Drying process of cleaning machine for cover plate glass

A technology of cover glass and drying process, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., which can solve the problems that the cleaning and drying process cannot be completely followed or not achieved, and achieves a remarkable drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Such as Figure 1~Figure 3 It is a specific embodiment of the present invention.

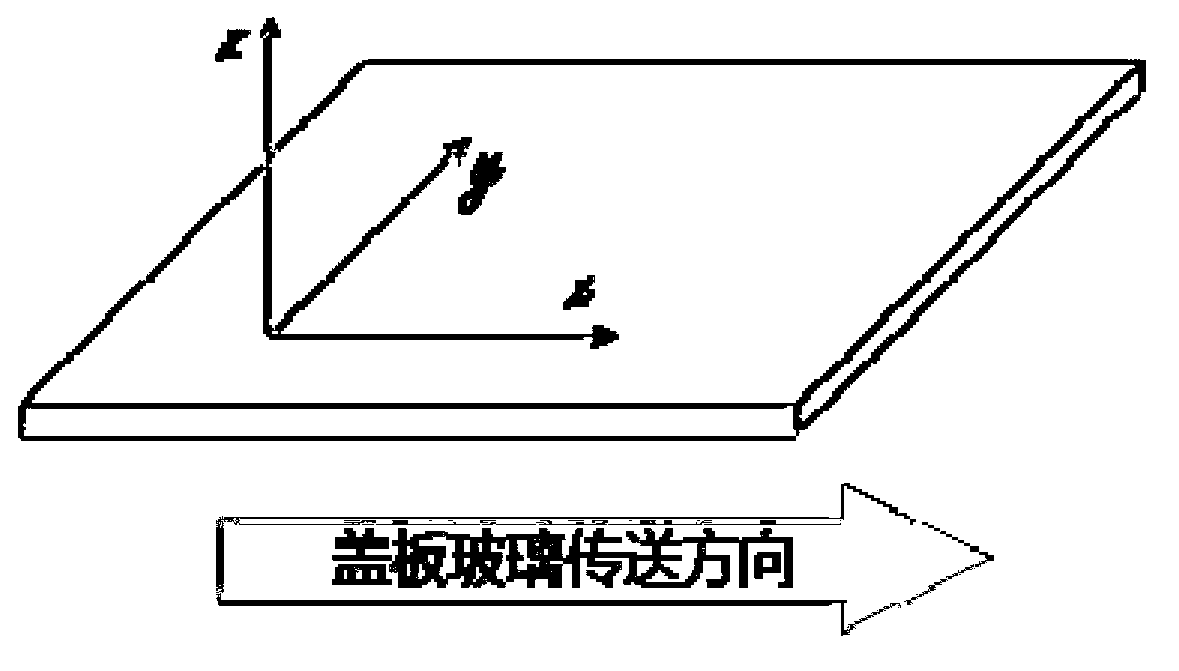

[0016] (1) Establish an x-y-z coordinate system: establish an x-y coordinate plane with the cover glass conveying plane as the reference plane, define the forward conveying direction of the glass as the x-axis, and define the conveying plane perpendicular to the conveying direction as the y-axis. At the same time, the z axis is defined as the vertical x-y coordinate plane up.

