Experiment device for axial loading high-temperature stress corrosion test of metal material

A technology of axial loading and stress corrosion, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve problems such as leakage/leakage, achieve convenient loading and unloading of samples, and improve test efficiency , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Boiling point temperature medium solution stress corrosion test

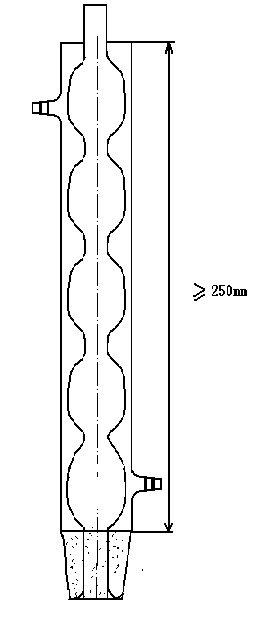

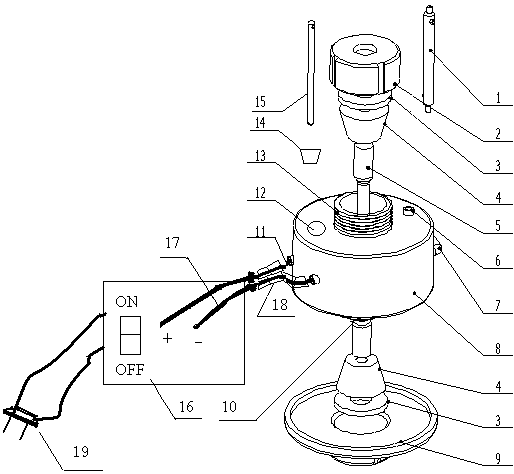

[0026] Take the stainless steel bellows boiling magnesium chloride stress corrosion test as an example. Measure the diameter (round sample) or length and width (plate sample) of the working part of the sample, calculate the cross-sectional area of the working part of the sample and the applied load; weigh an appropriate amount of magnesium chloride according to the size of the medium bottle and put it in in the medium bottle; figure 2Install the test environment device and samples on the loading testing machine; slowly add a small amount of high-purity water from the condenser port to submerge the magnesium chloride; press the terminal control switch to the "ON" position to start Heat the environment device; observe the test temperature during the process. When the temperature exceeds the required temperature, slowly add a small amount of high-purity water from the condenser mouth, and r...

Embodiment 2

[0027] Embodiment 2: Non-boiling point temperature medium solution stress corrosion test

[0028] Take the high-strength steel bolt 80 ℃ low concentration NaOH stress corrosion test as an example. Compared with Example 1, the difference is: (1) in accordance with the attached figure 2 Before installation, it is not necessary to weigh an appropriate amount of NaOH and put it into the medium bottle, but to prepare a NaOH solution of the corresponding concentration for use; (2) According to the attached figure 2 During installation, the 15 thermometer is not used, but the thermocouple of the 15 temperature control system; (3) After installation, what is poured from the condenser 12 is not high-purity water, but a prepared NaOH solution of corresponding concentration. (4) It is not necessary to add a small amount of high-purity water slowly from the condenser mouth repeatedly until the required temperature is reached. Other processes are the same as in Example 1.

[0029] Not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com