Highway guardrail with good energy absorption capacity

A highway, good technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of less kinetic energy, large dynamic shear force, vehicle damage, etc., and achieve the effect of preventing deformation and good viscoelastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

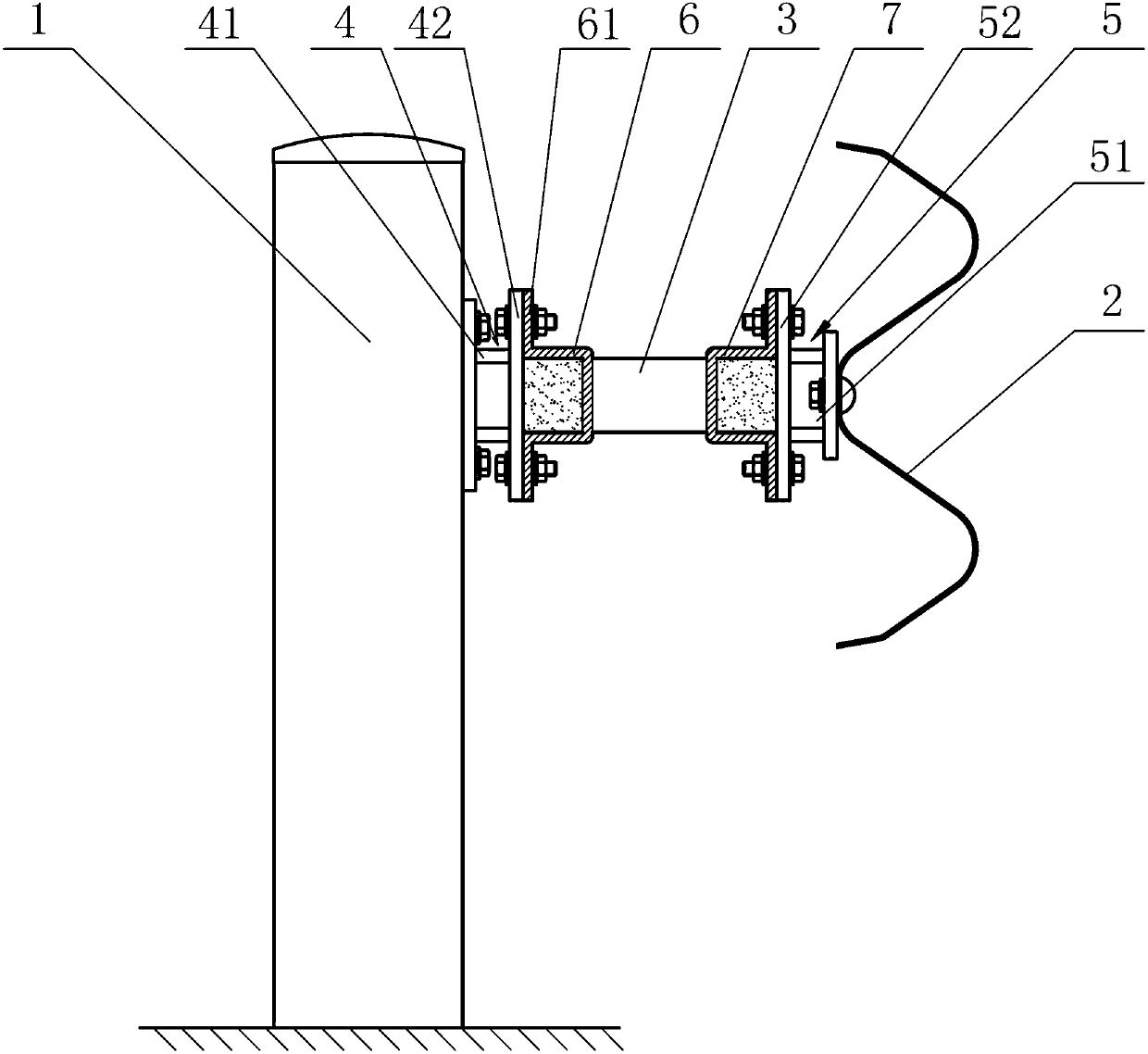

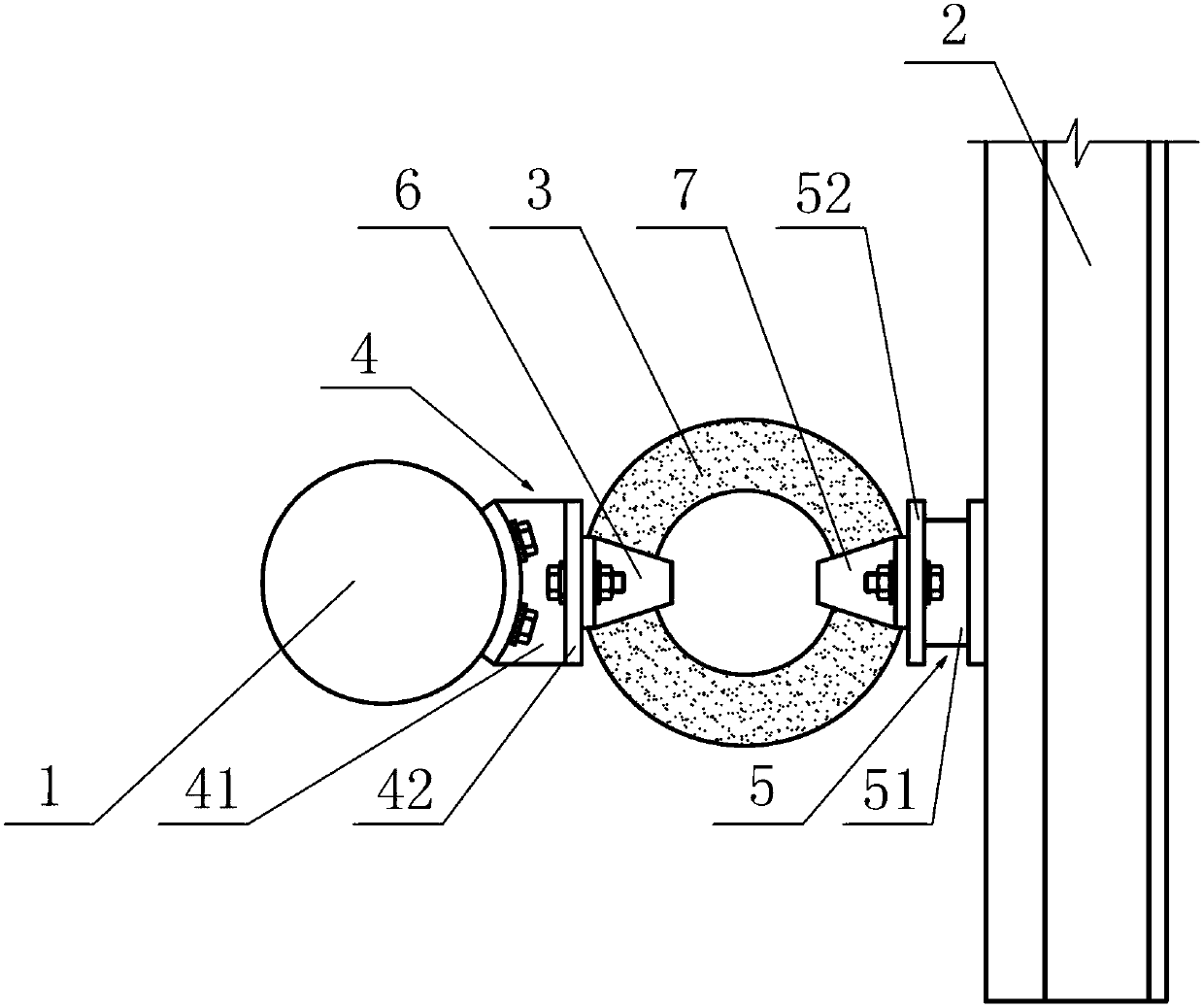

[0022] Embodiment one: if figure 1 , figure 2 As shown, a highway guardrail with good energy absorption performance includes a column 1 and a guardrail 2 arranged on one side of the column 1, a flexible anti-blocking block is fixed between the column 1 and the guardrail 2, and the flexible anti-blocking block 3 is an annular rubber ring 3 with a central hole, the column 1 is fixed with a first connecting block 4, the guardrail 3 is fixed with a second connecting block 5, and the annular rubber ring 3 is provided with a first set of The ring 6 and the second collar 7, the first collar 6 and the second collar 7 are arranged symmetrically along the center line of the annular rubber ring 3, and the annular rubber ring 3 is connected to the first connecting block through the first collar 6 4 is fixedly connected, and the annular rubber ring 3 is fixedly connected with the second connecting block 5 through the second collar 7 .

