Collapsible power assembly for coiler mandrel

A powertrain and machine reel technology, applied in the field of expansion and contraction powertrain, can solve the problems of increasing the axial size of the expansion and contraction powertrain, not being able to adapt to the axial installation space, complex structure, etc., to achieve volume reduction, shaft The effect of decreasing the axial length and reducing the overall axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

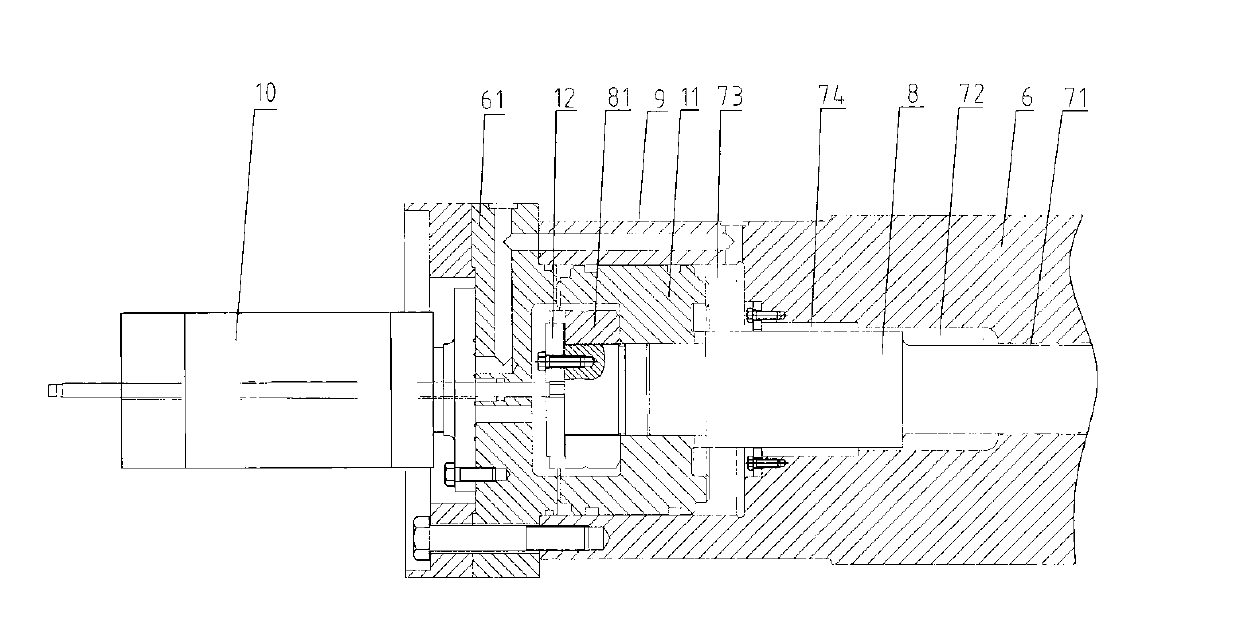

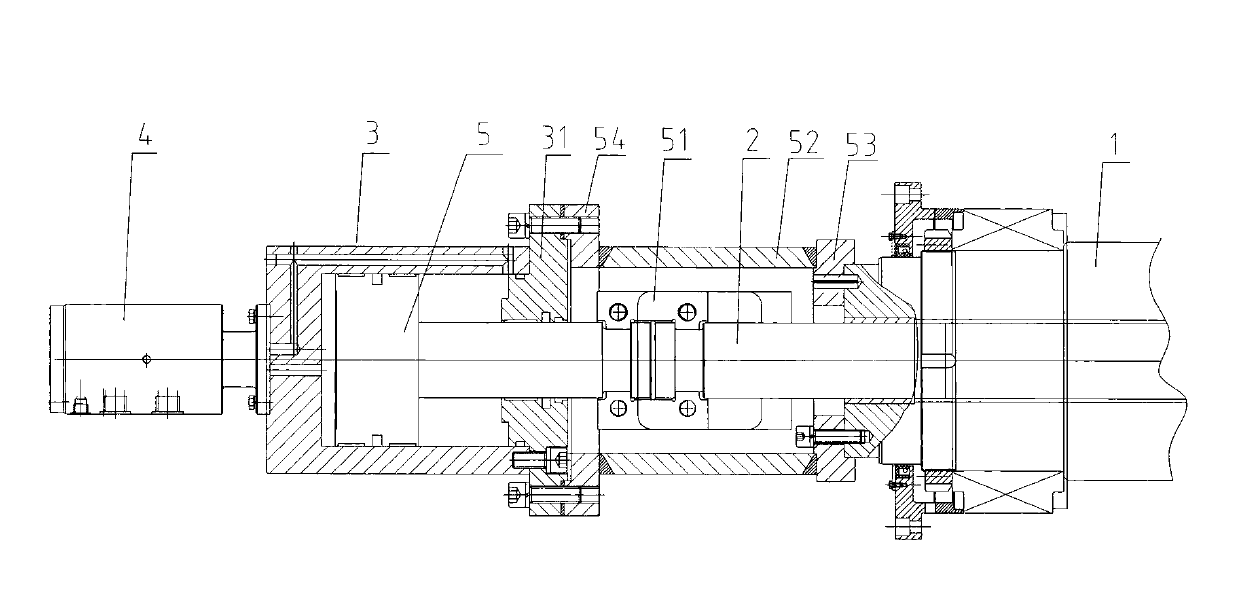

[0016] like figure 2 As shown, an expansion and contraction power assembly for a coiler reel includes a tie rod 8 installed in the shaft hole of the main shaft 6, an expansion and contraction oil cylinder 9 integrated with the main shaft 6, and an expansion and contraction oil cylinder 9 installed on the main shaft 6 The rotary joint 10 on the side end surface of the back main shaft 6, the shaft hole of the main shaft 6 is in the shape of a step with a diameter gradually increasing from the expansion and contraction cylinder 8 to the rotary joint 10, and is divided into a first shaft hole 71, a second shaft hole 72 and a second shaft hole in turn. Three shaft holes 73, most of the tie rod 2 are located in the first shaft hole 71 and the second shaft hole 72, the third shaft hole 73 is the oil chamber of the expansion and contraction cylinder 9, and the oil chamber of the expansion and contraction cylinder 9 is equipped with a piston 11. There is a through hole in the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com