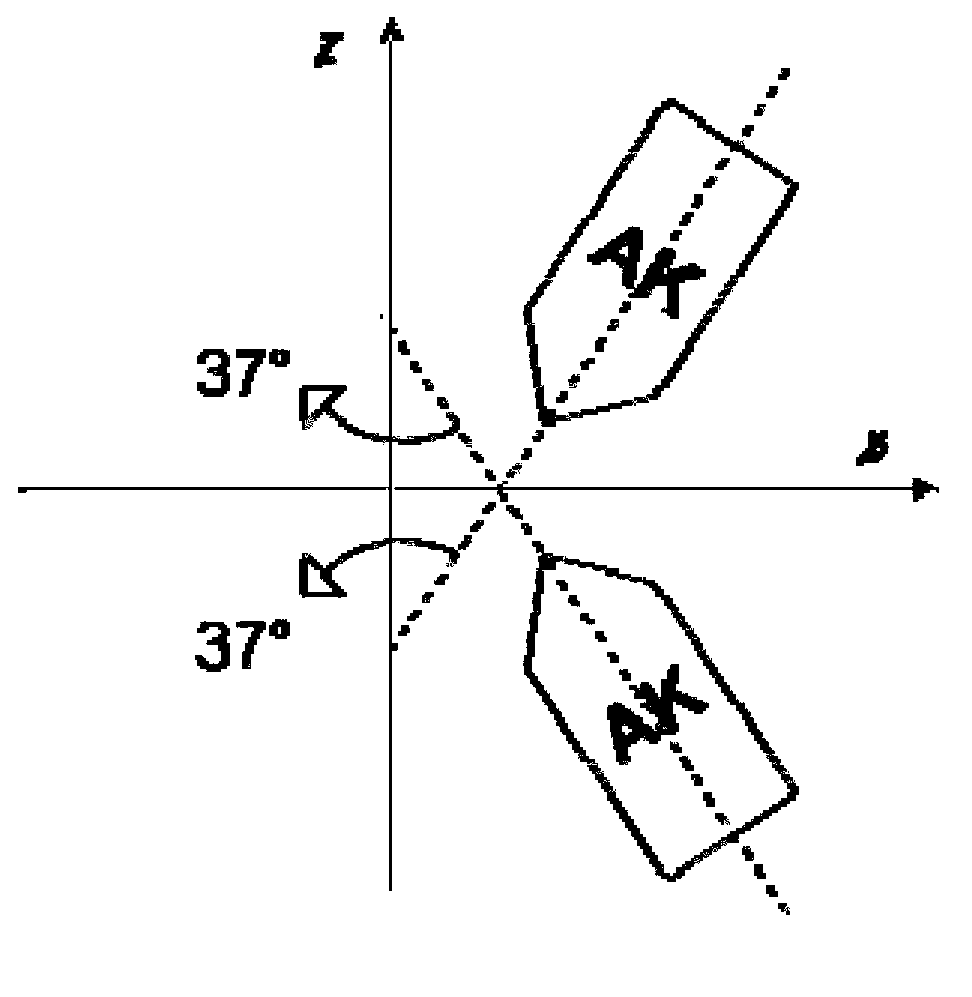

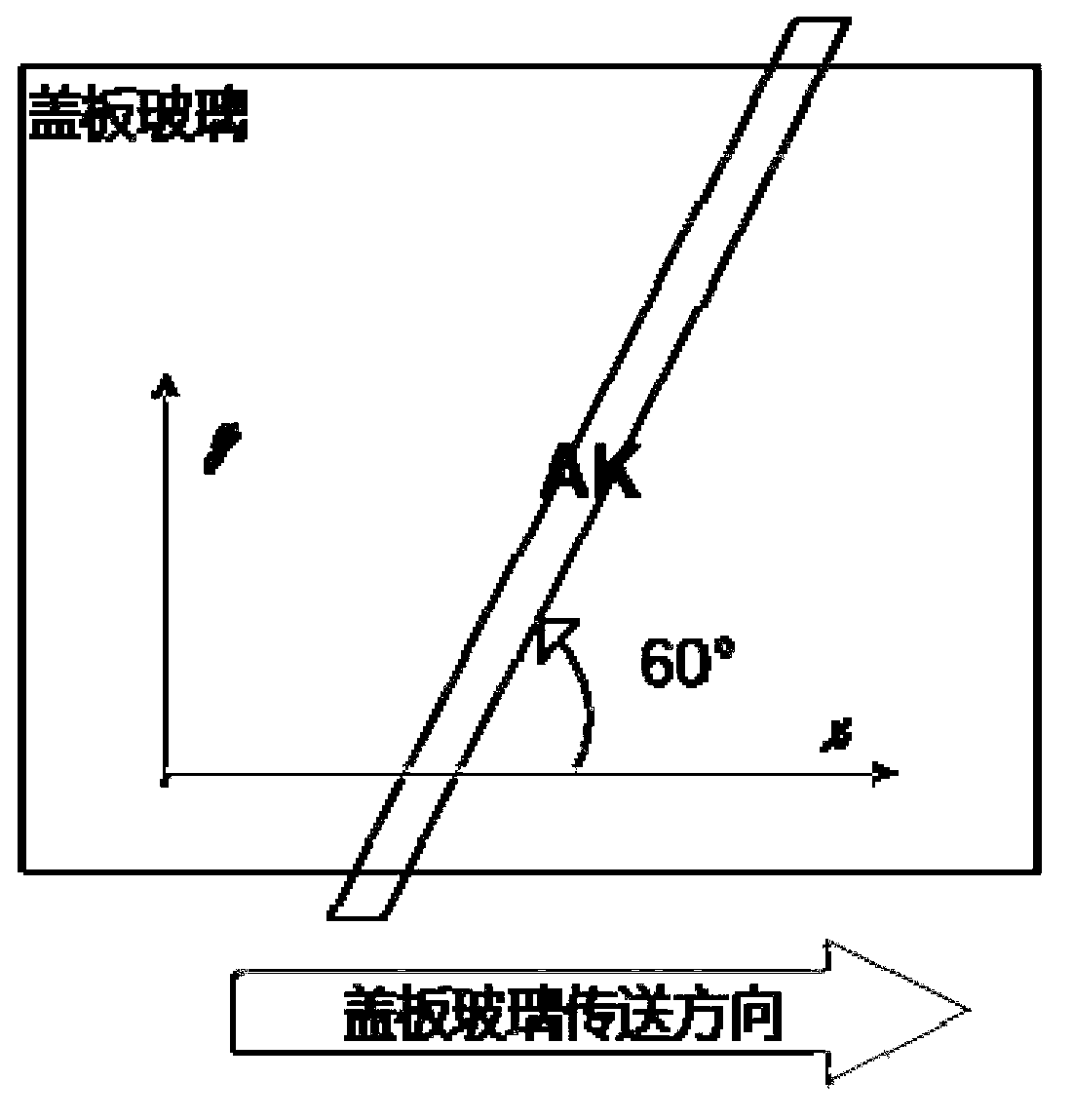

[0017] (2) The air outlet of the air knife AK is parallel to the x-y plane; it forms an included angle of 37° with the z-axis, that is, the inclination angle is 37°. On the x-y plane, the air knife needs to have an included angle of 60° with the x-axis, that is, the swing angle is 60°.

[0018] (3) The air knife is installed on the cleaning machine according to the installation angle of (2), and at the same time, the air outlet of the air knife (Air Knife) is 2mm away from the glass substrate, that is, Gap=2mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com