Dual-mode automatic bearing lubricating device based on piezoelectric pump

An automatic lubrication and piezoelectric pump technology, which is applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve the problems of unreliable oil injection decision, low lubrication accuracy and resolution, complex structure, etc., to prevent bearing immersion The effect of excessive oil, simplified structure of the pumping device, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

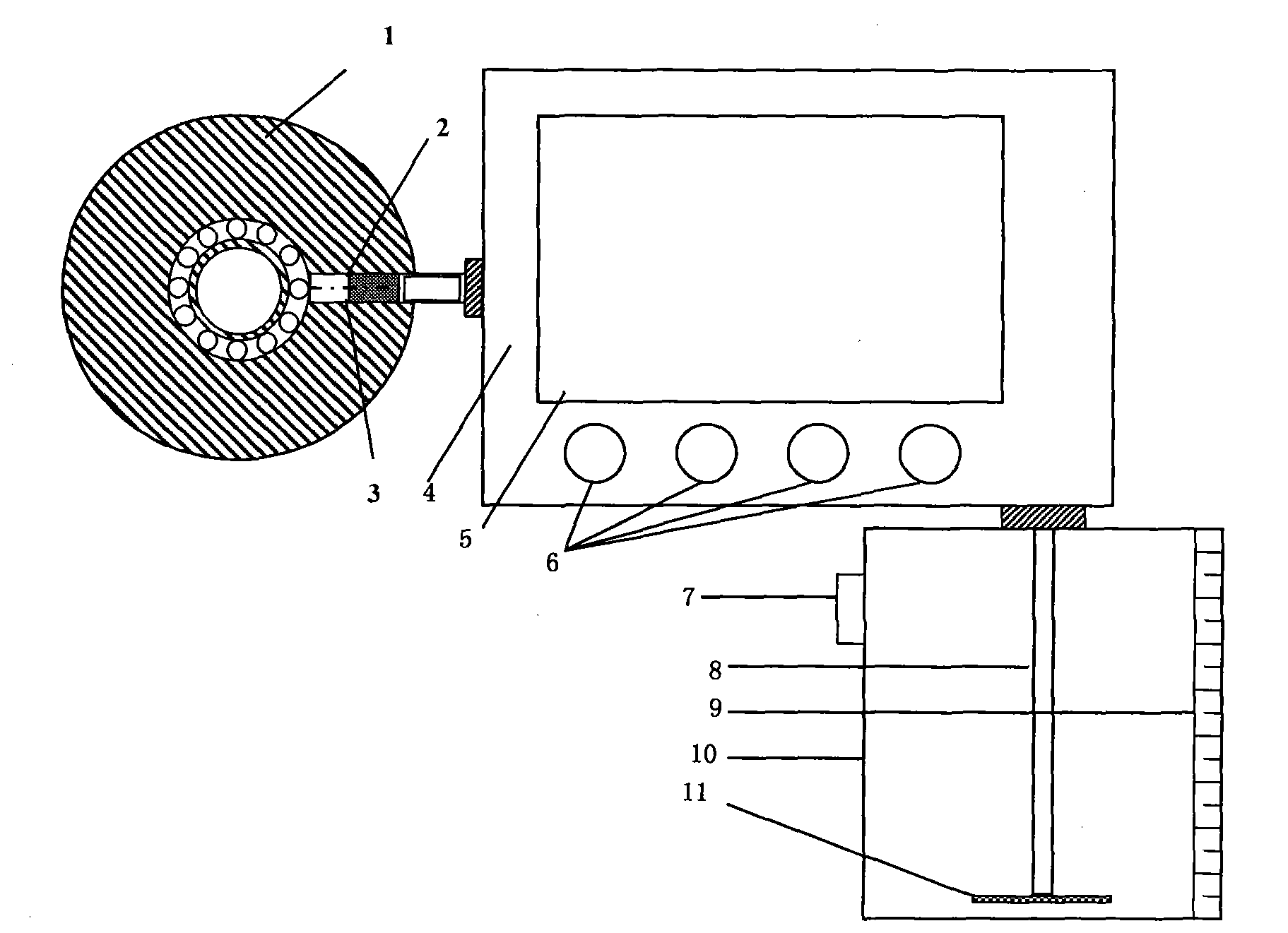

[0031] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

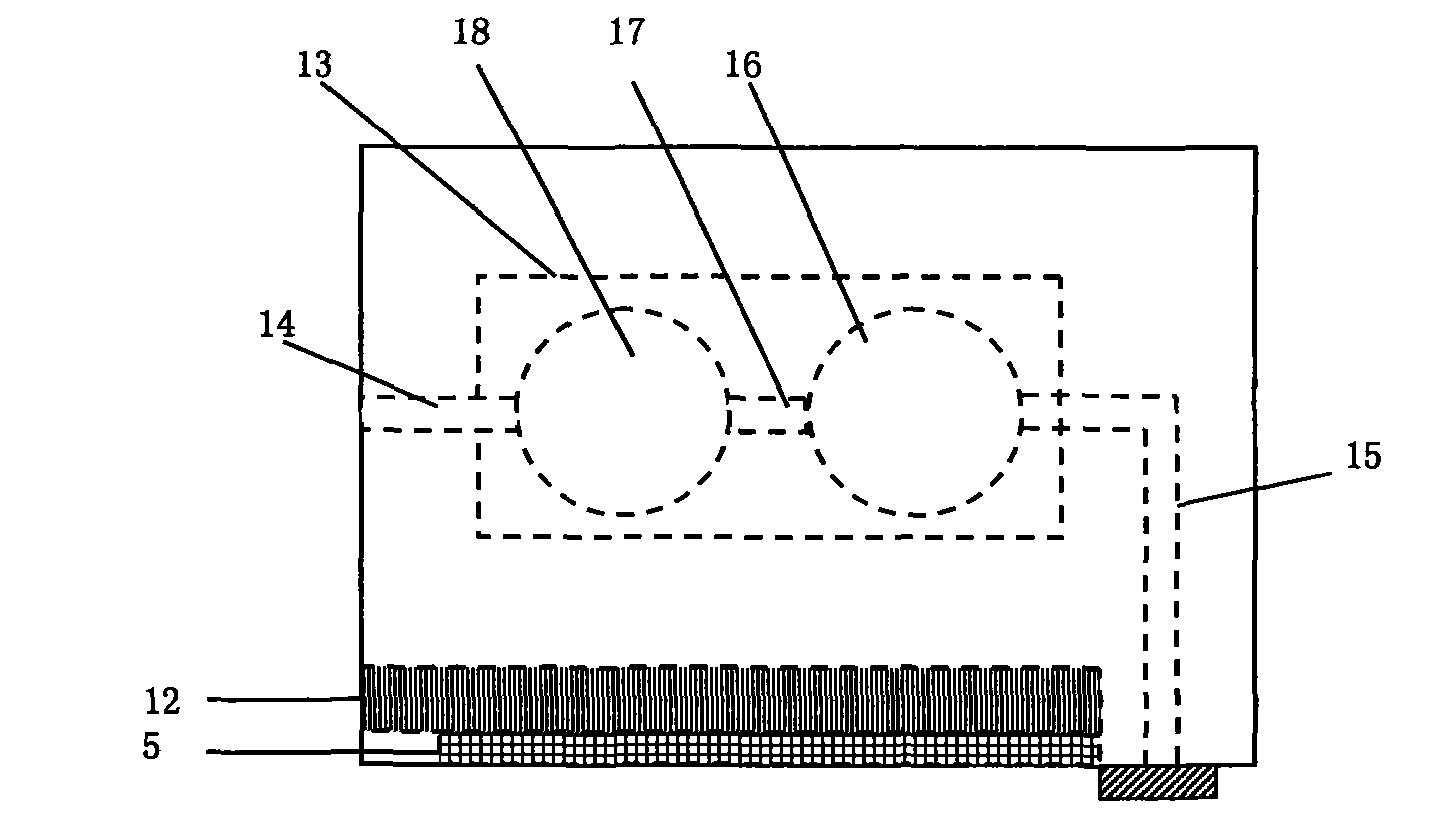

[0032] refer to figure 2 , the automatic lubricating device 4 has a man-machine interface self-setting lubricating work mode: (1). Manually set the lubricating operation time, injection amount and other information through the button 6, and display the operation process on the OLED display 5; (2). When When the sensors 2, 3 and another temperature sensor on the control circuit board 12 detect the information and evaluate that there is no overrun prompt, the whole set of lubricating device 4 implements drive control to the piezoelectric pump 13 according to the set information, and oils and lubricates; (3) .When the manual setting operation is not performed, the lubricating device 4 is filled with oil and lubricated according to the default information of the system.

