Medicine extraction device and technique thereof

An extraction device and drug technology, applied in the direction of solid solvent extraction, etc., can solve the problems of reduced concentration efficiency, easily damaged vacuum equipment, solvent loss, etc., and achieve the effect of reducing evaporation and avoiding pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

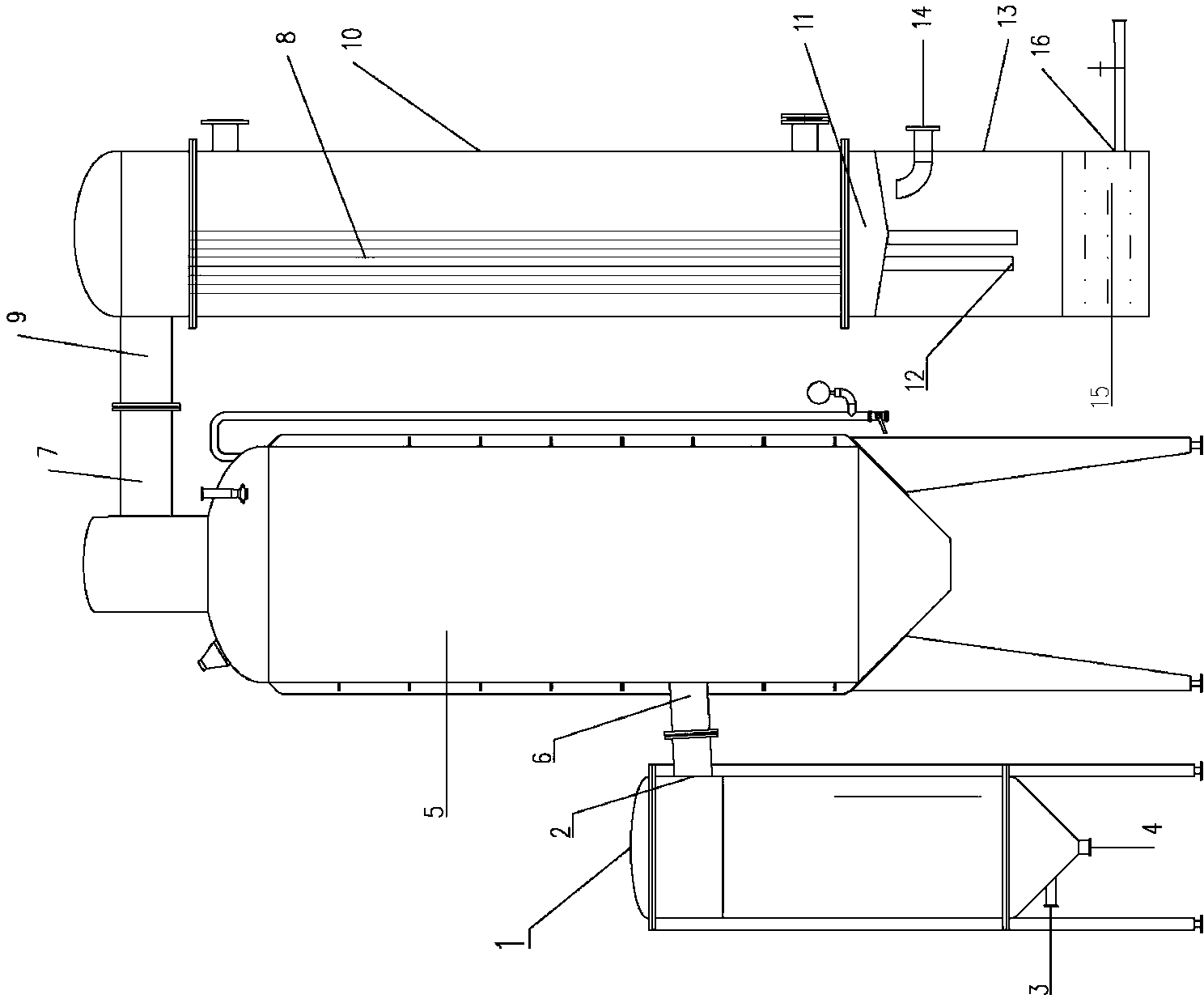

[0055] The drug extraction device described in this embodiment is as figure 1 and 2 As shown, it includes a first extraction tank and a first concentrator, the first extraction tank is provided with a solvent inlet and a liquid outlet, and the first extraction tank is any commercially available drug extraction tank, in this embodiment , the solvent inlet of the first extraction tank is arranged on the top of the tank body, and the liquid outlet of the first extraction tank is arranged at the bottom of the tank body; the first concentrator includes: a heater 1, the heater 1 is provided with feed port 3, and described heater 1 is any commercially available heater, and the feed port 3 of described heater 1 is arranged at the bottom of heater 1 in the present embodiment, and described first extraction The liquid outlet of the tank communicates with the feed port 3 of the heater 1; the bottom of the heater 1 is provided with a concentrated material outlet 4, and the upper part is ...

