Dissoluble pressure building-up ball for conducting staged fracturing on shale gas well

A technology for staged fracturing and shale gas wells, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve problems such as flowback or grinding and milling pressure balls, and meet high pressure resistance and reliability Dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

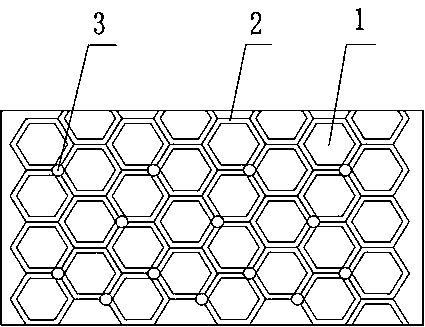

[0018] Such as figure 1 Shown is a dissolvable pressure-suppressing ball for staged fracturing of shale gas wells. The base material 1 for making the pressure-suppressing ball is metal Mg with a nucleus grain diameter of 60-100 μm, and the outer coating of the metal Mg grains is There is shell material 2 metal aluminum with a thickness of 10 μm, β-phase Fe is uniformly distributed in the gap of the metal aluminum, and the ratio of Mg, Al, and Fe is 5:3:2. In this embodiment, the above-mentioned material is used to make a pressure-suppressing ball with a diameter of 38.1mm for finite element analysis. The selected pure Mg material has an elastic modulus of 44.8GPa, a Poisson's ratio of 0.35, and an inner diameter of the ball seat of 35mm. The model analysis results show that when the sphere bears a pressure of 70MPa, the point of maximum stress is the contact point between the sphere and the surface of the ball seat, and the maximum stress value is 288MPa. The pressure-resisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com