Temperature-protection built-in integrated direct-current motor driving circuit for toy

A technology for driving integrated circuits and DC motors, which is applied to starters of single DC motors, emergency protection circuit devices, DC motor speed/torque control, etc., and can solve the problems of many welding points, increased circuit temperature, and smoke from plastic packages and other issues to achieve the effect of reducing solder joints, reducing overall cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

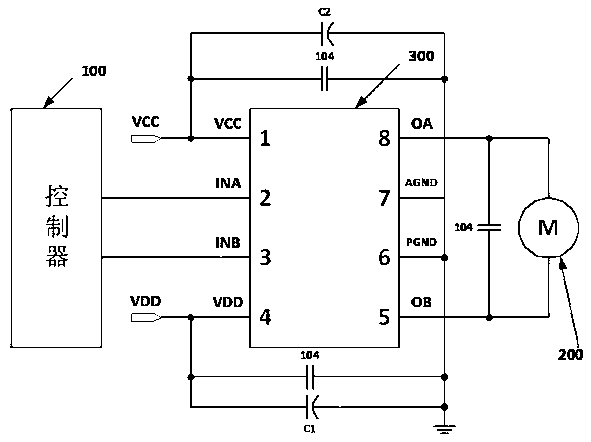

[0017] image 3 As shown, the driver integrated circuit 300 includes two input terminals INA, INB, two output terminals OA, OB, a logic control power supply terminal VCC, a power drive power supply terminal VDD, an analog ground, and a power ground. The two signals of the input terminals INA and INB are connected to the output of the controller, and the output terminals OA and OB are respectively connected to two ends of the DC motor. The logic control power supply VCC and the controller power supply are connected together, the power drive power supply VDD is directly connected to the drive power supply, and the analog ground and the power ground are connected together through the PCB board.

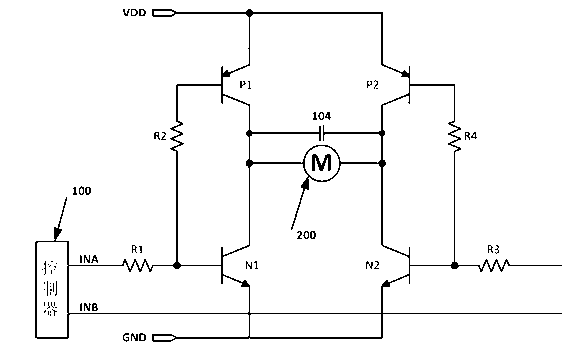

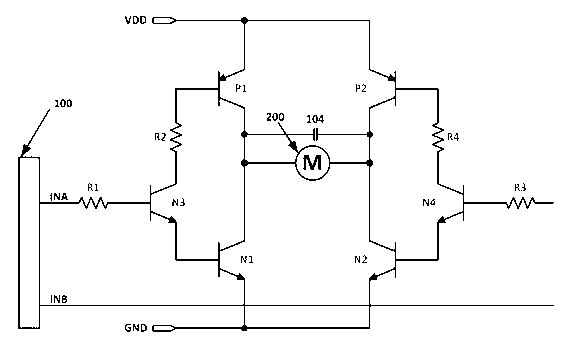

[0018] image 3 As shown, a specific implementation circuit schematic diagram of the DC motor drive integrated circuit 300 is shown in Figure 4 as shown, Figure 4 A series of logic gates realize the control of the input signal to the output signal. When the temperature of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com