Explosive detonation property testing system under pulse high voltage and tested explosive loading part

A testing system and technology for explosives, which are used in measuring devices, testing dielectric strength, and material analysis by electromagnetic means, can solve problems such as low accuracy, difficult testing, and inability to meet requirements, and achieve low cost and simple structure. , the effect of adjustable pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

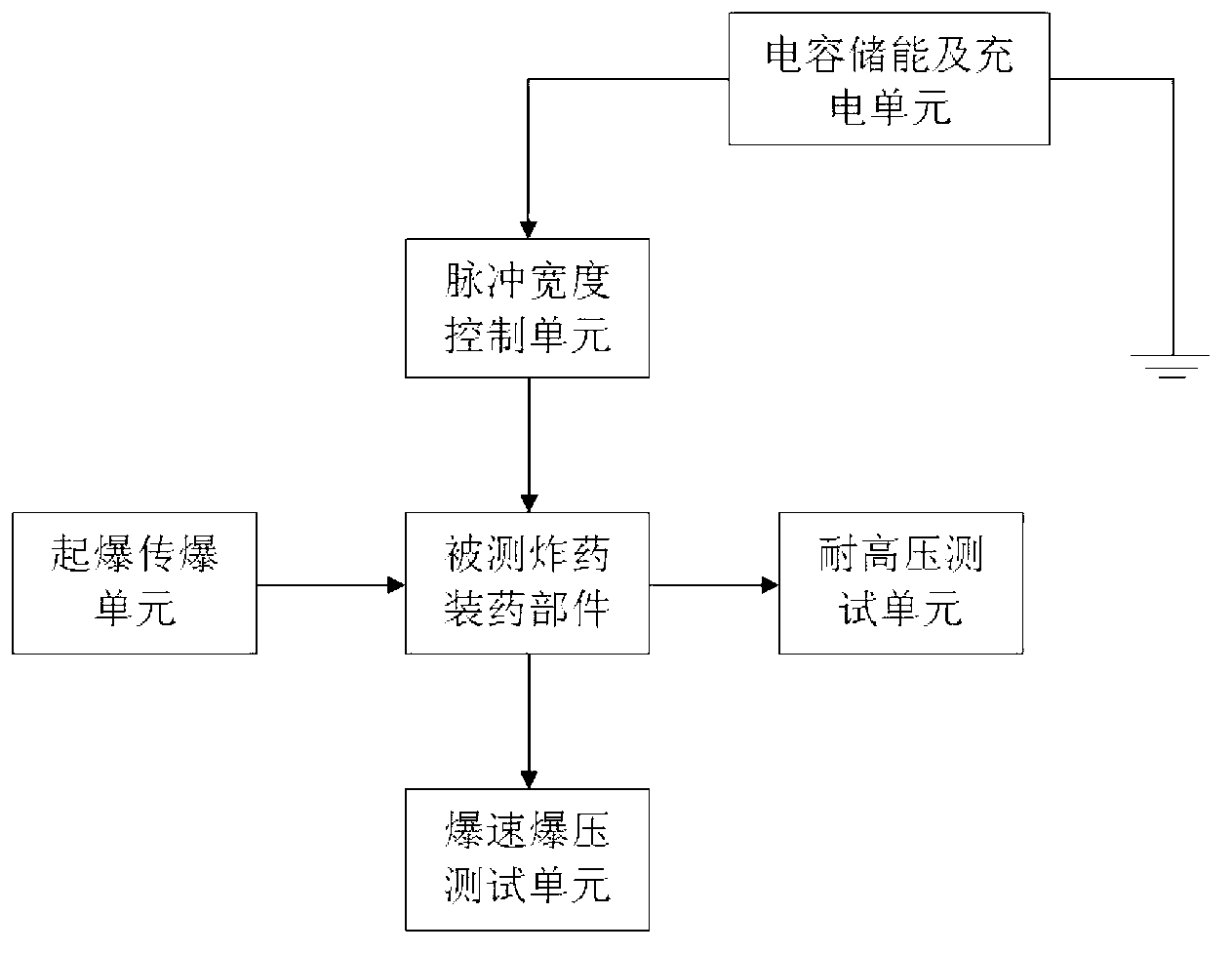

