Antibacterial deodorization two-side coating polyester aluminized film and production method thereof

A technology of polyester aluminum plating and film, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc. and other problems, to achieve the effect of high practical value, beneficial to human health, and increased compound fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

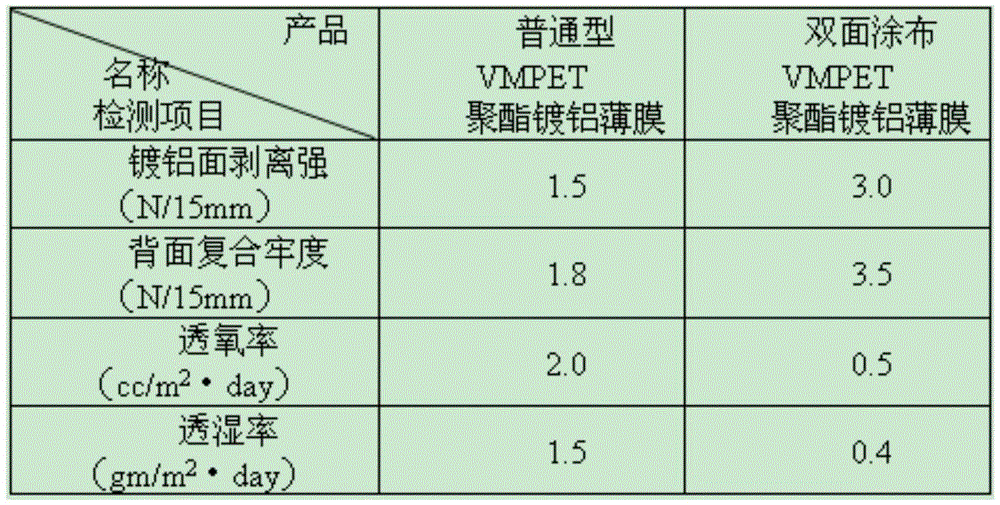

[0012] An antibacterial and deodorizing double-coated polyester aluminized film is prepared from a polyester base material through double-sided coating, wherein one side is coated with a PMMA composite coating, and the other side is coated with a polyurethane composite coating, wherein the PMMA composite coating is formed from the bottom The raw materials in parts by weight are made of: PMMA emulsion 40, water-based polyurethane emulsion 5, silica sol 10, polyvinyl alcohol 0.5, silane coupling agent KH-5500.3, Tween-800.1, water 40;

[0013] The preparation method of PMMA composite coating is to add polyvinyl alcohol, Tween-80 and silane coupling agent KH-550 together to water at 85°C and stir for 2h, then adjust the temperature to 40°C, and then add the remaining raw materials at 1000r / min and stir for 10min. That is, composite PMMA coating is obtained;

[0014] The polyurethane composite coating is made from the following raw materials in parts by weight: water-based polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com