Trolley type steel coil transport system

A transportation system and trolley-type technology, which is applied in the field of steel rolling, can solve the problems of heavy equipment weight, large maintenance and repair, complex roller table structure, etc., achieve the effect of light equipment weight, less maintenance, and improve the installed capacity of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

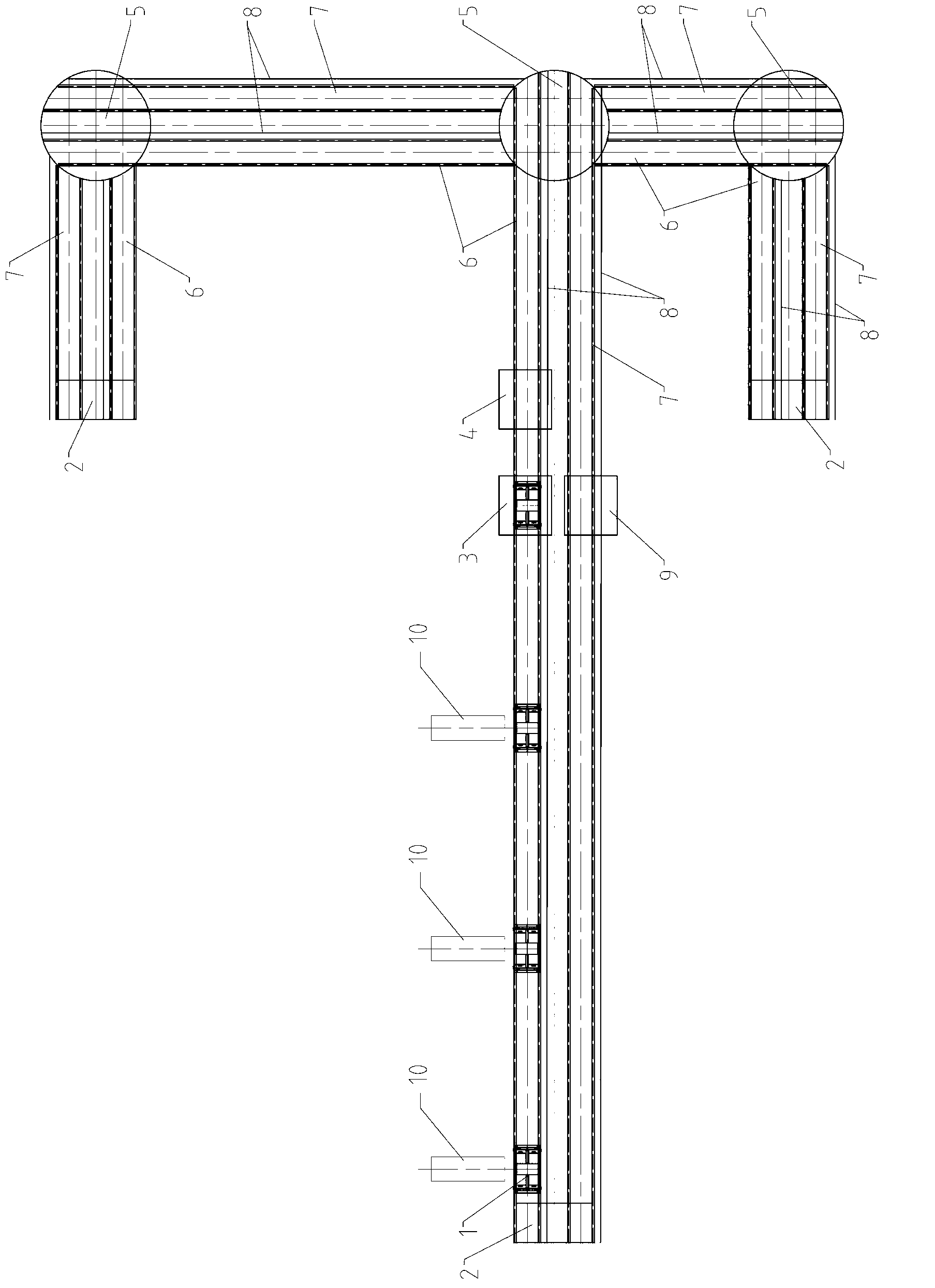

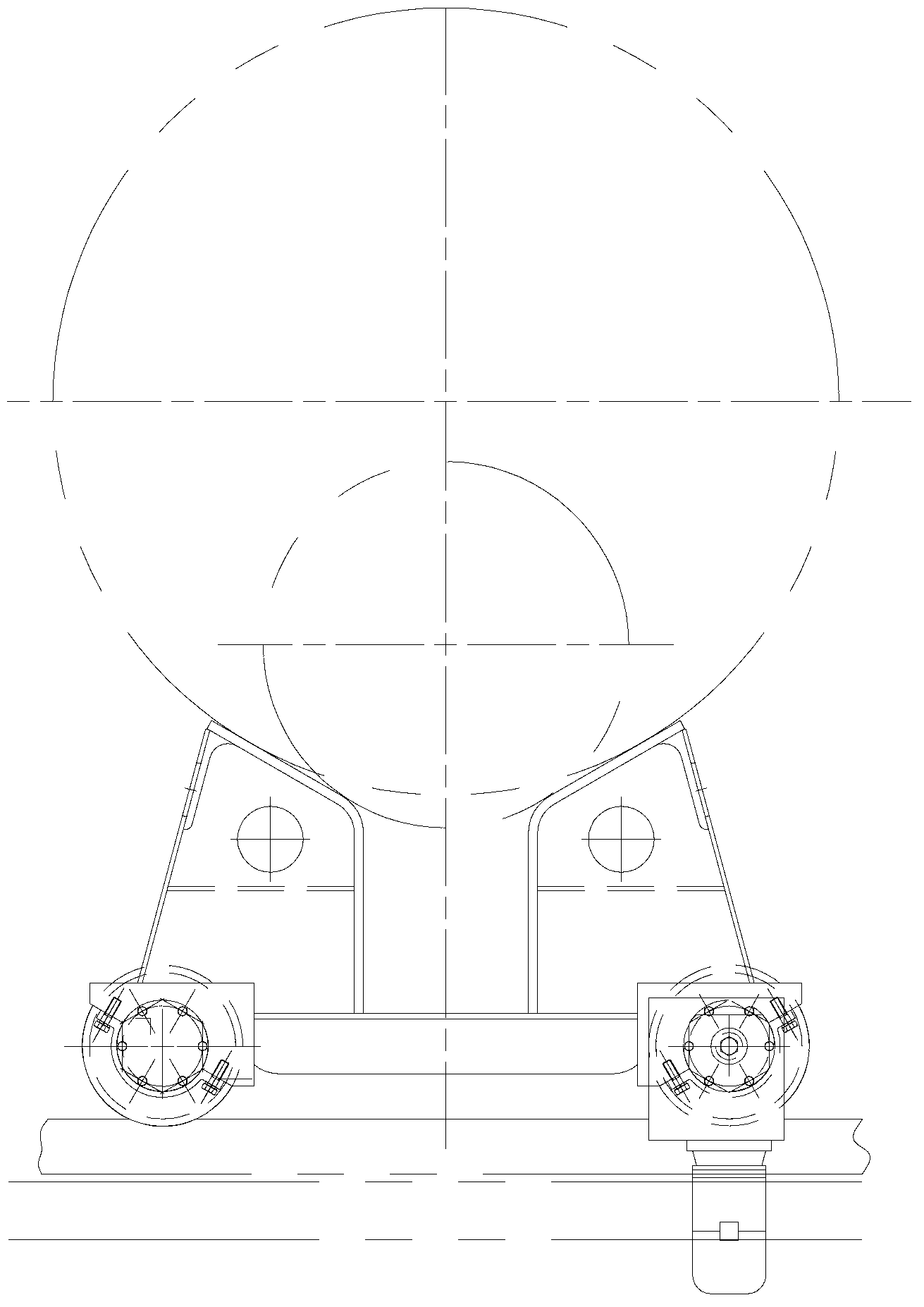

