Continuous splicing construction method of pier column for jacking broken beam of bridge

A construction method and technology for piers and columns, which are used in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of low strength, and the interface between post-cast concrete and old concrete is not dense, and can improve adhesion, compactness and adhesion. The effect of knot effect and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

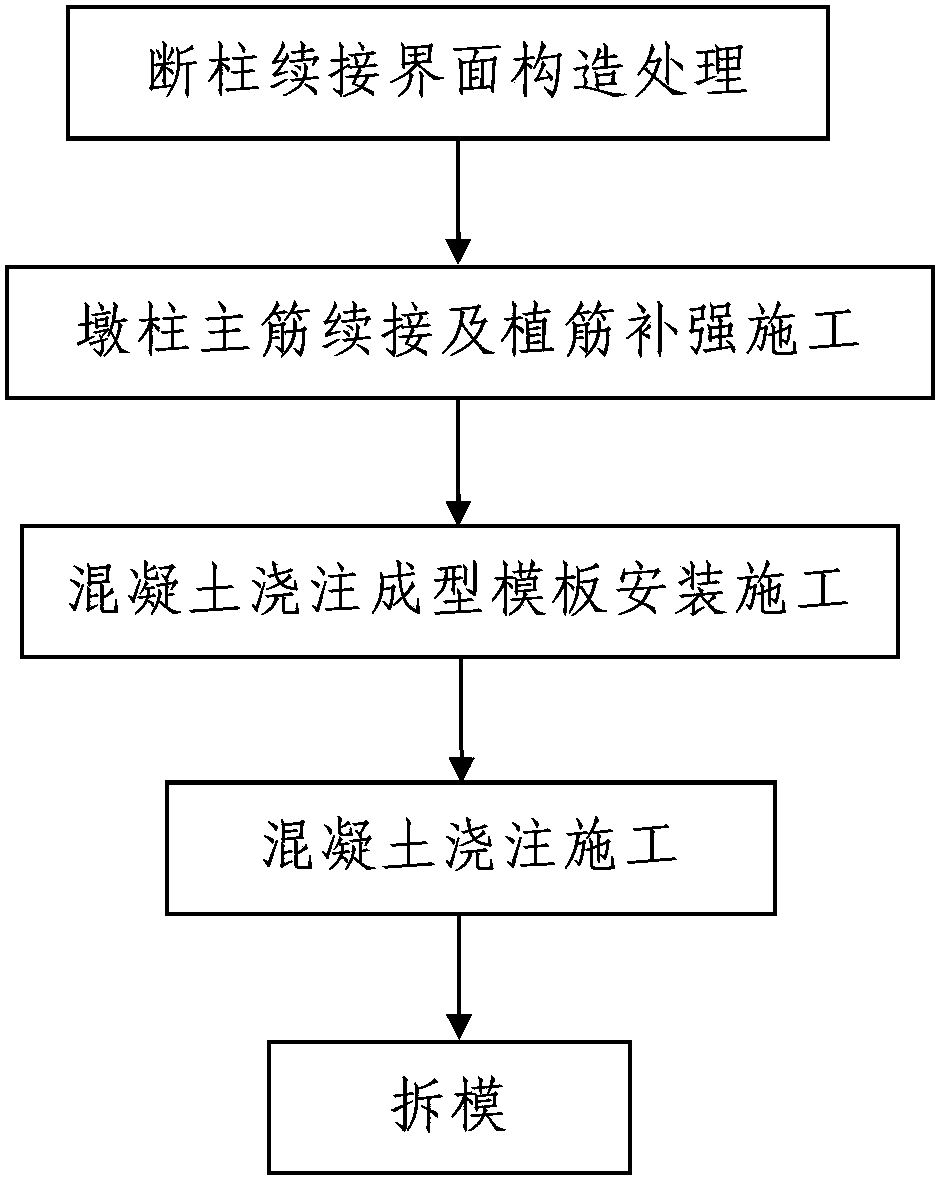

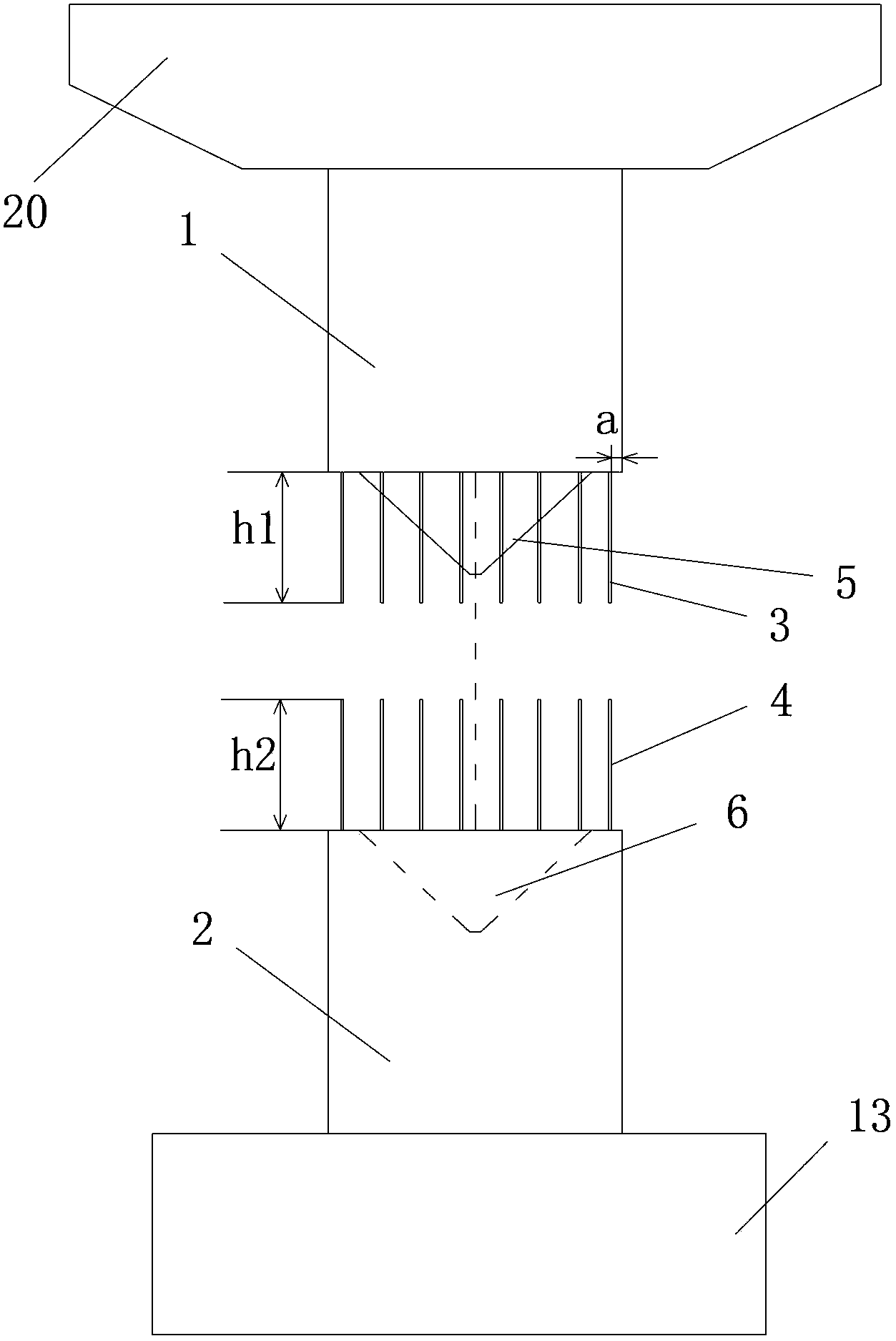

