High-corrosion-resistance plate material and processing method thereof

A technology with high corrosion resistance and processing methods, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of easy corrosion, reduced plate life, poor flame retardancy, etc., to increase corrosion resistance and abrasion resistance, improved weather resistance and strength, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

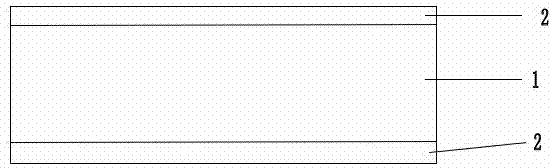

[0014] figure 1 Among them, a high-corrosion-resistant plate, which includes a plate substrate 1, the plate substrate 1 is mainly composed of: PVC (polyvinyl chloride), whiskers, titanium dioxide, calcium carbonate, and stabilizers. The ratio of various components For: 200 parts of PVC, 20-40 parts of whiskers, 16-20 parts of titanium dioxide, 6-10 parts of calcium carbonate, 16-20 parts of stabilizer, the surface of the board substrate 1 is covered with SMC co-extrusion layer 2, SMC co-extruded Extruded layer 2 is applied to the exposed part of the surface of the board.

[0015] A processing method for high-corrosion-resistant plates: adding polyvinyl chloride, whiskers and various additives into a high-speed mixer, mixing and stirring evenly; putting the mixed raw materials into an extruder for high-temperature plasticization, The temperature is controlled within the range of 180°C-220°C; the extruded material is co-extruded with SMC into various shapes of plates through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com