Method for separating oil slick of waste cold-rolling fluid

A technology of oil separation and cold rolling liquid, which is applied in the direction of separation method, liquid separation, grease/oily substance/floating matter removal device, etc. It can solve the problems of clogging the oil discharge hole of the separator, achieve good effect, high promotion value, Method reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

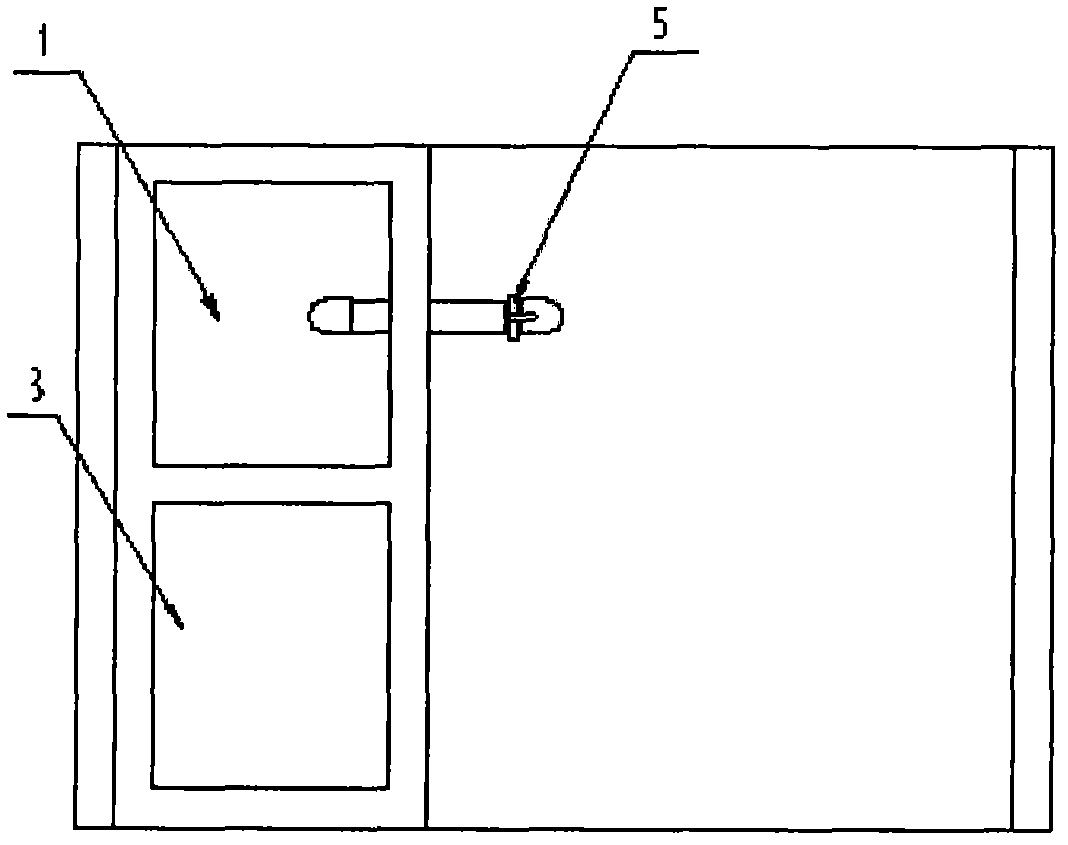

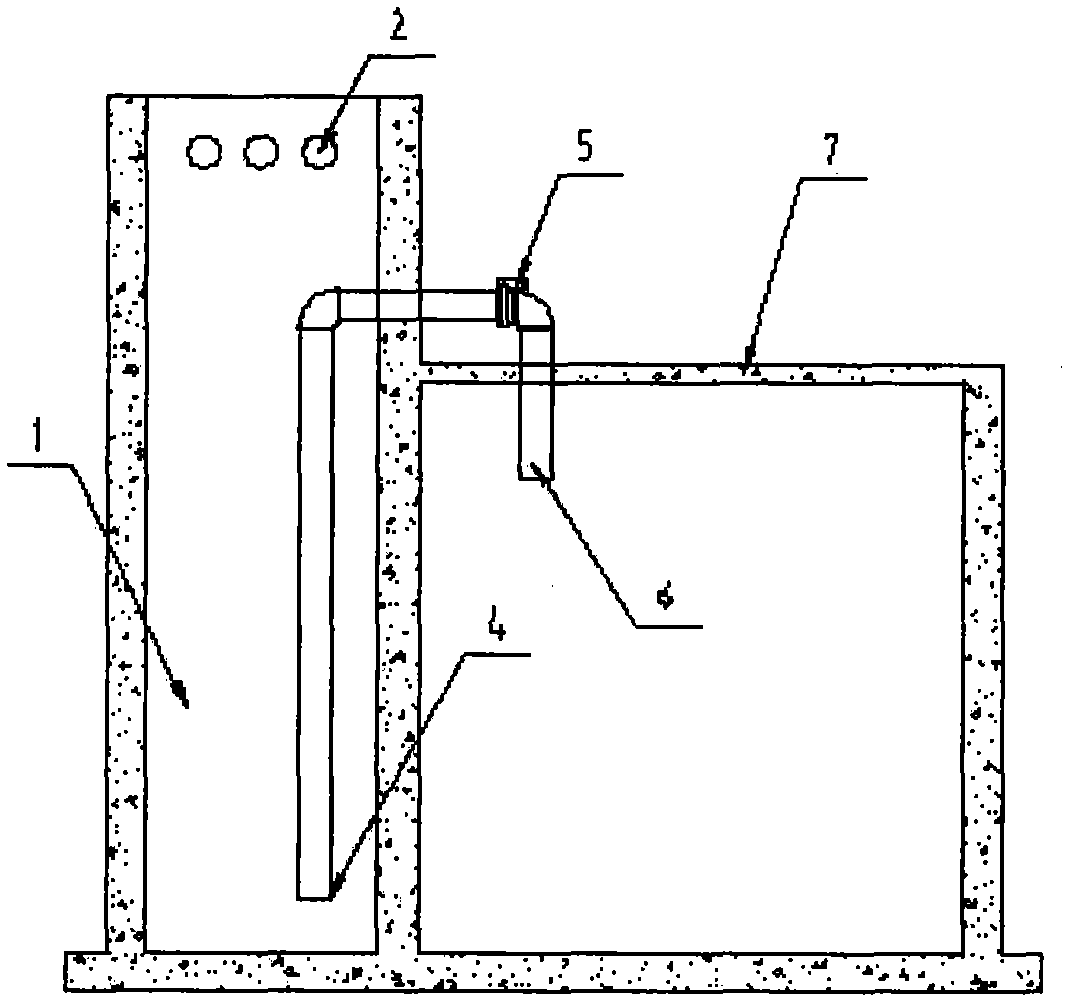

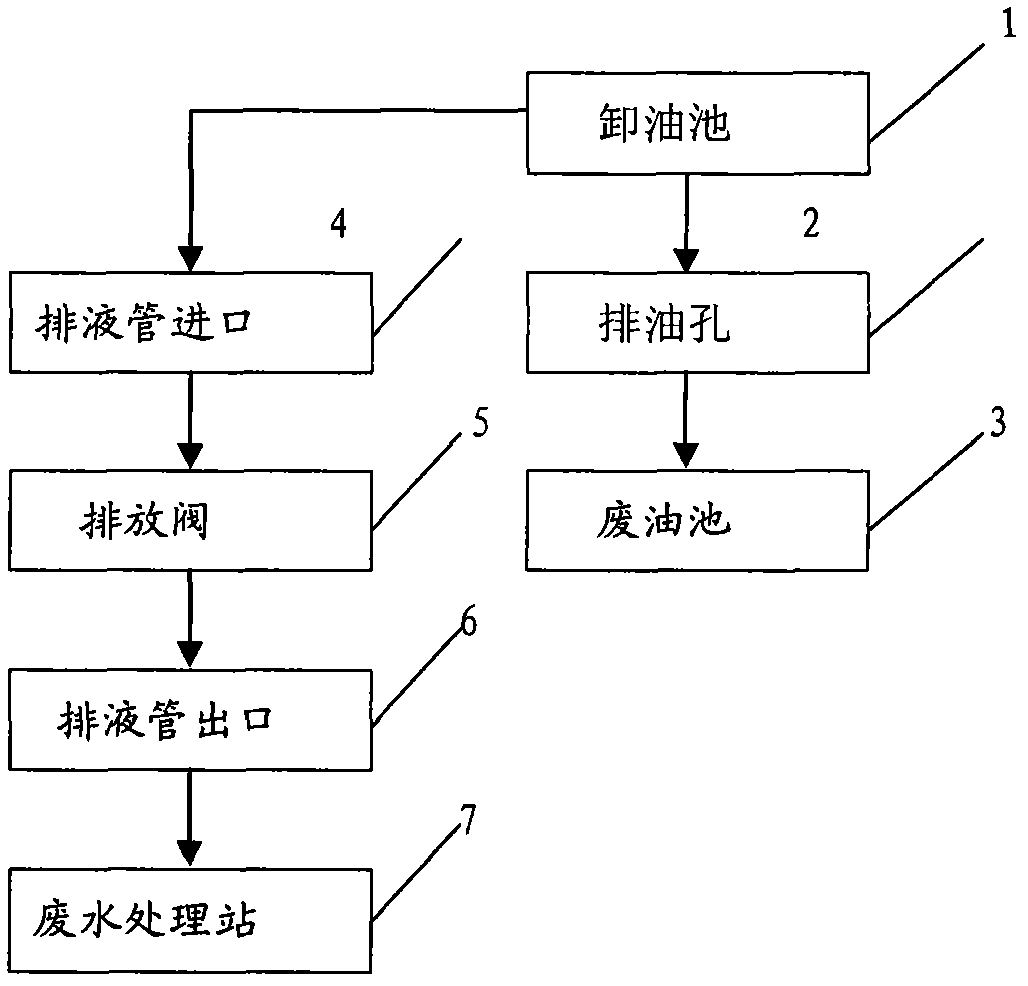

[0014] During the production process, the cold-rolling liquid is replaced after being used for a certain period of time, and the waste cold-rolling liquid is discharged into the oil unloading pool 1, and the waste cold-rolling liquid in the oil unloading pool 1 passes through the drain pipe inlet 4, the discharge valve 5 and The discharge pipe outlet 6 is discharged into the waste water treatment station 7. When the discharge valve 5 is opened, when the liquid level of the oil unloading pool 1 is higher than the discharge valve 5, the waste cold rolling liquid in the oil unloading pool 1 is automatically discharged into the waste water treatment station 7 under the action of gravity, without power. When the liquid level of the oil unloading pool 1 is lower than the discharge valve 5, the discharge stops, and the floating oil will not flow into the waste water treatment station 7. The liquid level height of the waste cold rolling liquid in the oil unloading pool 1 is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com