Embodiment 2

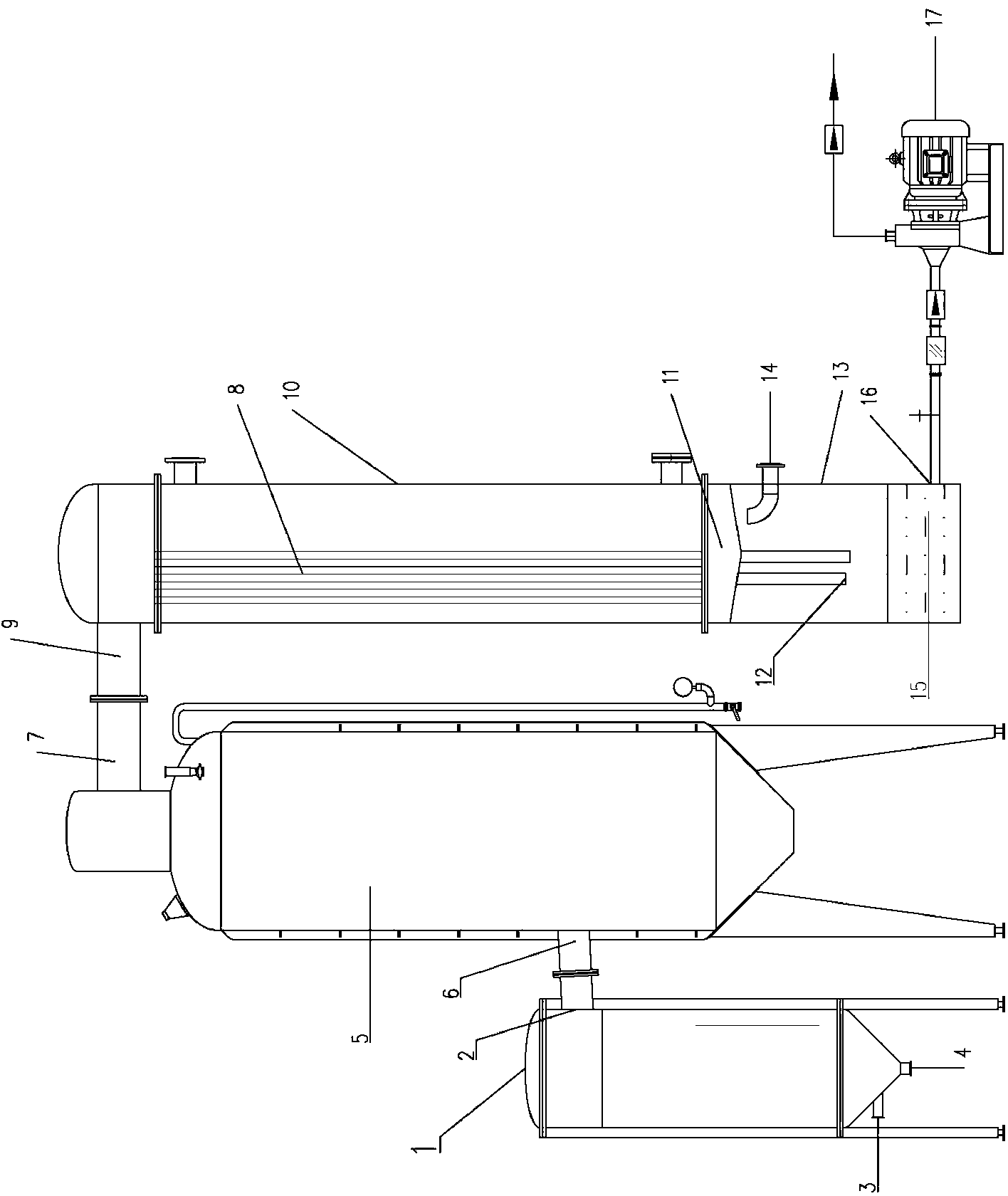

[0063] The drug extracting device of the present embodiment is based on embodiment 1, such as image 3 As shown, the distance between the vacuum pipe 14 and the outlet 12 of the outlet pipe is 700 m, and the outlet 16 is connected with a drainage pump 17 . Through the drainage pump 17, the condensate in the liquid collector 13 can be discharged in time without destroying the vacuum degree in the drug extraction device, which avoids the adverse effect of the change of the vacuum degree on the operation of the device, saves energy, and simplifies the operation. The efficiency of device operation is improved.

Embodiment 3

[0065] The drug extracting device of the present embodiment is based on the above-mentioned embodiment, such as Figure 4 As shown, it also includes a liquid receiving tank 18, and its shape can be arbitrarily selected according to the actual situation. The liquid receiving tank 18 is arranged below the liquid collector 13. In this embodiment, the bottom of the liquid collector 13 is the receiving tank. The top of the liquid tank 18, the liquid receiving tank 18 is provided with a liquid inlet 19 and a liquid outlet 20, and the liquid discharge port 16 of the liquid collector 13 passes through the liquid inlet 19 and the liquid receiving tank 18 The inside is connected; the distance between the vacuum tube 14 and the outlet pipe outlet 12 becomes 900m. In this embodiment, the bottom of the liquid collector 13 is an inverted cone, and its discharge port 16 is arranged on the inverted cone. At the bottom, the liquid inlet 19 of the liquid receiving tank 18 is arranged on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com