A Potential Imaging Method for Detecting the Integrity of High Polymer Cutoff Wall

A technology of anti-seepage wall and integrity, which is applied in the direction of basic structure test, construction, and basic structure engineering, etc. It can solve the problems such as the grouting effect of high polymer anti-seepage wall that has not been seen, and achieve intuitive and clear detection results. The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

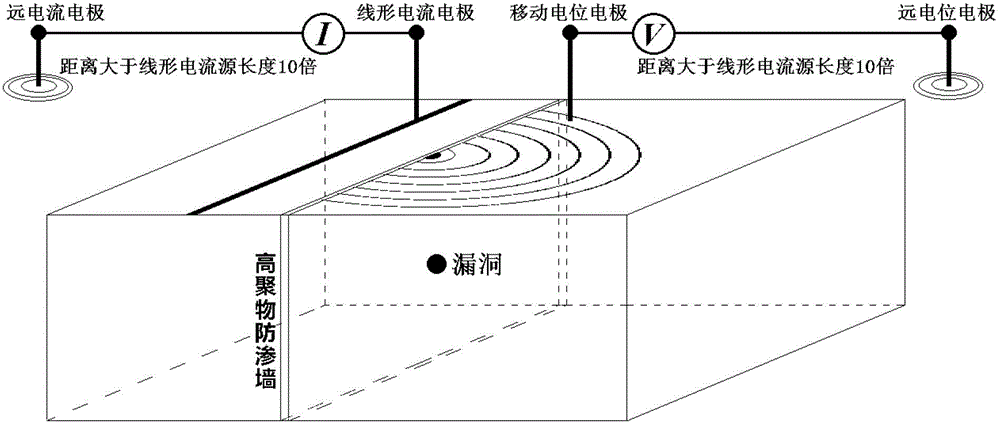

[0036] A potential mapping method for detecting the integrity of polymer cut-off walls, which is based on the physical property of high polymers to be electrically insulating, by emitting a current underground on one side of the cut-off wall and measuring the surface on the other side The potential (or potential difference) distribution of the potential (or potential difference), and the integrity of the underground cut-off wall can be obtained from the analysis of the potential distribution characteristics. It can be mainly used (but not limited to) to detect the integrity of polymer underground cut-off walls along structures such as reservoir dams, river dams and expressways.

[0037] Such as figure 1 As shown, the above method is applied to the detection of the integrity of the general underground cut-off wall, including the following steps:

[0038] Step 1: Set up a current emission system on one side of the anti-seepage wall. The current emission system includes a remote...

Embodiment 2

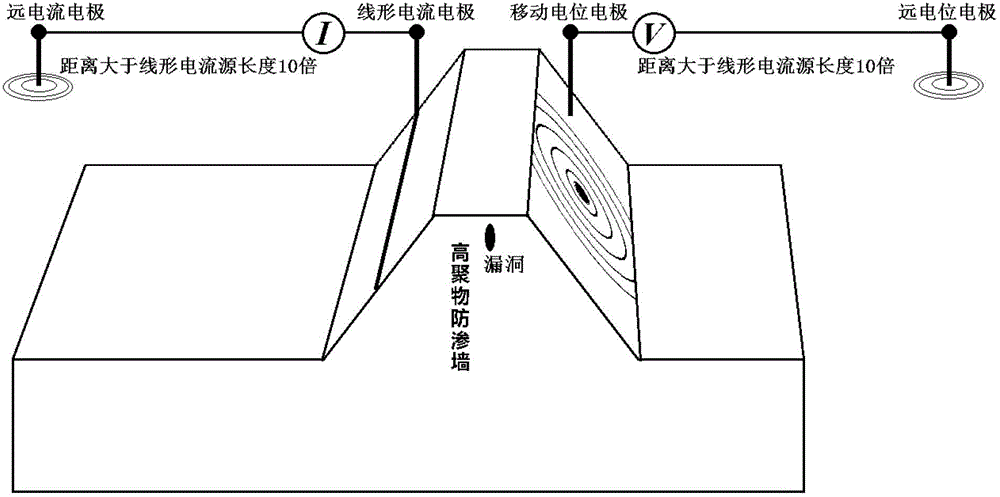

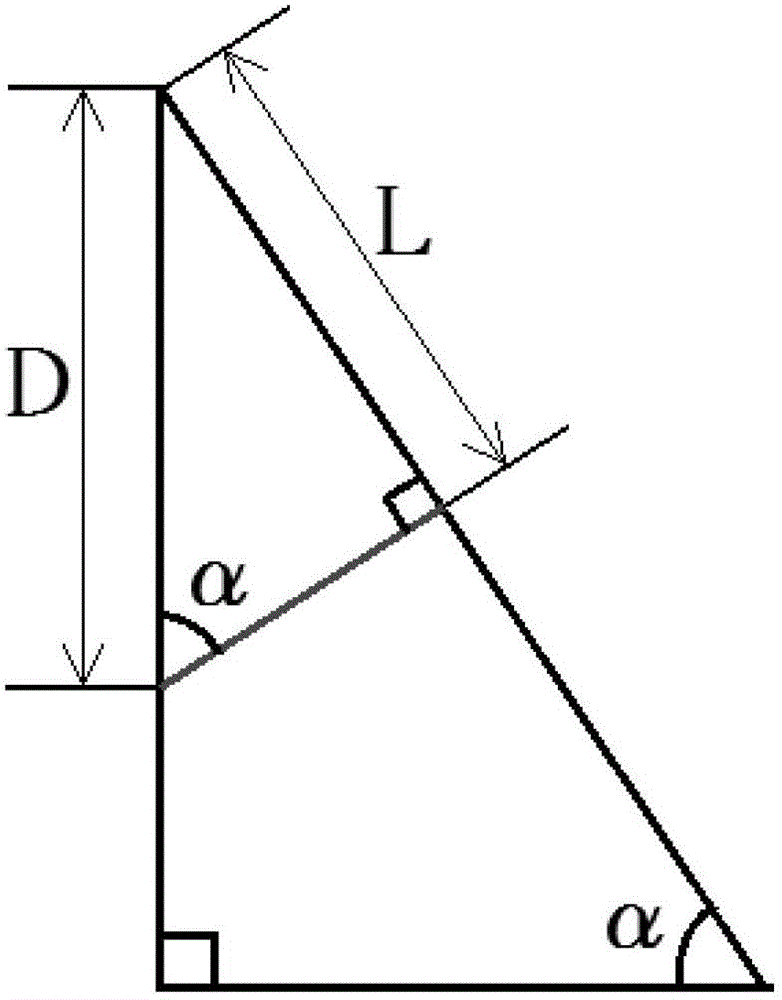

[0049] Such as figure 2 Shown is a schematic diagram of the principle of applying the potential imaging method for detecting the integrity of polymer cut-off walls to the detection of cut-off walls in embankments. This embodiment is basically the same as Embodiment 1. Such as image 3 As shown, in this embodiment, when the anti-seepage wall has a hole, the buried depth of the hole is calculated by the following formula:

[0050] Burial depth D = the oblique distance L / sin(α) from the extreme point of the equipotential line on the potential distribution diagram to the outcrop of the anti-seepage wall

[0051] sin(α) is the sine of the embankment slope angle α.

Embodiment 3

[0053] Such as Figure 5 As shown, in the potential mapping method for detecting the integrity of the polymer cut-off wall in this embodiment, the linear current source electrode is a plurality of electrodes connected by wires buried parallel to the axis of the cut-off wall, and the buried depth is about 0.3 meters. With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com