Ultrawide SEDDQ deep-drawing automobile sheet and production method thereof

An automotive sheet and wide-width technology, applied in the field of steel rolling, can solve the problems of uneven heating, deviation of furnace area, strip bending, etc., and achieve the effects of excellent mechanical performance indicators, reducing belt breakage and parking accidents, and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of ultra-wide SEDDQ grade deep-drawn automobile plate provided by the invention, its chemical composition weight percent is:

[0024] C: 0.0020-0.0035%; Si≤0.03%; Mn: 0.15-0.20%; P≤0.012%; S≤0.015%; For Fe and other trace elements.

[0025] C in IF steel is a solid solution strengthening element, and its contribution to the strength has a great influence. In view of the low strength of the ultra-wide SEDDQ grade deep-drawing automobile sheet, the thermal deformation resistance is low, resulting in unstable production status in the furnace, and it is necessary to avoid Excessive C content leads to deterioration of product formability. Therefore, the composition range of C is limited and strictly controlled between 0.0020-0.0035%. In the tempering machine process, the tension is optimized before and after the tempering machine and the setting of the working roll diameter of the tempering machine. Realize the small flat elongation of ultra-wide SEDDQ grade IF steel...

Embodiment 2

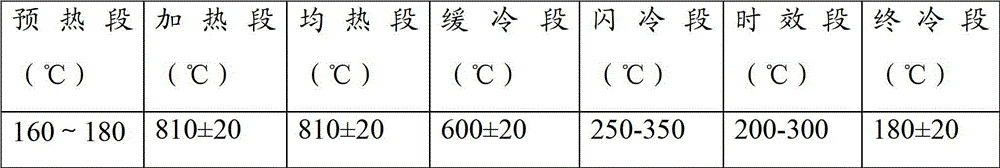

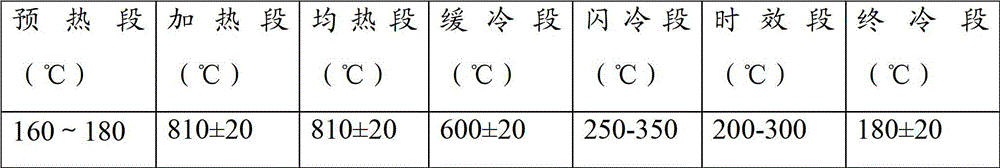

[0045] The difference between this example and Example 1 is that the mass percentage of the chemical composition of the slab is C: 0.0035%; Si: 0.005%; Mn: 0.20%; P: 0.002%; S: 0.0005%; Alt: 0.05% , N: 0.0010%, Ti: 0.07%, the balance is Fe and other trace elements. When heating the slab, the heating temperature was 1280°C. The finish rolling temperature of the hot-rolled sheet was 950°C. The coiling temperature was 720°C. When the hot-rolled coil is cold-rolled, the cold-rolling reduction rate is 84%. The thickness of the chilled roll is 0.8mm, and the flat elongation is 0.5%. The temperature of each section in the continuous annealing furnace is shown in Table 4:

[0046] Table four

[0047]

[0048] Other places are completely consistent with Embodiment 1.

Embodiment 3

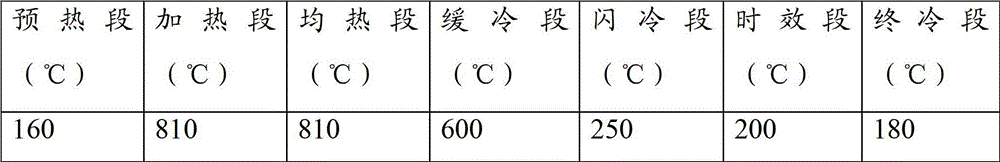

[0050] The difference between this example and Example 1 is that the mass percentage of the chemical composition of the slab is C: 0.0030%; Si: 0.0015%; Mn: 0.18%; P: 0.0002%; S: 0.0105%; Alt: 0.04% , N: 0.00010%, Ti: 0.06%, the balance is Fe and other trace elements. When heating the slab, the heating temperature was 1260°C. The finish rolling temperature of the hot-rolled sheet was 940°C. The coiling temperature was 740°C. When the hot-rolled coil is cold-rolled, the cold-rolling reduction rate is 83%. The thickness of the chilled roll is 1.0 mm, and the flat elongation is 0.6%. The temperature of each section in the continuous annealing furnace is shown in Table 5:

[0051] Table five

[0052] Preheating section

[0053] (℃)

[0054] Other places are completely consistent with Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com