Quick-exhaust type heavy hammer impact piling machine and quick-exhaust type piston impact piling machine

A piston impact and quick-displacement technology, which is applied to sheet pile walls, climate change adaptation, construction, etc., can solve the problems of increased weight, failure to seal the breach, and unsmooth exhaust of the lower chamber of the cylinder, so as to improve work efficiency , shorten the rescue time, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the drawings.

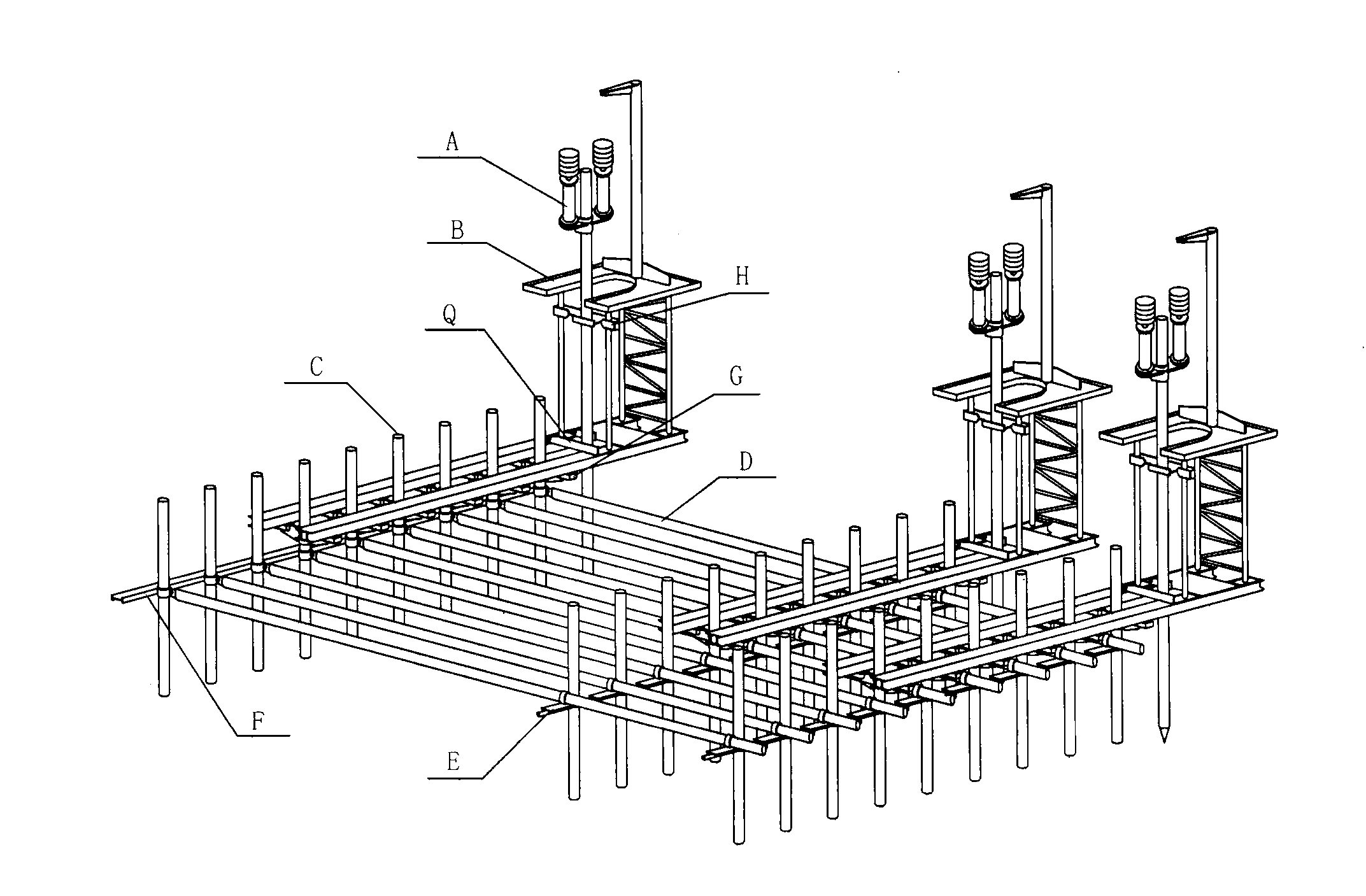

[0051] figure 1 It is a general schematic diagram of the device for blocking the dam breach. The figure shows the arrangement of the components in the device for blocking the dam breach. The composite steel pipe piles C are arranged upstream and downstream along the length of the fracture (the upstream is two rows and the downstream is one row). The upstream composite steel pipe piles C are connected by the upstream connecting rod E, and the downstream composite steel pipe The piles C are connected by a downstream connecting rod F, and the horizontal tie rod D fixes the upstream and downstream combined steel pipe piles C with the same cross section through the upstream connecting rod E and the downstream connecting rod F. The bracket G is installed above the upstream connecting rod E or the downstream connecting rod F, and the mobile platform B is installed on the upper edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com