Bridge pile-bucket combined foundation and construction method thereof

A technology combining foundation and construction method, applied in basic structure engineering, construction, etc., can solve the problems of inability to serve as a bridge foundation, insufficient vertical bearing capacity, large post-construction settlement, etc., achieve low requirements for construction machinery and equipment, reduce labor The effect of post settlement and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

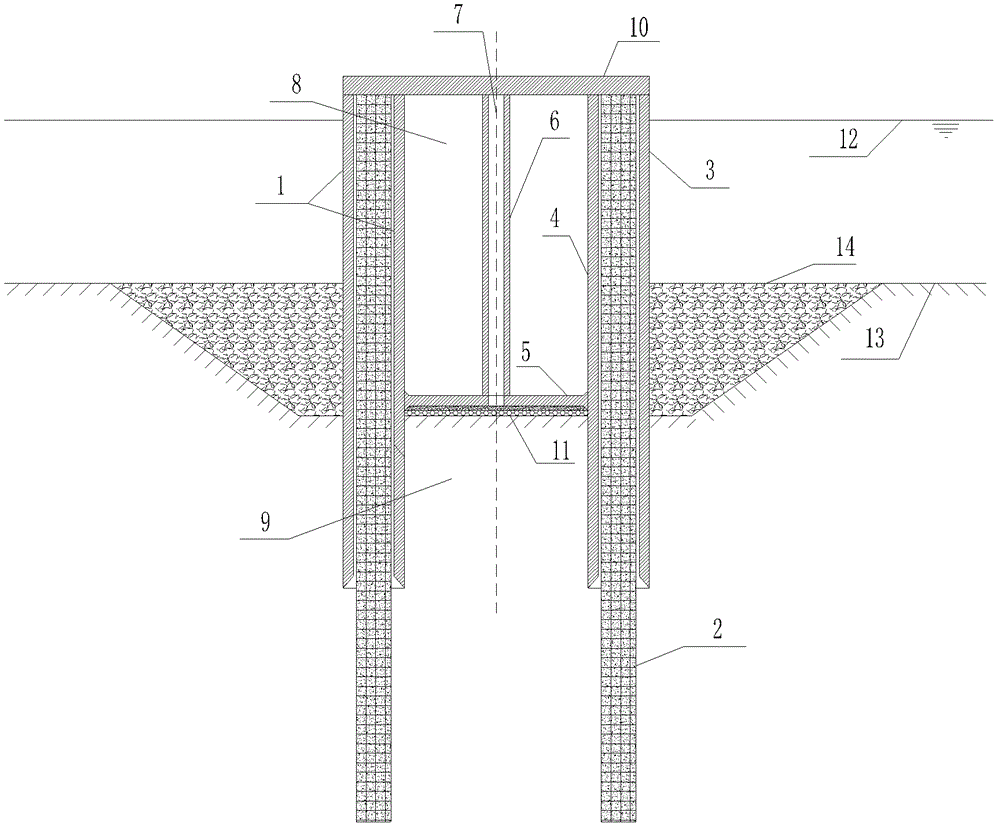

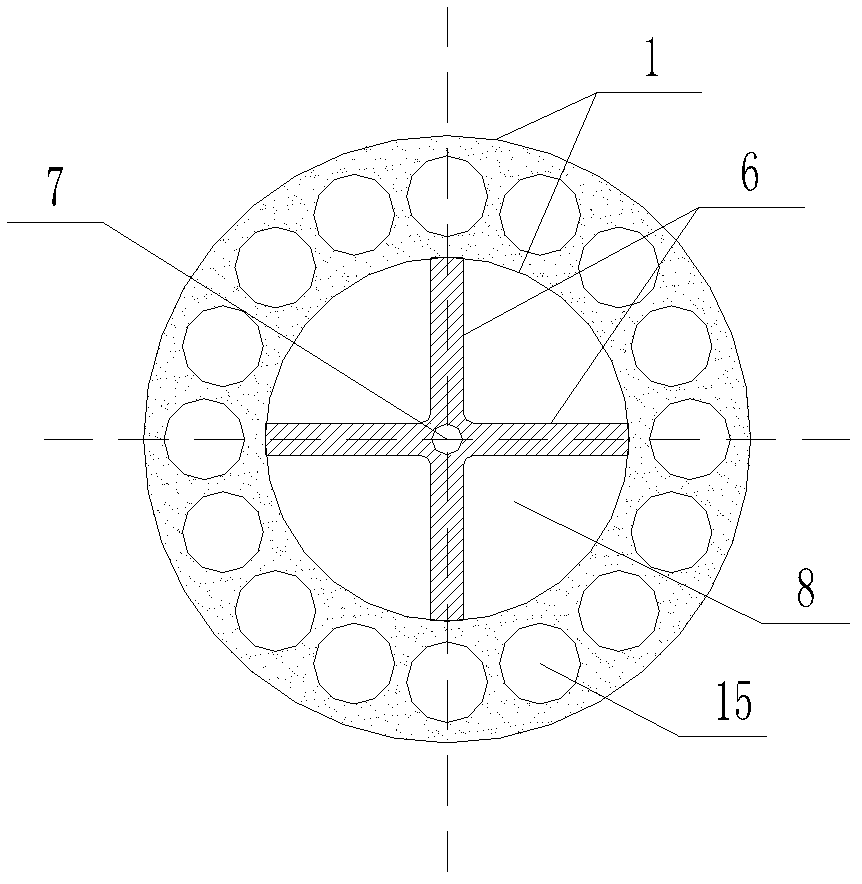

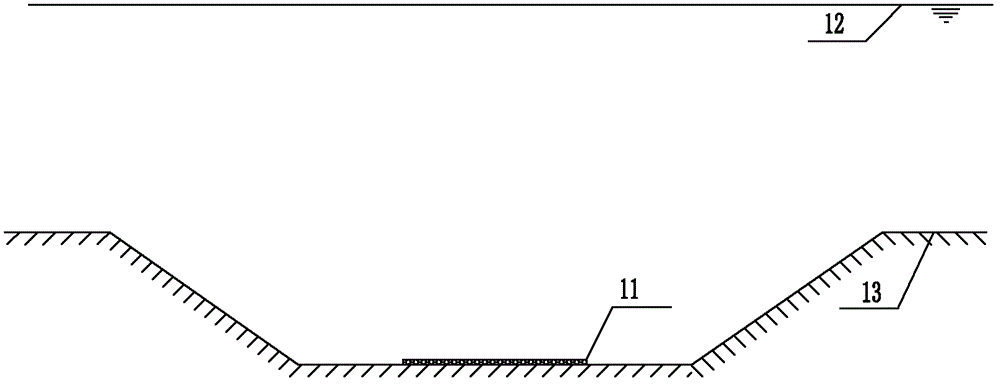

[0048] like figure 1 , 2 As shown, it is a schematic diagram of the combined foundation structure of bridge piles and barrels. The barrel body 1 is composed of the outer wall of the barrel 3, the inner wall of the barrel 4, the first partition 5, the second partition 6, the outer wall of the barrel 3 and the inner wall of the barrel 4. The foundation pile holes 15 are arranged vertically along the circumference.

[0049] The inner wall 4 of the barrel is provided with a first partition 5. The first partition 5 divides the inner cavity of the barrel into an upper cavity 8 and a lower cavity 9. The upper cavity 8 is provided with a second partition 6. This embodiment The middle and second partitions 6 have a cross structure, and the second partitions 6 divide the upper cavity 8 into four upper unit cavities (as shown in 2) that are spaced apart evenly. The second partition can also be of other structures, and the upper cavity 8 is evenly divided into five or six upper unit cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com