Titanium and titanium alloy bar hot continuous rolling production line and production process

A titanium alloy, hot continuous rolling technology, applied in metal rolling and other directions, can solve the problems of difficult deformation, poor dimensional accuracy, low production efficiency, etc., and achieve the effect of ensuring internal structure and performance, reducing deformation heat, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

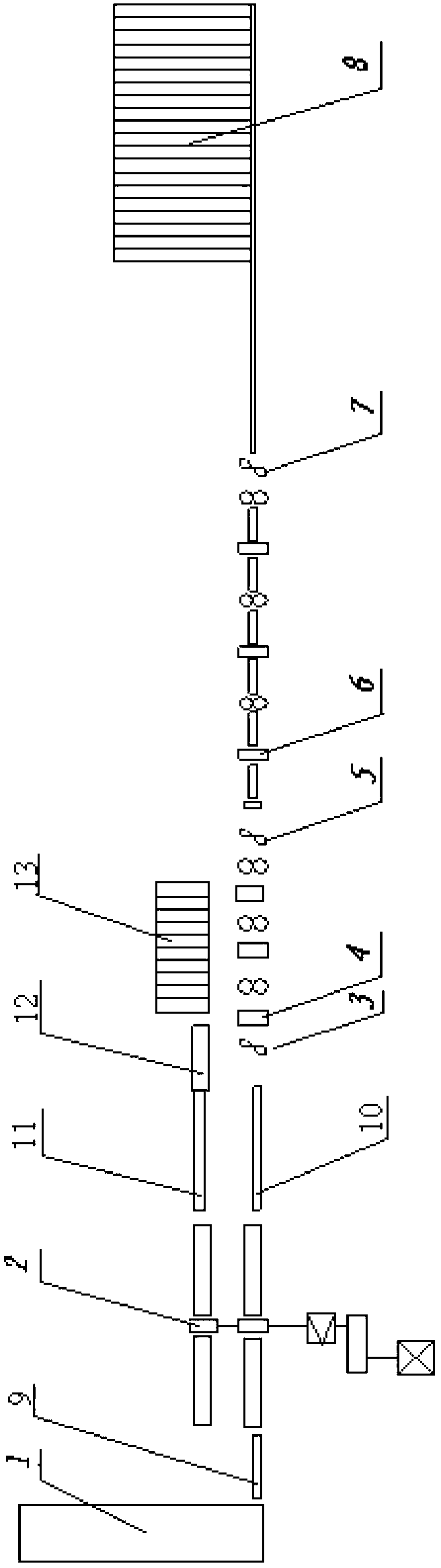

[0017] Attached below figure 1 Embodiments of the present invention are described.

[0018] The continuous hot rolling production line for titanium and titanium alloy bars consists of heating furnaces connected longitudinally in sequence 1, horizontal two-roll rough rolling unit 2, high-rigidity short-stress line tandem two-roll intermediate rolling unit 4, high-rigidity short-stress line tandem Two-roll pre-finishing unit 6 and small bar cooling bed 8; the discharge port of heating furnace 1 is connected to the feed port of row-type two-roll rough-rolling unit 2 through conveying roller table I9, and the row-type two-roll rough-rolling The first discharge port of unit 2 is connected to the feed port of the high-stiffness short-stress line tandem two-roll intermediate rolling unit 4 through the conveying roller table II10, and the end of the conveying roller table II10 is connected to the high-rigidity short-stress line tandem two-roll intermediate A cutting shear 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com