A kind of copper mold for preparing bulk amorphous alloy and the preparation method of copper mold

An amorphous alloy and copper mold technology is applied in the field of copper molds for preventing the hollowing of bulk amorphous alloys prepared by vacuum suction casting method and the field of preparation thereof, which can solve problems such as poor uniformity and compactness, and achieve excellent performance and uniform tension. , cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

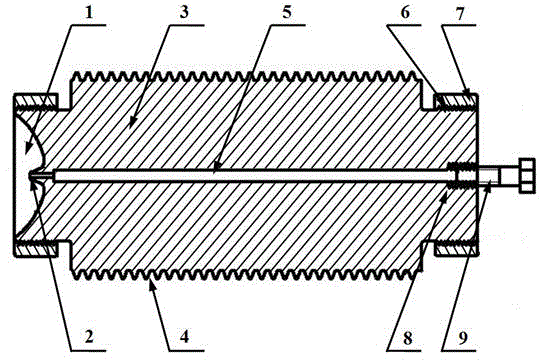

[0020] The structure diagram of the present invention is as figure 1 As shown, the copper mold for preparing bulk amorphous alloys of the present invention includes a melting cavity 1, a suction casting port 2, a copper mold 3, and a cavity 5, wherein one end of the copper mold 3 is provided with a melting cavity 1 , The smelting cavity 1 is provided with a suction casting port 2, and the geometric center of the copper mold 3 is provided with a cavity 5.

[0021] The above-mentioned suction casting port 2 is arranged at the end of the smelting cavity 1 . In this embodiment, the suction casting port 2 is arranged at the lowest position at the end of the melting cavity 1 .

[0022] The above-mentioned suction casting port 2 is a crater-shaped suction casting port. The water-cooled copper mold of the present invention is based on the traditional water-cooled copper mold, at the bottom of the concave ball crucible-shaped smelting concave cavity 1 for smelting alloys, the copper ...

specific Embodiment

[0034] Implementation example 1:

[0035] 1. Put Zr with a purity of 99.8%, Cu with a purity of 99.5%, Ni with a purity of 99.98% and Al with a purity of 99.5% as Zr 55 Cu 30 Ni 5 Al 10 The nominal ingredients are batched and placed in the electric arc furnace;

[0036] 2. Vacuum the electric arc furnace, when it reaches 3×10 -3 After the vacuum degree of Pa is filled with argon to an atmospheric pressure, under the protection of argon, the titanium is first melted to absorb residual oxygen, and then the alloy is smelted for 3~5 times to form a master alloy;

[0037] 3. According to the shape and size of the prepared sample, calculate the theoretical mass of the required master alloy, then break the master alloy, weigh the master alloy fragments of the corresponding quality, and move it to the concave spherical crucible-shaped smelting concave at the upper end of the water-cooled copper mold of the present invention. Cavity;

[0038] 4. Start the arc to melt the master...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com