Mining stopping method for downwards mined underlying seams of coal seam group

A coal seam group, row type technology, applied in underground mining, surface mining, mining equipment and other directions, can solve the problems of roof easily detached layer, poor support quality, etc. Good promotion and application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for stopping mining of the lower coal seam in descending mining of a coal seam group according to the present invention comprises the steps of:

[0014] (1) When the coal wall of the working face is 30m to the stop line, start to adjust the working face, mine along the roof and floor of the coal seam, straighten and level the working face, make the slope of the working face consistent and control the mining height at 2.4-2.5 Meter;

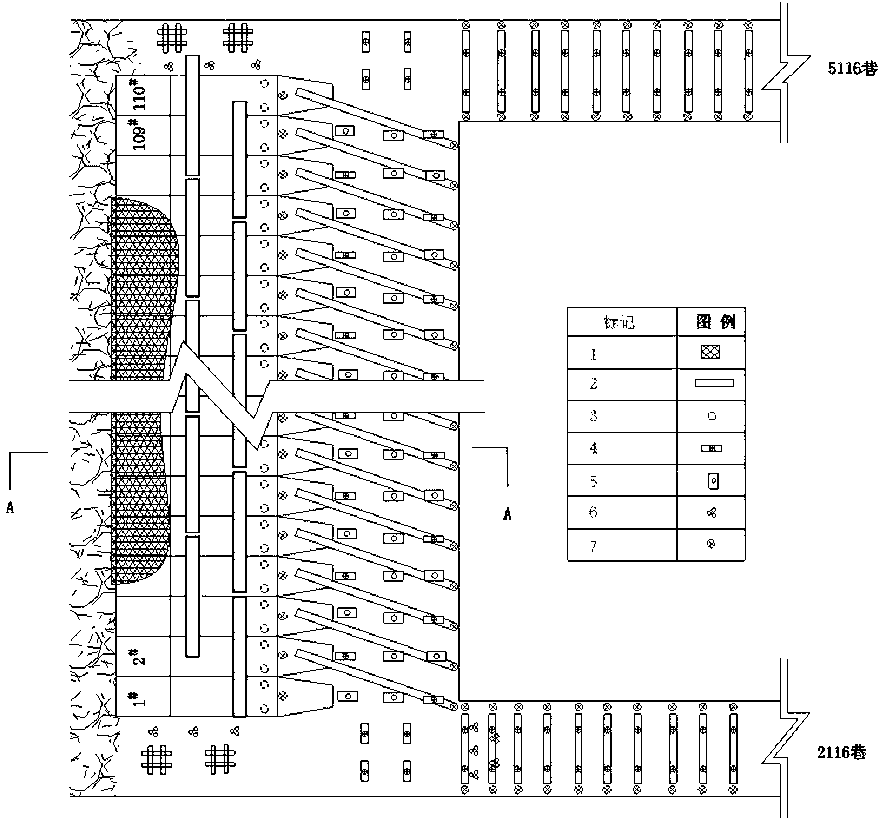

[0015] (2) Lay double-layer diamond-shaped metal mesh (1) within 11m of the working face from the stop line;

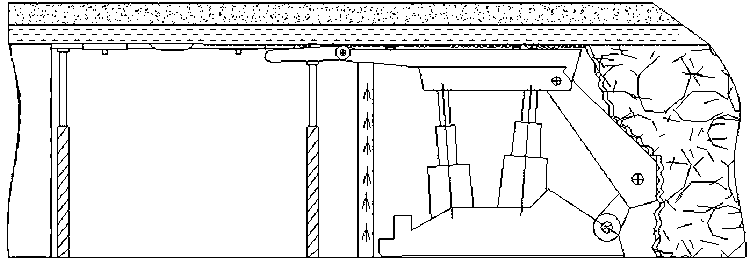

[0016] (3) Two rows of I-beams are used for the top plate of the main beam of the support after the working face is stopped. ; The roof of the machine way is supported by two rows of anchor cables (4) and three rows of anchor bolts (5) combined with inclined cantilever beams and hydraulic monomers.

[0017] The technical solution claimed in the present invention will be described in detail below by taking the coal seam g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com