Quick static twisting detection device of constant speed universal joint driving shaft friction welding piece

A constant velocity universal joint and detection device technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that affect the accuracy and reliability of the detection data, the time deviation of the torque output point, and the misjudgment of product processing quality. , to achieve the effects of simple line design layout, increased authenticity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

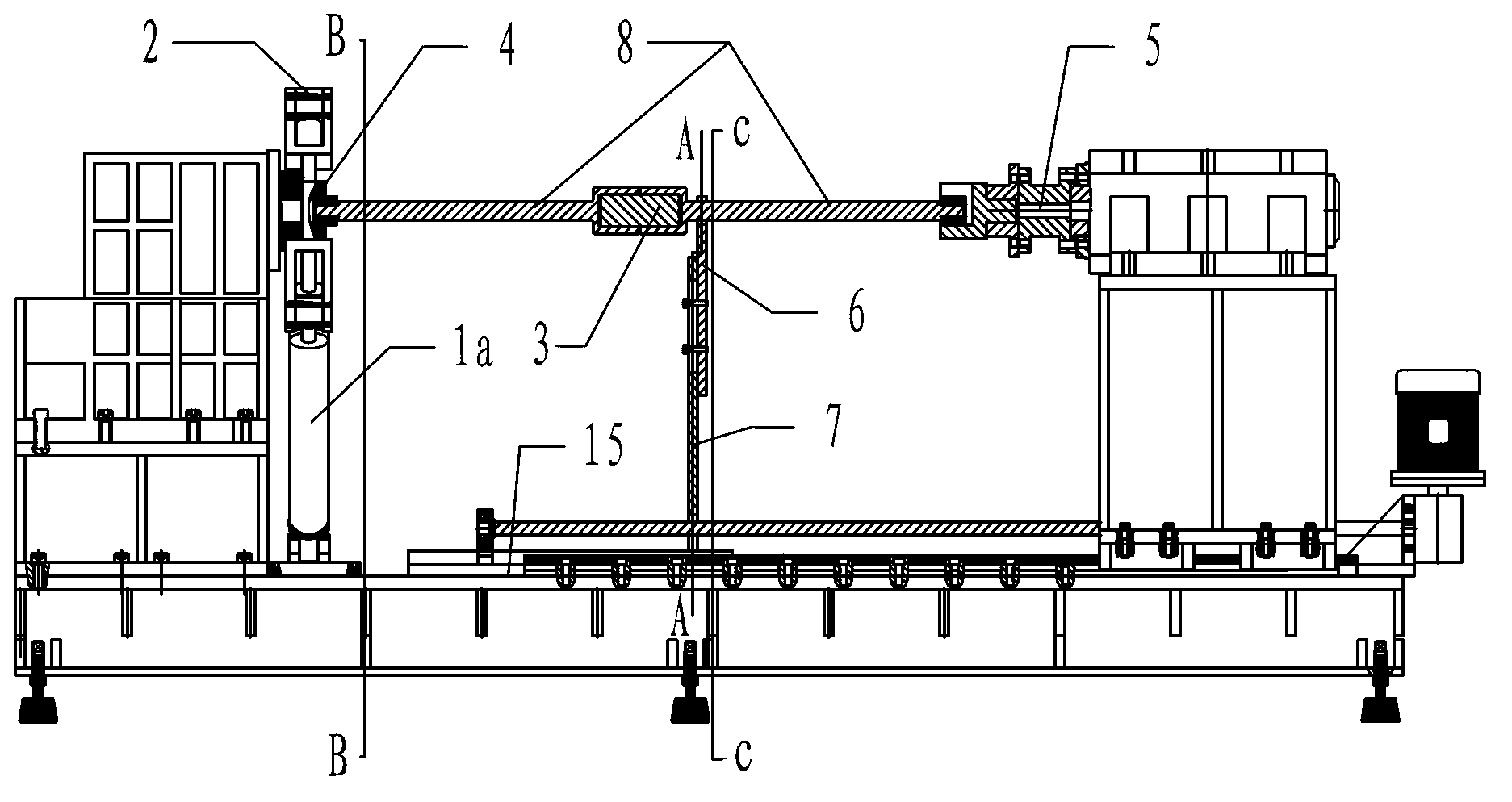

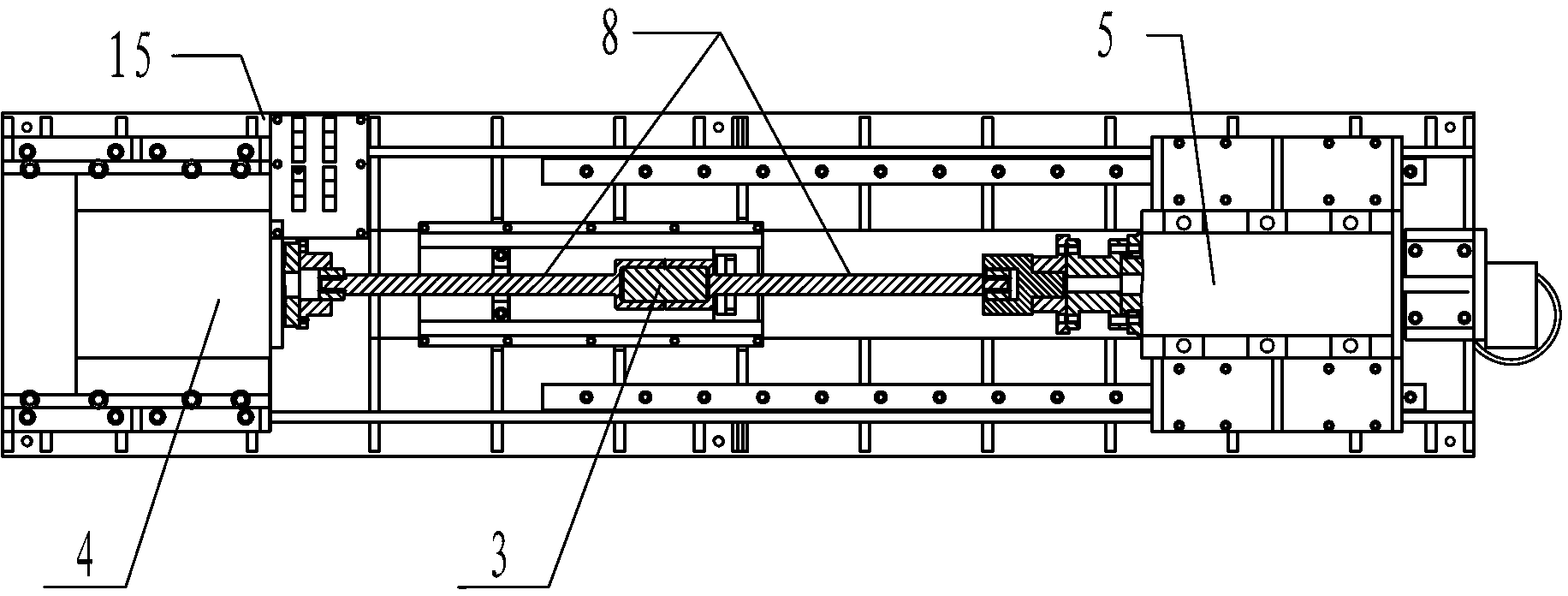

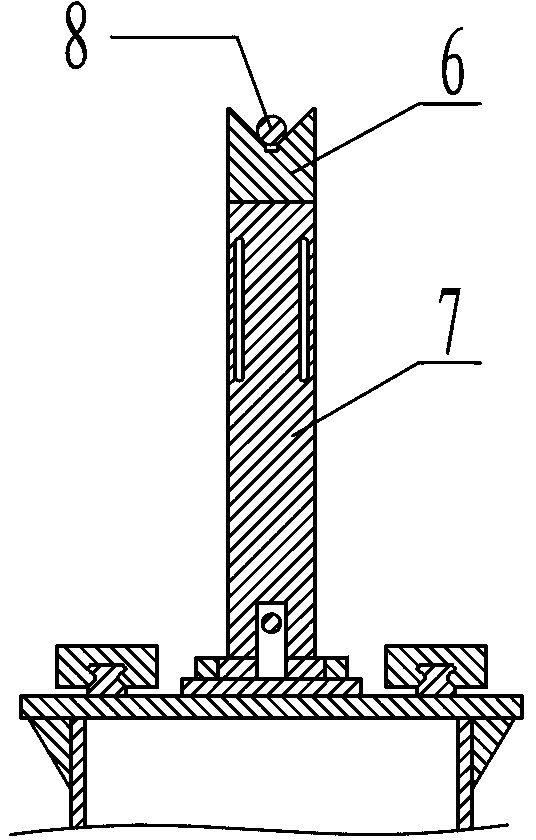

[0030] like Figures 1 to 7 As shown, the constant velocity universal joint drive shaft friction weldment rapid static torsion detection device includes a transmission system that is positioned on the body 15 and twists the workpiece 8 to be detected and a power system that drives the transmission system to rotate. A rocker arm 2 is provided, and the rotation of the rocker arm 2 drives the transmission system to rotate so as to realize the twisting of the detected workpiece 8. The power system is connected to the rocker arm 2 and drives the transmission system to rotate by driving the rocker arm 2 to rotate. The power The system includes a hydraulic cylinder I1a connecting the body 15 and one end of the rocker arm 2 and a hydraulic cylinder II1b connecting the body 15 and the other end of the rocker arm 2. Both the hydraulic cylinder I1a and the hydraulic cylinder II1b work through the hydraulic control system 21. The body 15 is equipped with There is a data acquisition and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com