Monitoring method for remotely measuring and controlling damage depths of floor strata

A technology of remote measurement and control and damage depth, which is applied in the direction of measuring devices, earthwork drilling, instruments, etc., can solve the problems that cannot reflect the development and evolution law of rock formation damage at the base plate measuring point, the hydrophilicity of rock mass is different, and the measurement error is large. Achieve the effects of easy promotion and use, convenient instrument installation, and small reading error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

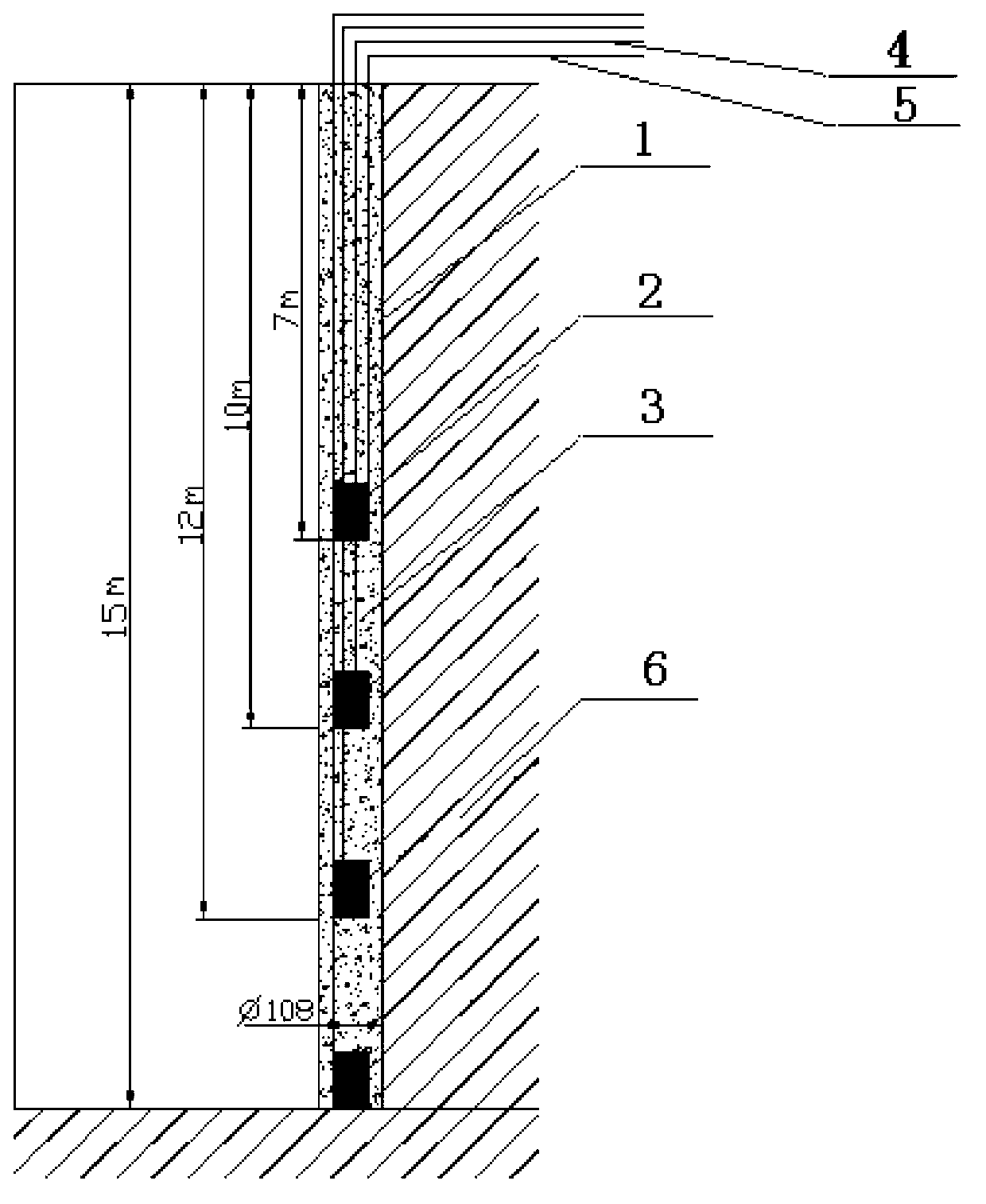

[0022] The present invention continuously monitors the damage status of the measuring point of the stope floor strata in the mining area before the top plate falls as the working face pushes through the monitoring point and after the working face pushes through the monitoring point during the mining process. The displacement and temperature of rock fractures are monitored.

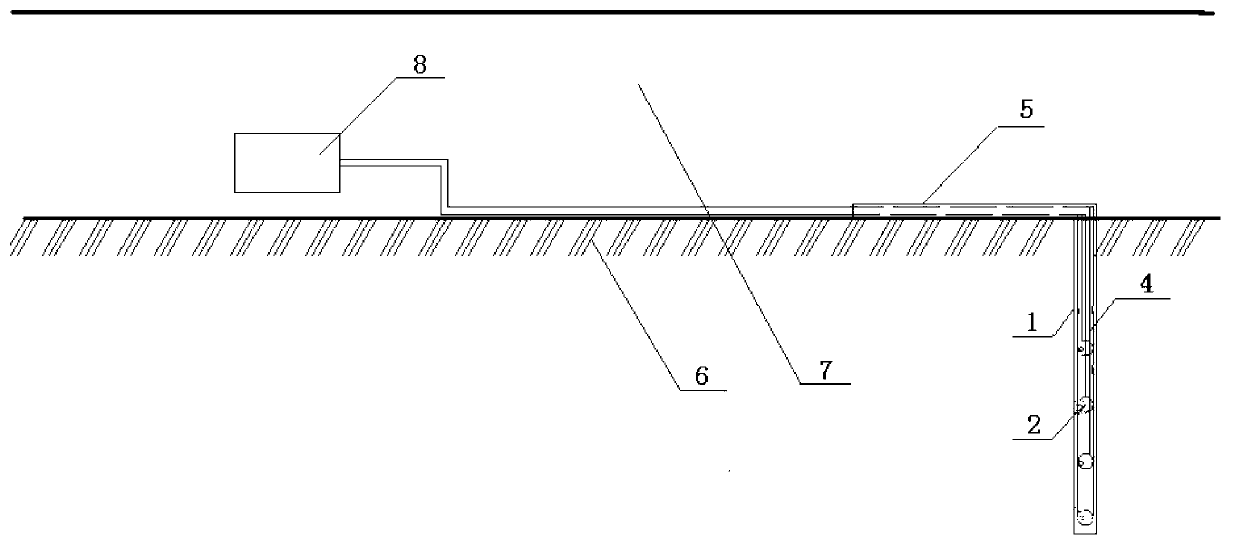

[0023] The monitoring system is composed of a vibrating wire rock fracture instrument buried in a drill hole of the coal seam floor, a temperature sensor, a signal acquisition unit, a signal transmission cable and a reading instrument.

[0024] In the present invention, at least four monitoring stations are respectively arranged at the place where the working face is pressed for the first time, the place where the working face is pressed for the first cycle, the place where the working face is pressed for the last cycle, and the place where the production line of the working face is stopped. The monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com