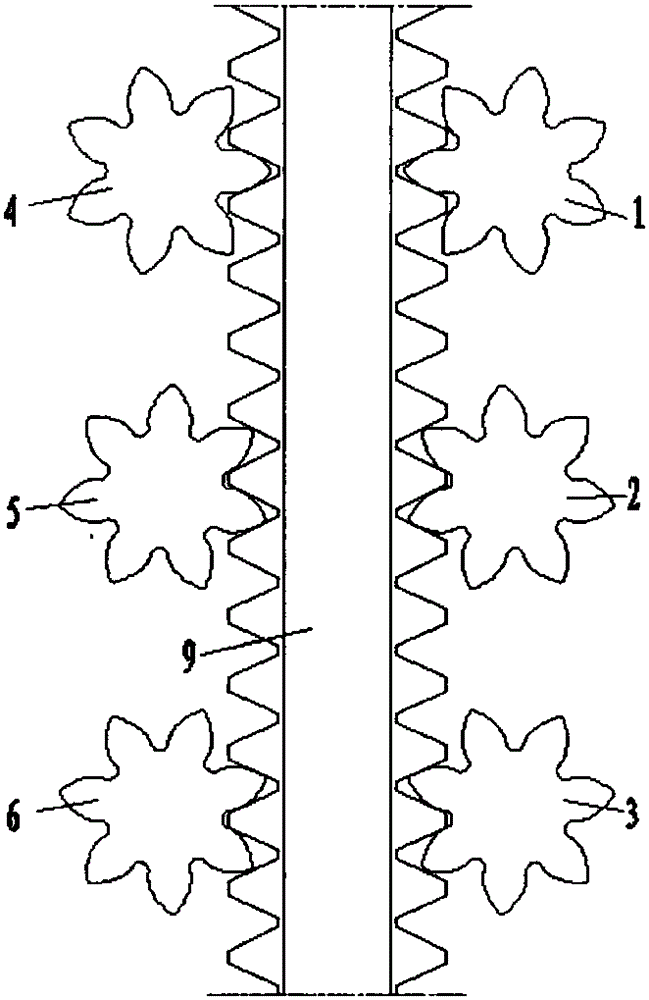

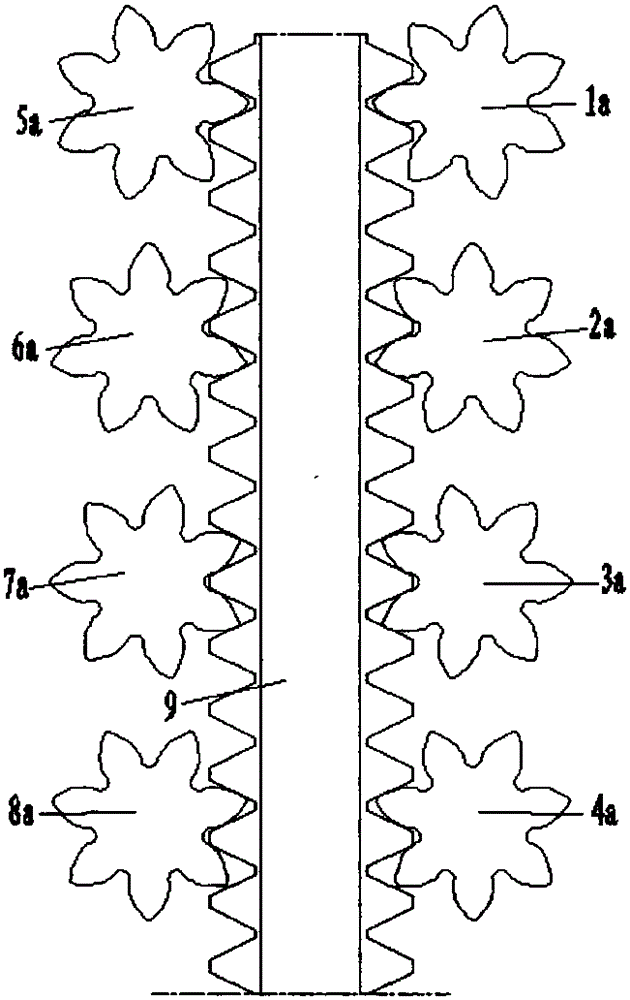

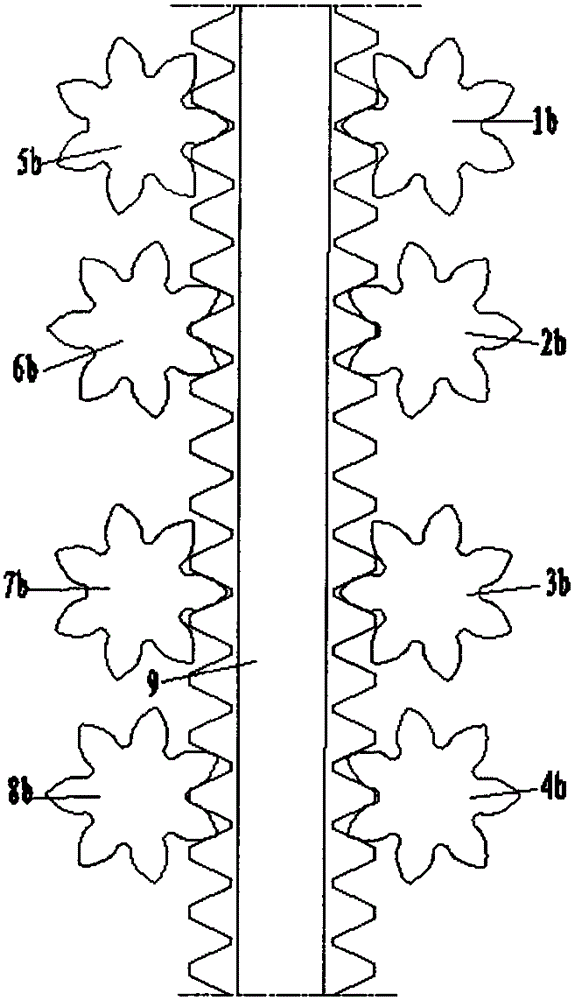

[0025] refer to figure 1 It is a schematic diagram of an embodiment in which the lifting mechanism is composed of three sets of driving pinion gear sets. Because the number of driving pinions on one side of the rack in the lifting mechanism is odd, the phase difference between adjacent driving pinions is 360 / (7x3)=17.14 ° , that is, between driving pinion 1 and driving pinion 2, between driving pinion 2 and driving pinion 3, between driving pinion 4 and driving pinion 5, and between driving pinion 5 and driving pinion 6 The phase difference is about 17.14 ° . The phase angle between the driving pinions at the same position on the opposite side of the rack is the same, so that the two horizontal radial forces generated by the two driving pinions are equal in size and opposite in direction to cancel each other.

[0026] There is an equal phase differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chamfer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com