[0023] In this specific embodiment, the annular ru...

Embodiment 2

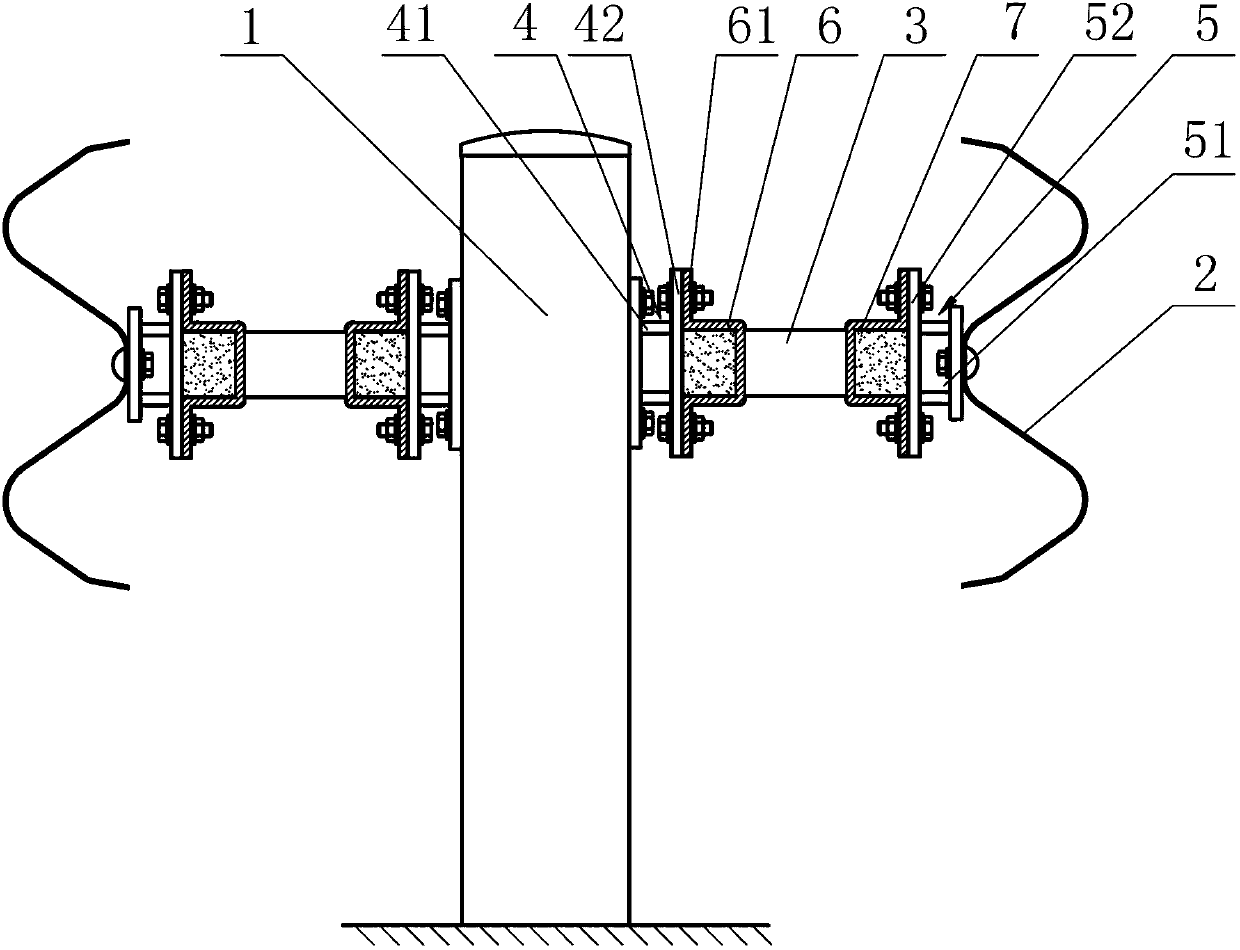

[0028] Embodiment two: other parts are identical with embodiment one, and its difference is that both sides of column 1 are all provided with guardrail board 2, as image 3 , Figure 4 shown.

Embodiment 3

[0029] Embodiment three: other parts are the same as embodiment one, and the difference is that the annular rubber ring 3 is vertically arranged, that is, the axial center line of the annular rubber ring 3 is parallel to the horizontal plane, as Figure 5 , Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com