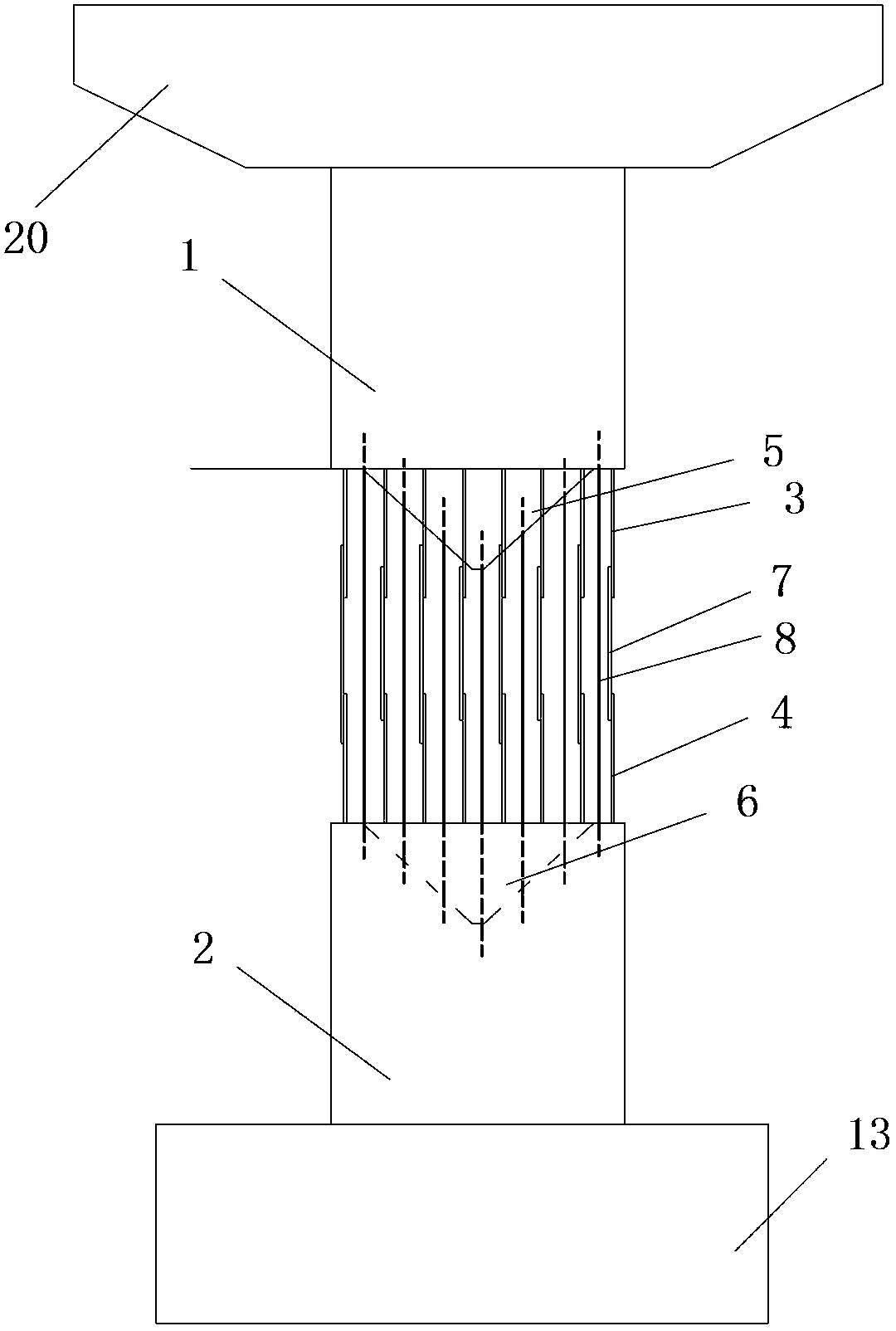

[0044] Such as figure 1 Shown is a bridge broken column jacking pier continuous connection construction method, the continuous pier column is the upper pier column 1 and the lower pier column 2, and the upper pier column 1 is the pier that has been cut and lifted into place column, the upper pier column 1 is located directly above the lower pier column 2 and the two are coaxially arranged, and the upper pier column 1 and the lower pier column 2 are both vertically arranged reinforced concrete structures; the upper pier column The pier column 1 is embedded with a plurality of vertically connected reinforcing bars 13, and the lower pier column 2 is embedded with a plurality of vertically connected reinforcing bars 24, and the plurality of vertically connected reinforcing bars 13 are respectively arranged on a plurality of Directly above the vertical connecting steel bar 2 4, a cover beam 20 is arranged directly above the upper pier column 1, see figure 2 . The bridge broken c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com