Constant temperature and humidity system for chancery and adjusting method for constant temperature and humidity system

A technology of constant temperature and humidity, constant temperature and humidity machine, applied in the direction of air conditioning system, ventilation system, heating and ventilation control system, etc., can solve the problems of large energy loss, achieve load reduction, obvious energy saving effect, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

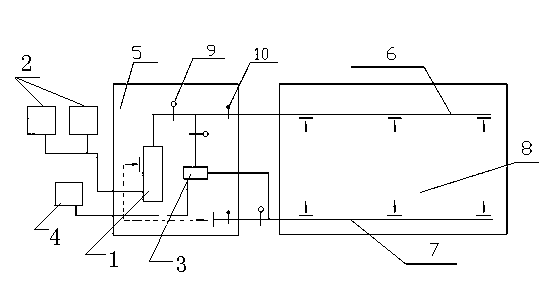

[0016] Embodiment 1, the present invention is described in further detail below. refer to figure 1 ,

[0017] A constant temperature and humidity system for archives. In the machine room 5, there is a constant temperature and humidity machine internal unit 1 (model: HF-50 Guangzhou Zhongyu Air Conditioning Technology Development Co., Ltd.), and multiple constant temperature and humidity machines can be connected in parallel outside the machine room. Machine 2, the air outlet of the internal unit of the constant temperature and humidity machine is connected with an air supply pipe 6, and the air supply pipe is introduced into the archives warehouse 8, and the air supply pipe 6 in the archives warehouse is provided with multiple air outlets. There is also a return air duct 7 with multiple air inlets, the return air duct 7 is introduced into the machine room 5, and the air outlet of the return air duct 7 is arranged in the machine room 5 and connected with the internal unit 1 of...

Embodiment 2

[0023] Example 2, the temperature and humidity standards in the warehouse are set as follows: summer: temperature 20°C, humidity 40%; winter: temperature 17°C, humidity 50%; increase the outlet water temperature of the constant temperature and humidity unit from 7°C to 17°C , all the other are identical with embodiment 1.

Embodiment 3

[0024] Example 3, the temperature and humidity standards in the warehouse are set as follows: summer: temperature 22°C, humidity 50%; winter: temperature 20°C, humidity 60%; the outlet water temperature of the constant temperature and humidity unit is increased from 7°C to 18°C , all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com