Dynamic balance device for blind hole part processing of slurry pump

A technology for parts processing and slurry pump, applied in the field of parts processing, can solve the problem of not being able to provide a balancing device, and achieve the effects of a wide range of weight, strong safety and reliability, and a wide range of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

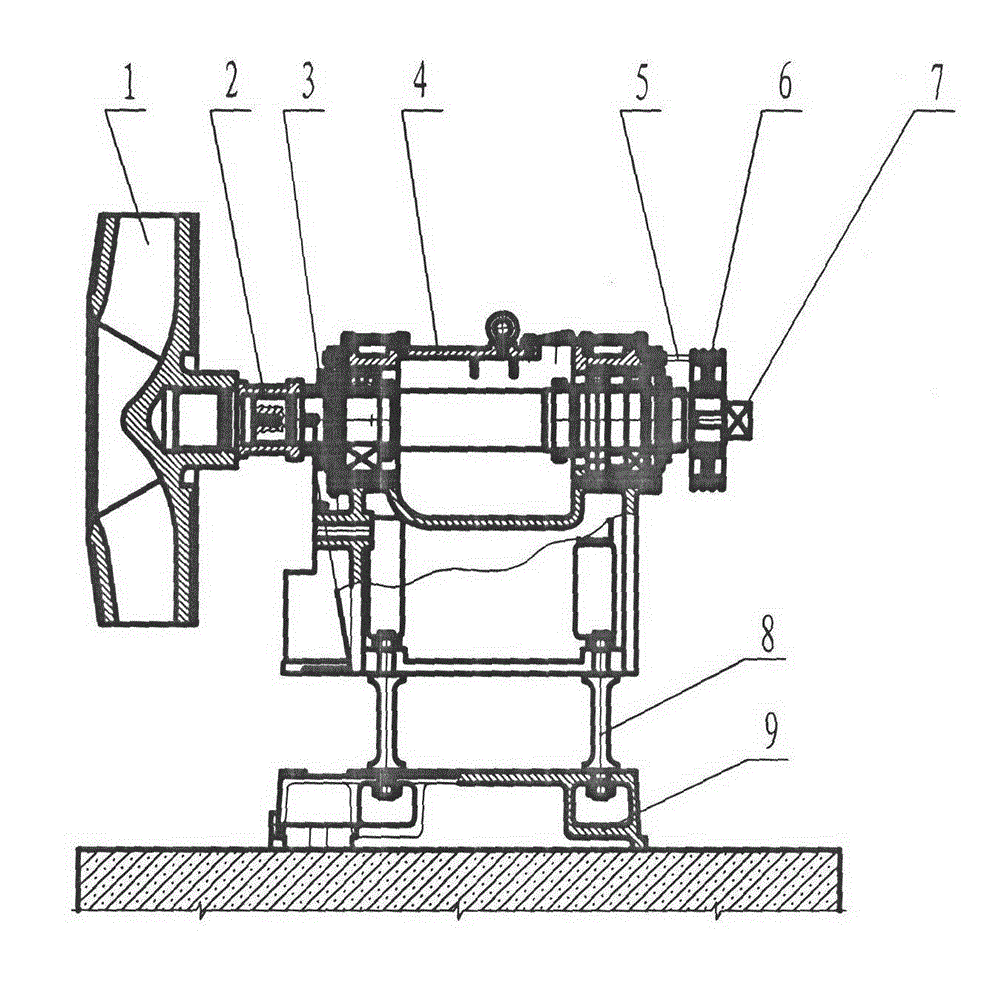

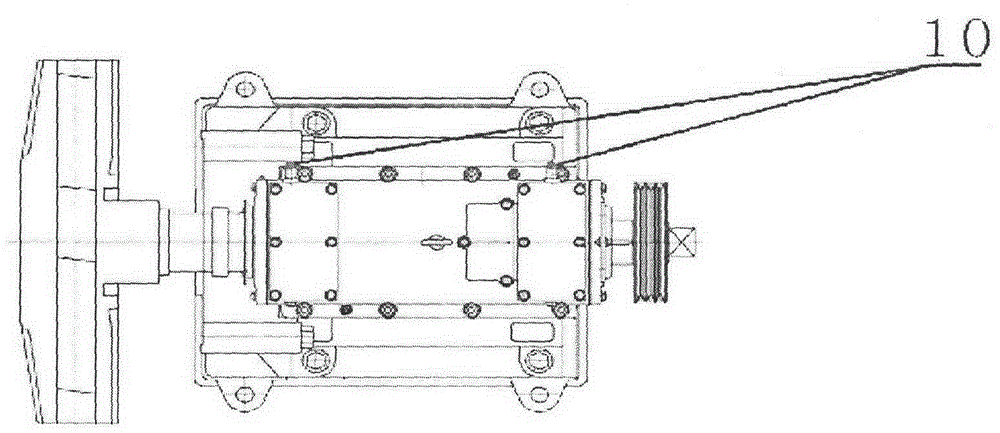

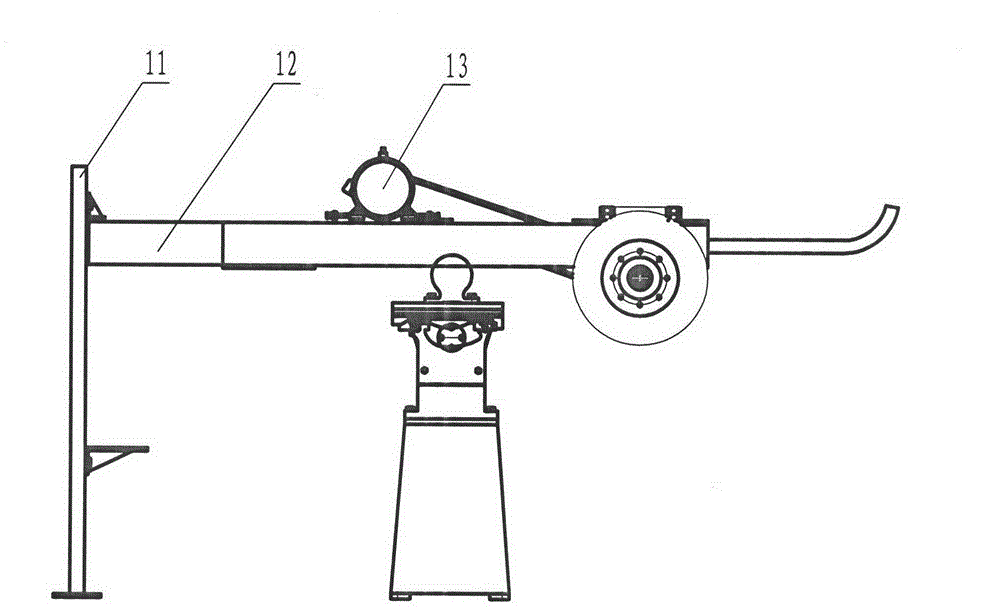

[0017] Attached below figure 1 to attach Figure 4 Examples of the present invention are illustrated, but not limited to the following examples:

[0018] A dynamic balance device for processing blind hole parts of a slurry pump is provided, which is composed of a bracket support component, a dynamic balance cutting component and the electric control cabinet component.

[0019] see figure 1 and figure 2 , the bracket support assembly includes a machine beam 8 arranged on the base 9, a bracket 4 is arranged on the machine beam 8, a rotating shaft 7 is arranged inside the bracket 4, and a joint is arranged at one end of the rotating shaft 7 2. The joint 2 is used to connect the rotating part 1, such as the impeller of the slurry pump; the other end of the rotating shaft 7 is connected to the pulley 6; the pulley 6 is used to drive the rotating shaft 7 and the rotation connected with the joint 2 The part 1 rotates together; the bracket 4 is also provided with a dial 3 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com