Leakage point locating system of optical fiber sensing natural gas pipeline leakage monitoring system

A technology for natural gas pipelines and monitoring systems, applied in the field of leak point location systems, can solve the problems of being easily affected by environmental factors, high false alarm rate, low sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

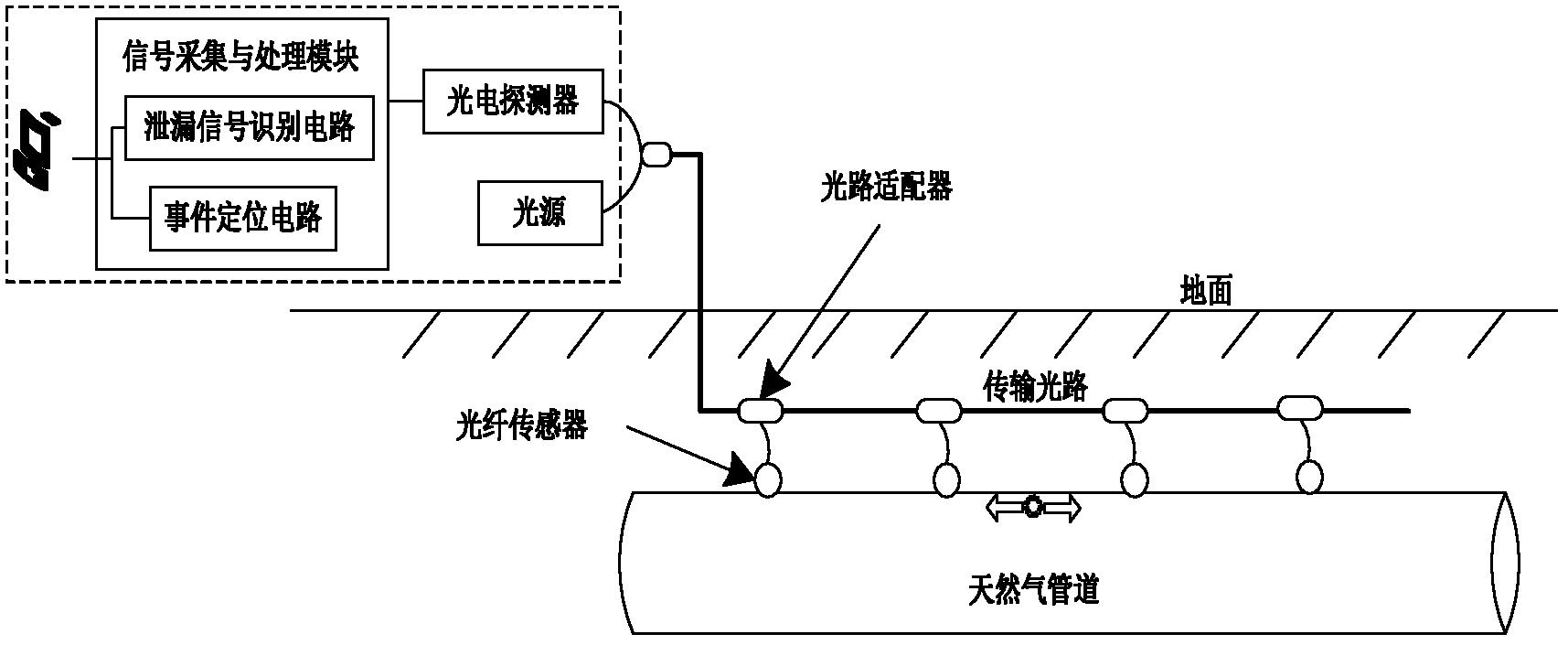

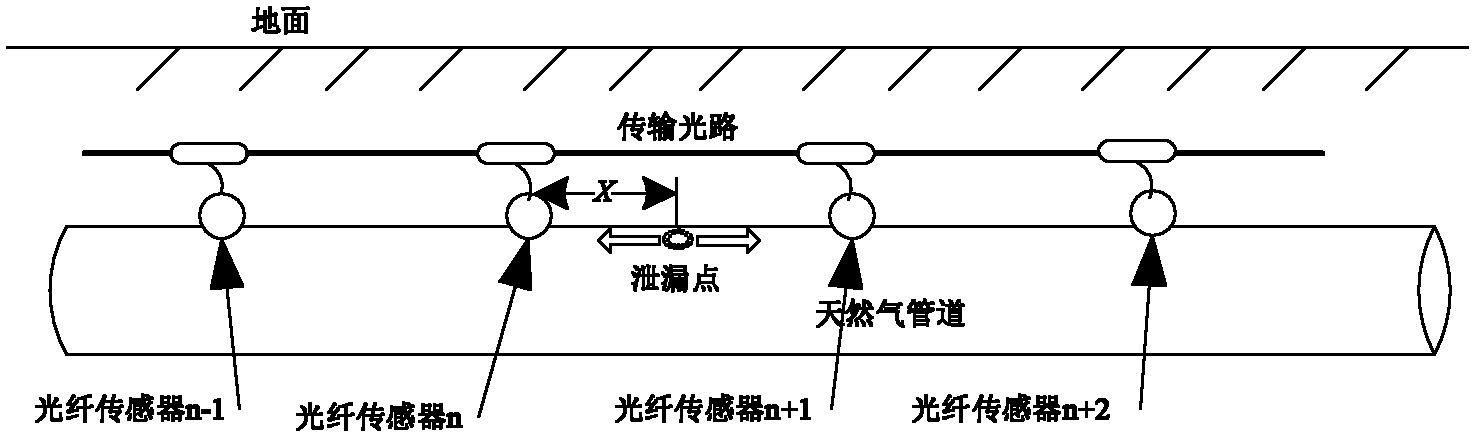

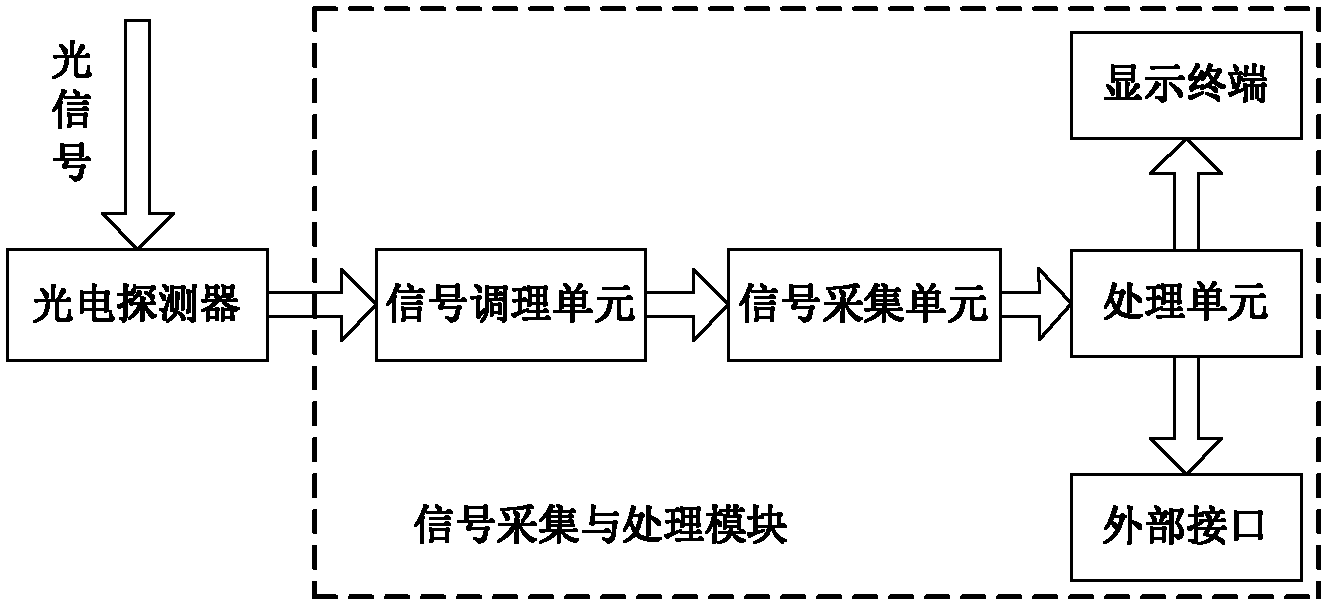

[0040] Embodiment. The composition of this example is as figure 1 As shown, an optical fiber sensor is installed at a certain distance on the pipeline body. Each optical fiber sensor is connected to the transmission optical path through the optical path adapter, and the transmission optical path is connected to the light source and photoelectric detector; the output of the photoelectric detector includes the functions of leakage signal identification and event location. The signal acquisition and processing module, the output of the signal acquisition and processing module is connected to the microcomputer through the external interface. After processing by the signal acquisition and processing module, the sensor based on the frequency division multiplexing method realizes the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com