Ultra-high-performance concrete decorating hanging board with self-cleaning photocatalysis function and manufacturing technology thereof

An ultra-high performance, decorative siding technology, applied in the field of architectural decoration, can solve the problems of poor weather resistance, UV resistance, peeling, insufficient durability, etc., and achieve high strength and weather resistance, and promote the effect of reaction efficiency and low water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

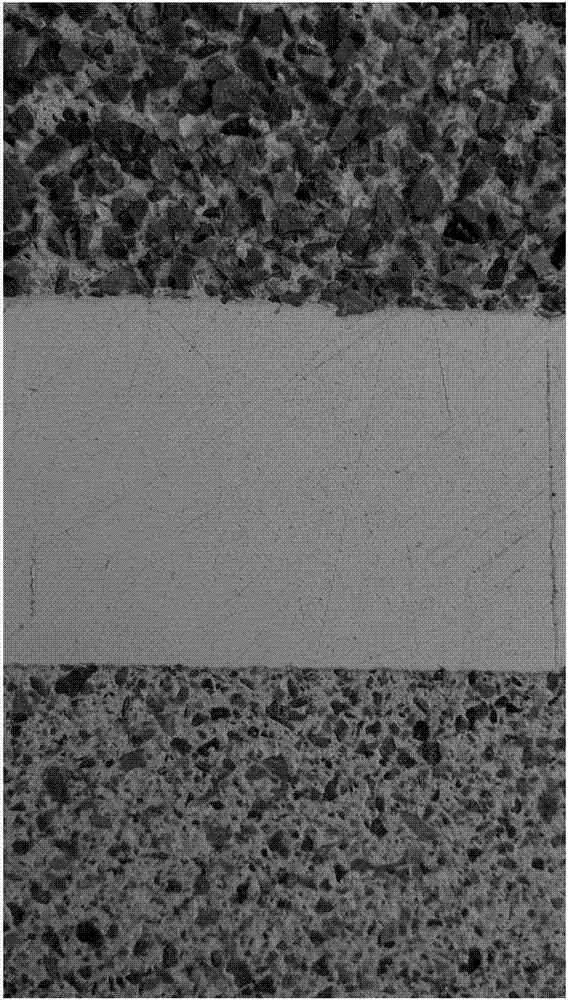

Image

Examples

Embodiment 1

[0027] The ultra-high-performance concrete decorative hanging board with high-efficiency self-cleaning photocatalytic function is prepared by the process of the following steps:

[0028] 1. Use PVC wood-plastic formwork to make the mold, and clean the dust on the surface of the mold;

[0029] 2. Apply solvent-based surface retarder on the surface of the mold, the model is RECKLI CR TYPE N / 02, and the dosage is 200g / m 2 , enter the next process after the surface is dry;

[0030] 3. Put the UHPC dry mixture into the mixer and add water (UHPC is a commonly used UHPC material in the market, its compressive strength is 100-150MPa, and the maximum particle size of its aggregate is not more than 1mm, the same below) and stir until the slurry becomes fluid , add glass fiber in an amount of 0.7% of the volume of UHPC, and stir evenly;

[0031] 4. Pour the stirred UHPC material into the mold, and pave and smooth the surface;

[0032] 5. Maintain the UHPC until the compressive strengt...

Embodiment 2

[0037] The ultra-high-performance concrete decorative hanging board with high-efficiency self-cleaning photocatalytic function is prepared by the process of the following steps:

[0038] 1. Use steel formwork to make the mold, and clean the dust on the surface of the mold;

[0039] 2. Spray a solvent-based surface retarder on the surface of the mold, the model is RECKLI CR TYPE N / 02, and the dosage is 200g / m 2 , enter the next process after the surface is dry;

[0040] 3. Put the UHPC dry mixture into the mixer and add water to stir. After the slurry becomes fluid, add basalt fiber in an amount of 1.3% of the volume of UHPC, and stir evenly;

[0041] 4. Pour the stirred UHPC material into the mold, and pave and smooth the surface;

[0042] 5. Maintain the UHPC until the compressive strength reaches 48MPa before demoulding, and rinse the mold surface of the UHPC board with a high-pressure water gun, and rinse off the cement paste that has contacted the retarder on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com