Electrostatic dust remover for continuously winding and moving dust collecting plates

A technology for electrostatic dust removal and dust collection board, applied in the field of electrostatic dust removal devices, can solve problems such as complex structure, and achieve the effects of increasing dust collection area, efficient collection, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

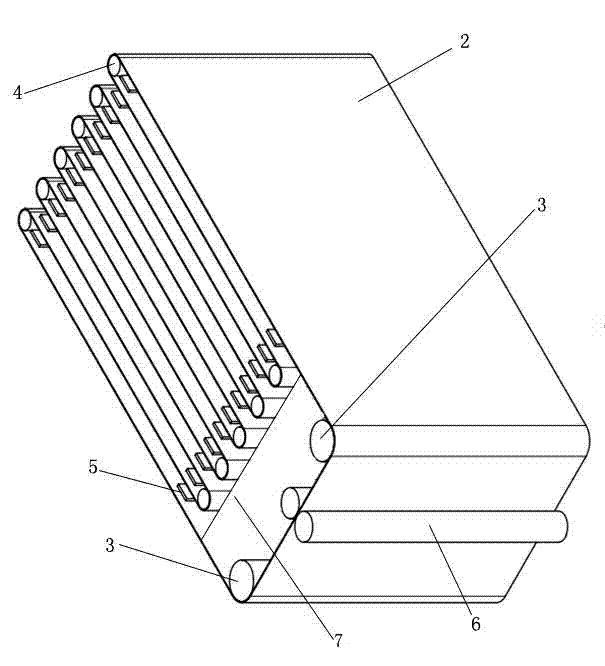

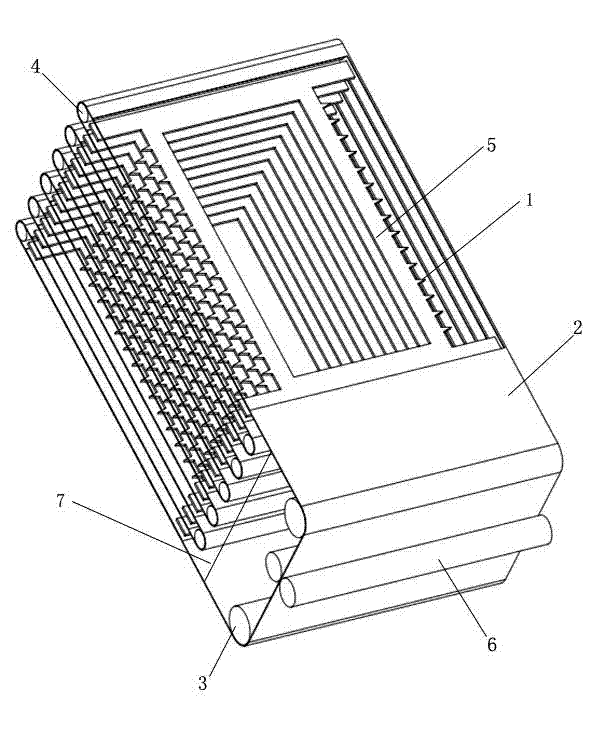

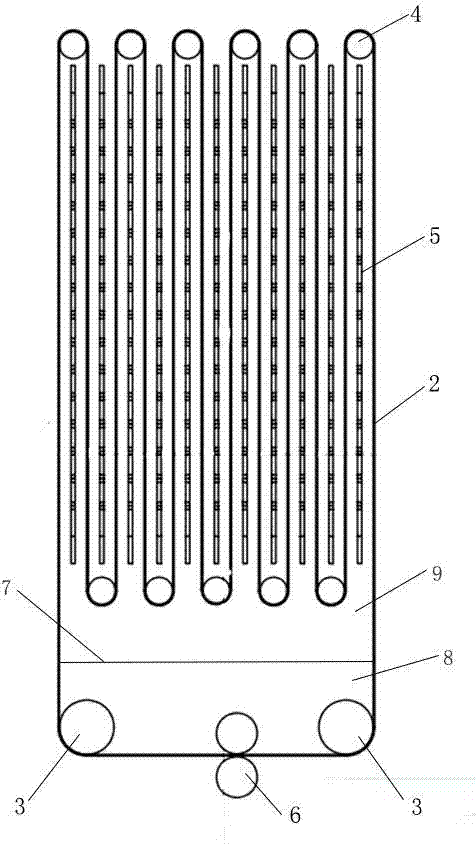

[0029] Such as Figure 1 to Figure 3 As shown, the continuous winding mobile dust collecting plate type electrostatic precipitator includes a dust collector with a dust suction device, a discharge electrode 5 and a dust collection electrode are arranged inside the dust collector shell, and a high voltage The power supply device, wherein the dust-collecting electrode is a flexible belt-shaped dust-collecting plate 2, and the dust-collecting plate 2 is wound on a guide roller, and the guide roller includes a driving guide roller 3 and an inductive guide roller 4 , wherein there are multiple inductive guide rollers 4, which are divided into two layers and arranged in parallel at equal distances. The dust collecting plates 2 are continuously wound on the upper and lower corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com