Couple corrosion sensor

A technology of corrosion sensors and galvanic couples, applied in the direction of material electrochemical variables, etc., can solve problems such as changes in cathode reaction conditions, corrosion of metal materials, and influence on the accuracy of corrosion monitoring, and achieve the effect of enhancing effectiveness and monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

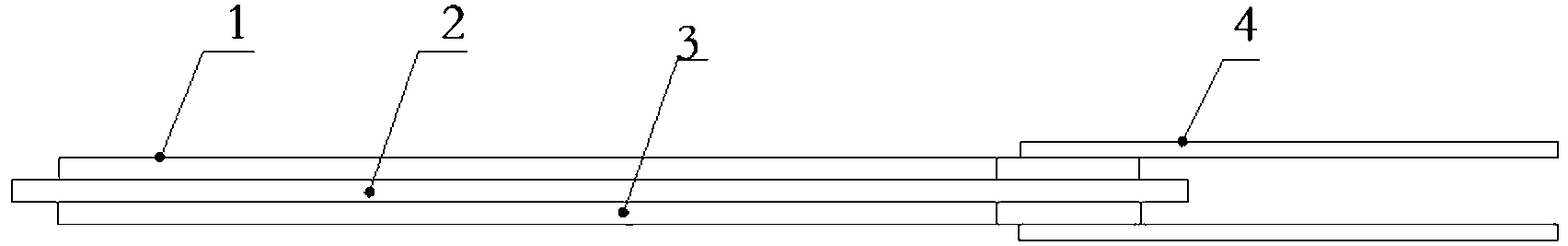

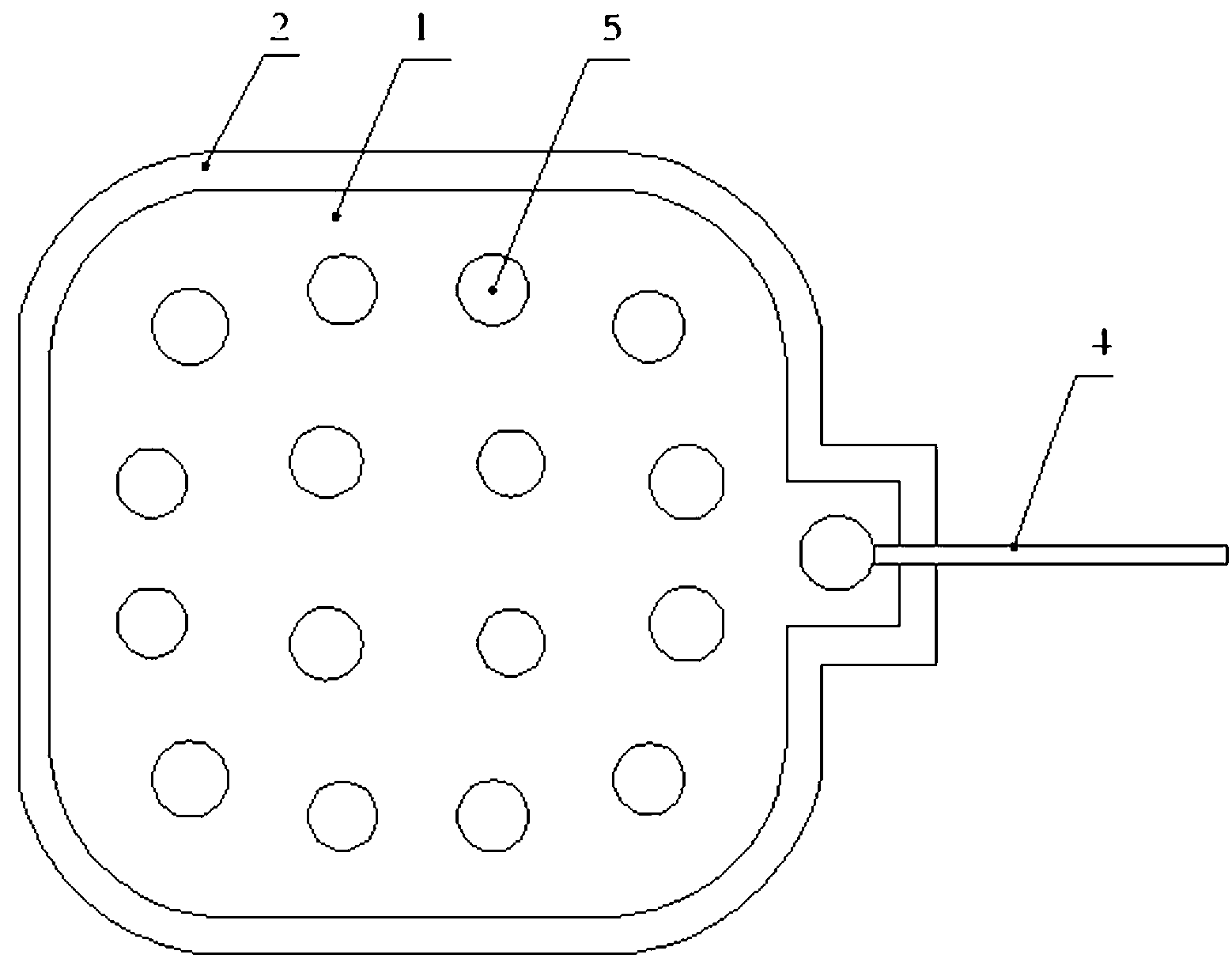

[0019] Such as figure 1 , 2 As shown, a kind of galvanic couple type corrosion sensor of the present invention comprises a body, and the body consists of

[0020] The metal electrode 3, the insulating sheet 2 and the carbon film electrode 1 are stacked together in sequence. The metal electrode 3 and the carbon film electrode 1 are electrically connected to the electrode lead-out wire 4, and a number of penetrating metal electrodes 3 and insulating sheets 2 are arranged on the body. And the through hole of the carbon film electrode 1. The carbon film electrode 1 is made of 99.9% high-purity graphite, which is an inert material and will not corrode in the environment. The electrode lead wire 4 is connected to the metal electrode 3 and the carbon film electrode 1 through conductive silver paste, and is sealed with an adhesive. In order to monitor more accurately, before assembly, the same coating as the coating on the metal material to be monitored is hot dipped, thermally spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com