Positioning method and positioning system for back barrier material of sheet shear or bending machine

A positioning method and backgauge technology, applied in positioning devices, shearing machine accessories, shearing devices, etc., can solve the problems of unsatisfactory high-precision processing, unsatisfactory positioning effect, high cost, etc., and achieve easy maintenance and reduce The effect of equipment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

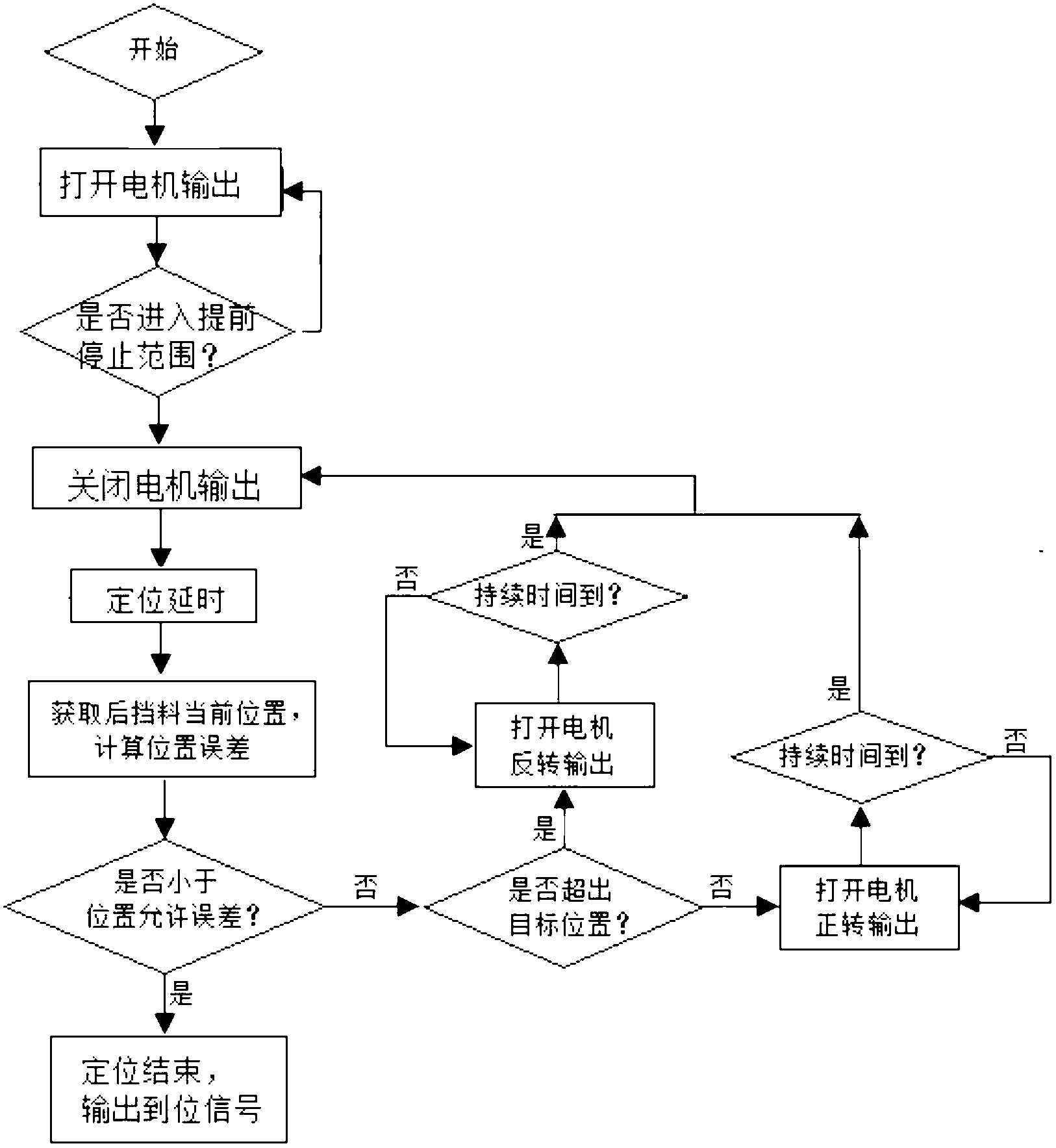

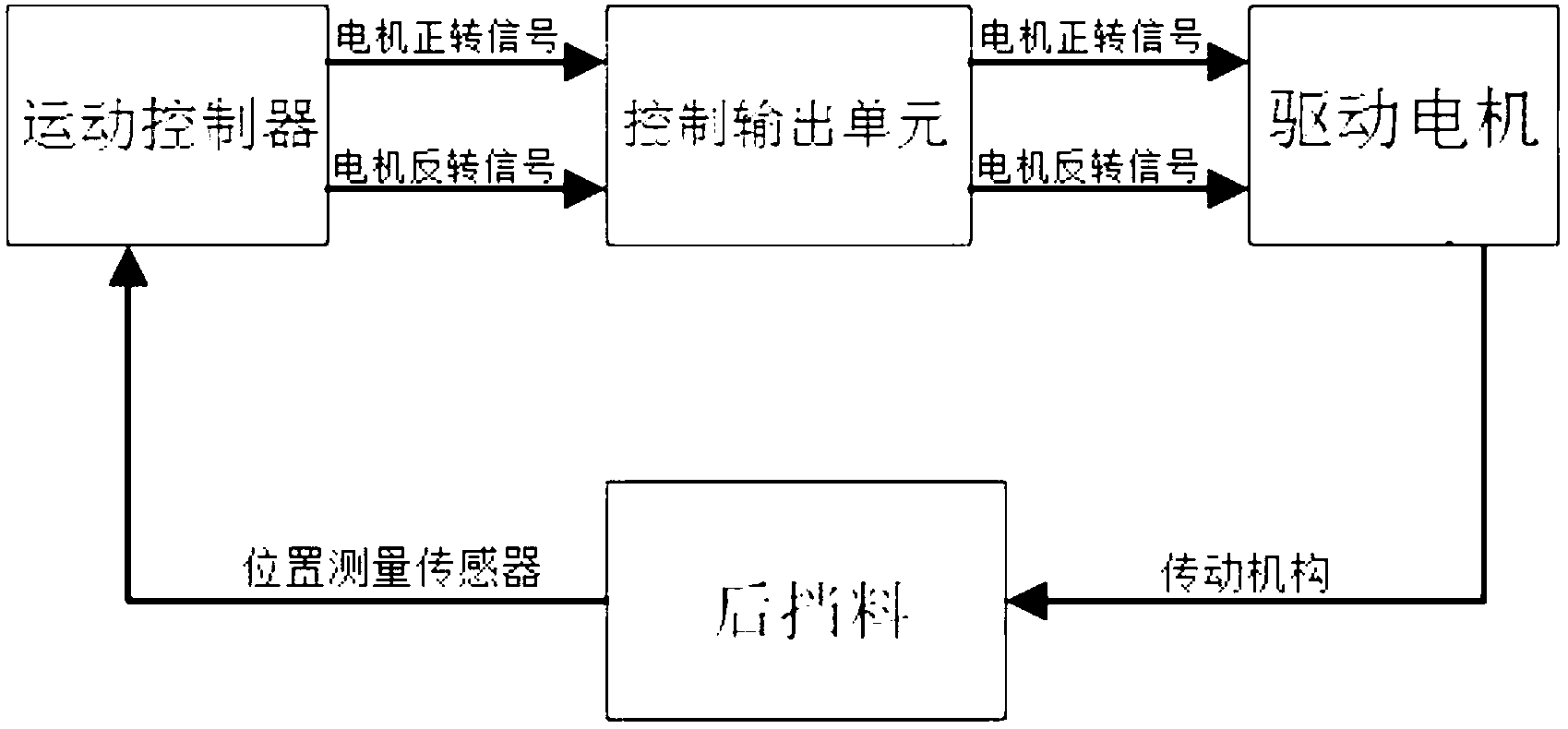

[0040] First set the target position to 300.00mm; set the in-position tolerance to 0.02mm; set the early stop distance to 5.00mm; set the OutTime to 20ms, and set the WaitTime to 2s;

[0041] After the parameters are set, start the system and use IO to directly control the asynchronous motor to drive the back gauge. Assume that the current position is 500.00mm. When the back gauge moves to the target position of 300.00mm, when the back gauge position enters Within the range of early stop, that is, at 295.00mm, turn off the motor output, so that the back gauge continues to run to the target position by inertia, and calculate the error ε between the actual position and the target position when the back gauge stops completely;

[0042]Assuming that the actual position CurPos is 301.00mm at this moment, the error ε=1.00mm, which is greater than ε1, the system judges that the positioning does not meet the positioning accuracy requirements and has exceeded the target position; the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com