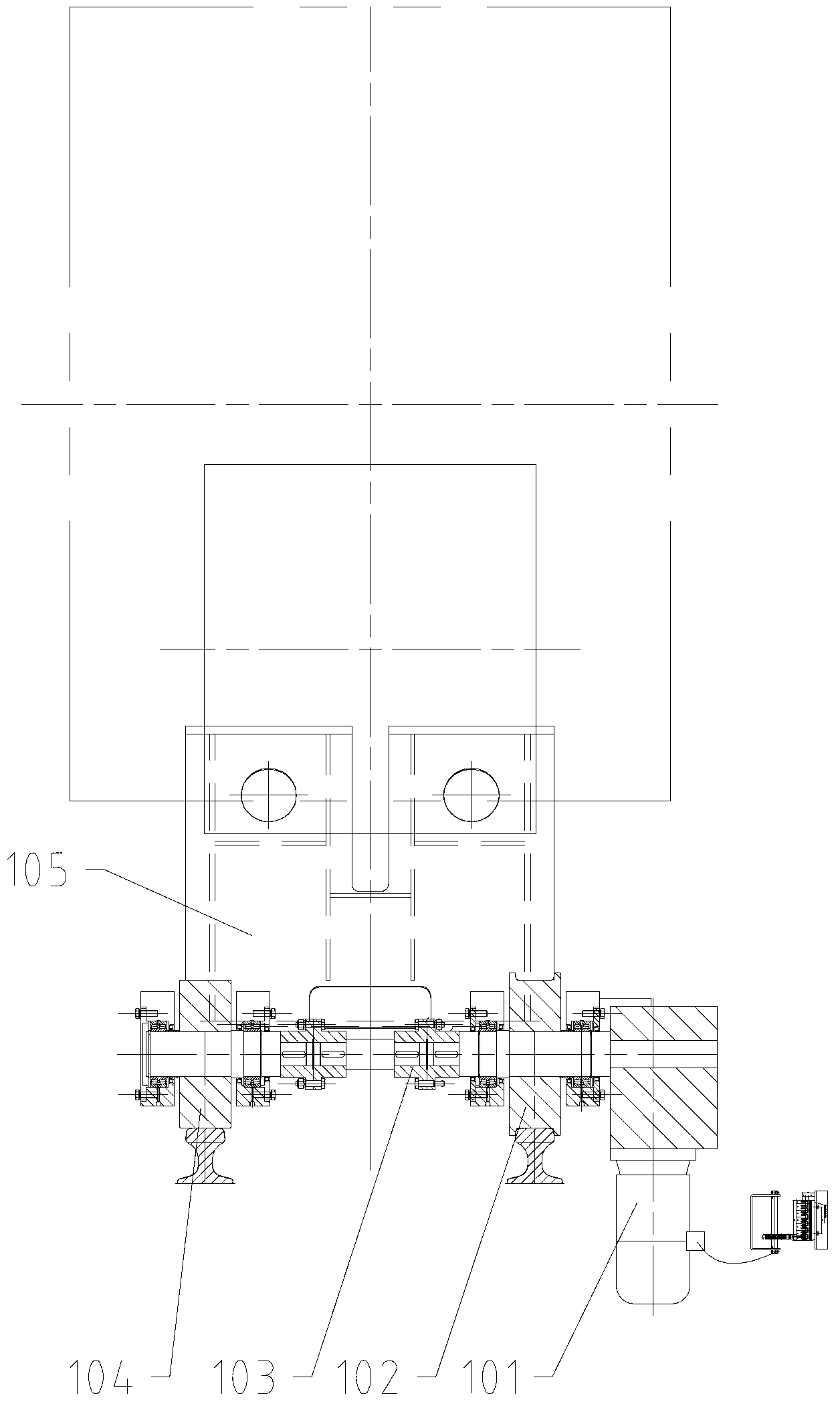

[0036]Trolley-type steel coil transport system, including trolley for transporting steel coils (1), traverse device (2), heavy-duty lifting device (3), weighing device (4), slewing device (5), heavy-duty track (6), light-load track (7), trolley line group (8) and light-load lifting device (9). The trolley 1 runs on the track, and the trolley 1 includes a trolley driving device 101, a guide wheel 102, a power transmission shaft 103, a support wheel 104 and a saddle 105, and the saddle 105 is two rigid blocks with inclined surfaces on the top. The inclined surface of the saddle 105 is relatively installed, and the trolley driving device 101 includes a motor-reducer mechanism; the track includes a heavy-duty track 6 and a light-duty track 7, and the trolley carries steel coils on the heavy-duty track 6, and the empty trolley runs on the light-duty track. The load track 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com