Novel structure of coal injection pipe head

A new type of structure, coal injection pipe technology, applied in furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of short service cycle, weathering and falling off of castables, and large maintenance, and achieve obvious wear resistance and impact resistance. The effect of reduced maintenance and high use value

Inactive Publication Date: 2013-04-03

SHANDONG LUZHU GRP

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The coal injection pipe head of the rotary kiln is exposed outside. After a long period of weathering and burning, the castable of the coal injection pipe head is often weathered and peeled off. The service life is short and the maintenance volume is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

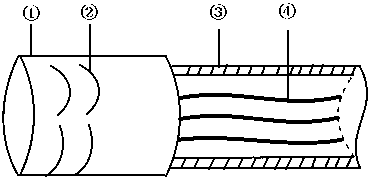

[0009] The pouring material at the front 1 of the coal injection pipe is thickened, and nails 2 are added to enhance the wind erosion resistance, and the inner pipe 3 at the back is added with a rib 4 structure to increase the strength. Through this structure, the frequency of maintenance can be effectively reduced, and it has the effect of high use value, wear resistance and impact resistance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a novel structure of a coal injection pipe head. The castable of the front head of a coal injection pipe is thickened, clasp nails are added, and a reinforcing rib structure is added in the inner pipe at the rear head, so that the strength and the wind erosion resistance of the coal injection pipe are increased, and the service quantity and the maintenance frequency are reduced. The use value is high, and the abrasion resistance and impact resistance effects are obvious.

Description

technical field [0001] The invention relates to a novel structure of a coal injection pipe head. Background technique [0002] The coal injection pipe head of the rotary kiln is exposed outside. After a long period of weathering and burning, the castable of the coal injection pipe head is often weathered and peeled off, resulting in a short service life and a large amount of maintenance. Contents of the invention [0003] In order to solve the above problems, the present invention provides a novel structure of a coal injection pipe head. [0004] The present invention is realized in the following way: the pouring material at the front of the coal injection pipe is thickened, and nails are added, and the inner pipe at the back is added with a reinforcing rib structure. [0005] The beneficial effects of the invention are: the strength and wind erosion resistance of the coal injection pipe are increased, the amount of maintenance and the frequency of maintenance are reduced...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27B7/20

Inventor 杨德果徐衍顺施成磊沈云彤桑胜敏

Owner SHANDONG LUZHU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com