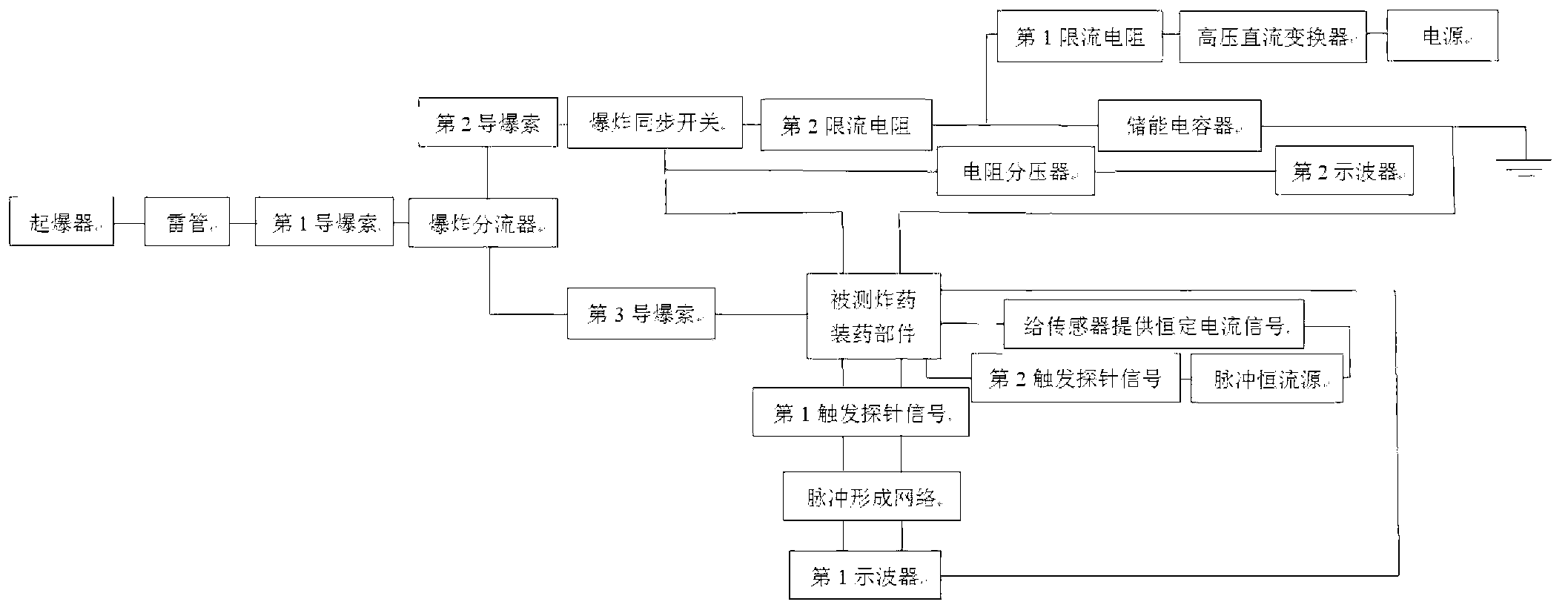

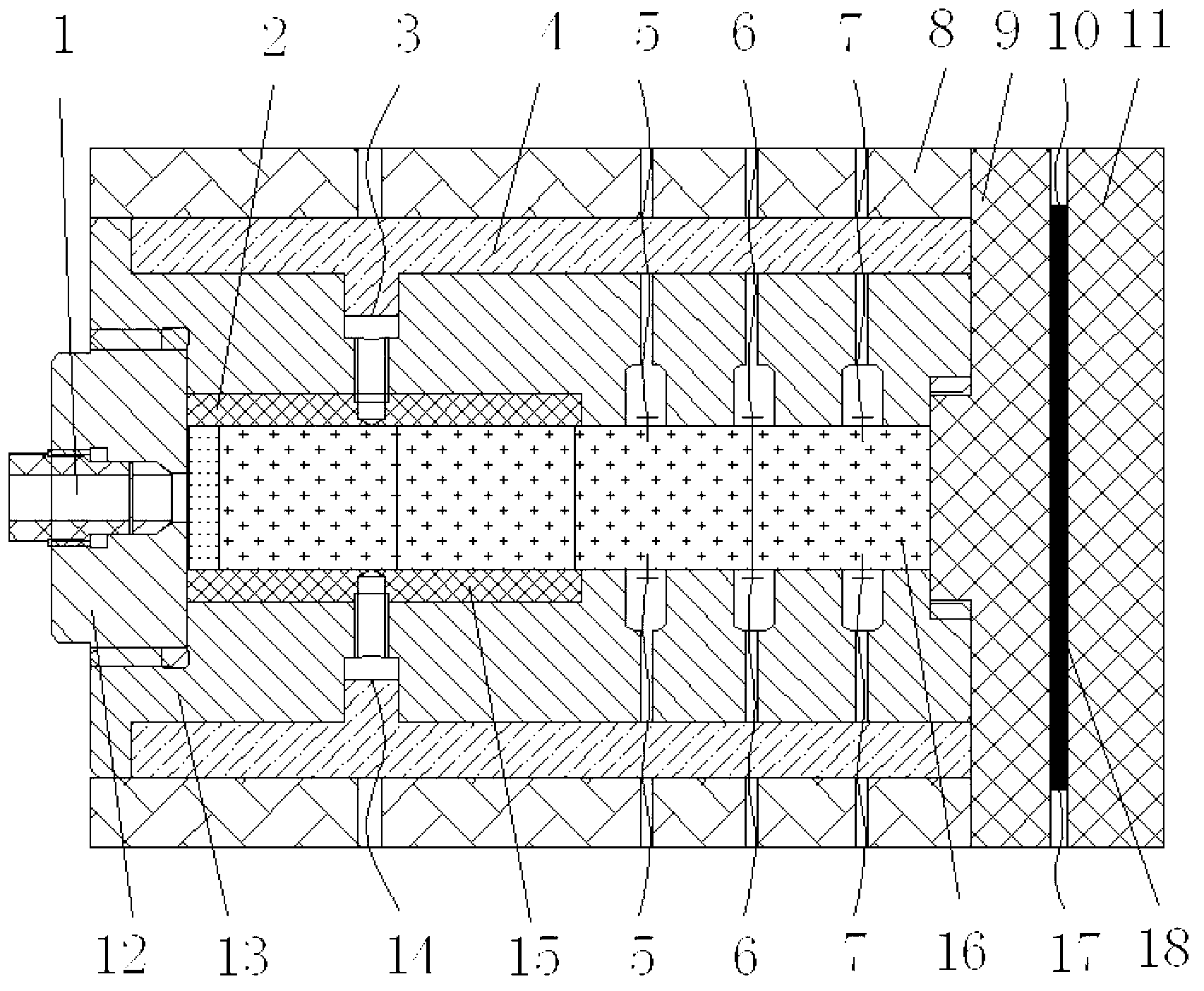

[0028] figure 2Shown is a block diagram of the embodiment of the present invention, including capacitor energy storage and charging unit, explosion synchronization switch, detonator, detonator, first detonating cord, explosion diverter, second detonating cord, third detonating cord by Measuring explosive charge components, pulse forming network, pulse constant current source and first oscilloscope; using power supply, high voltage DC converter, current limiting resistor, etc. to realize the charging control of energy storage capacitor; using detonator, detonator, detonating cord, Explosion shunt, explosion synchronous switch, etc. realize the detonation of the explosive under test and the high-voltage pulse width control loaded on the explosive component under test; use resistor divider, manganin piezoresistive sensor, pulse constant current source, trigger prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com