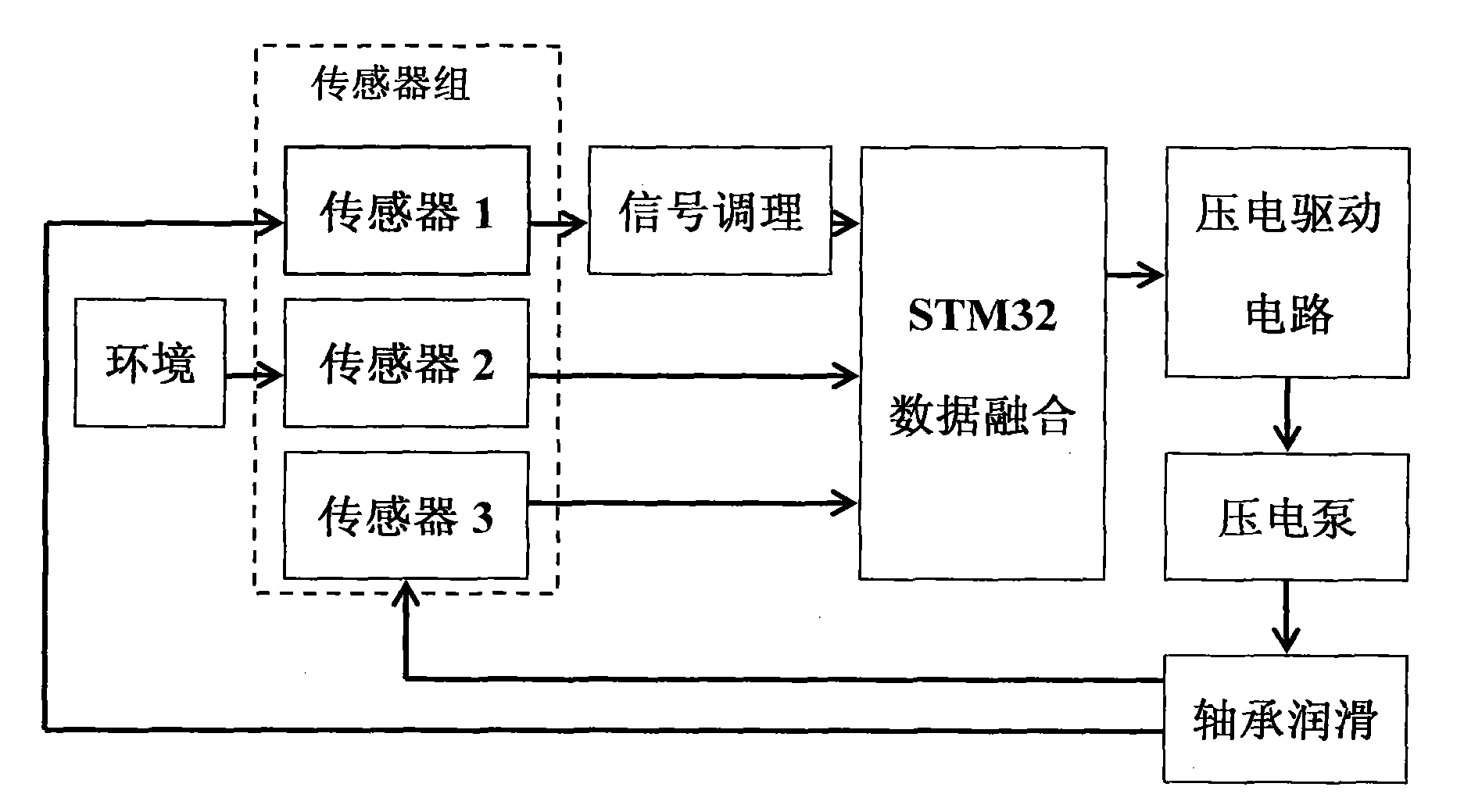

[0033] A lubrication working mode based on sensor data fusion process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com