Blind valve element of G-type electromagnetic directional valve and manufacturing method

An electromagnetic reversing valve and the technology of the manufacturing method are applied in the direction of sliding valves, valve devices, manufacturing tools, etc., which can solve the problems of low yield rate, metal corrosion-prone internal energy, low hardness and elastic modulus, etc., and achieve pressure resistance The effect of improving and reducing the difficulty of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

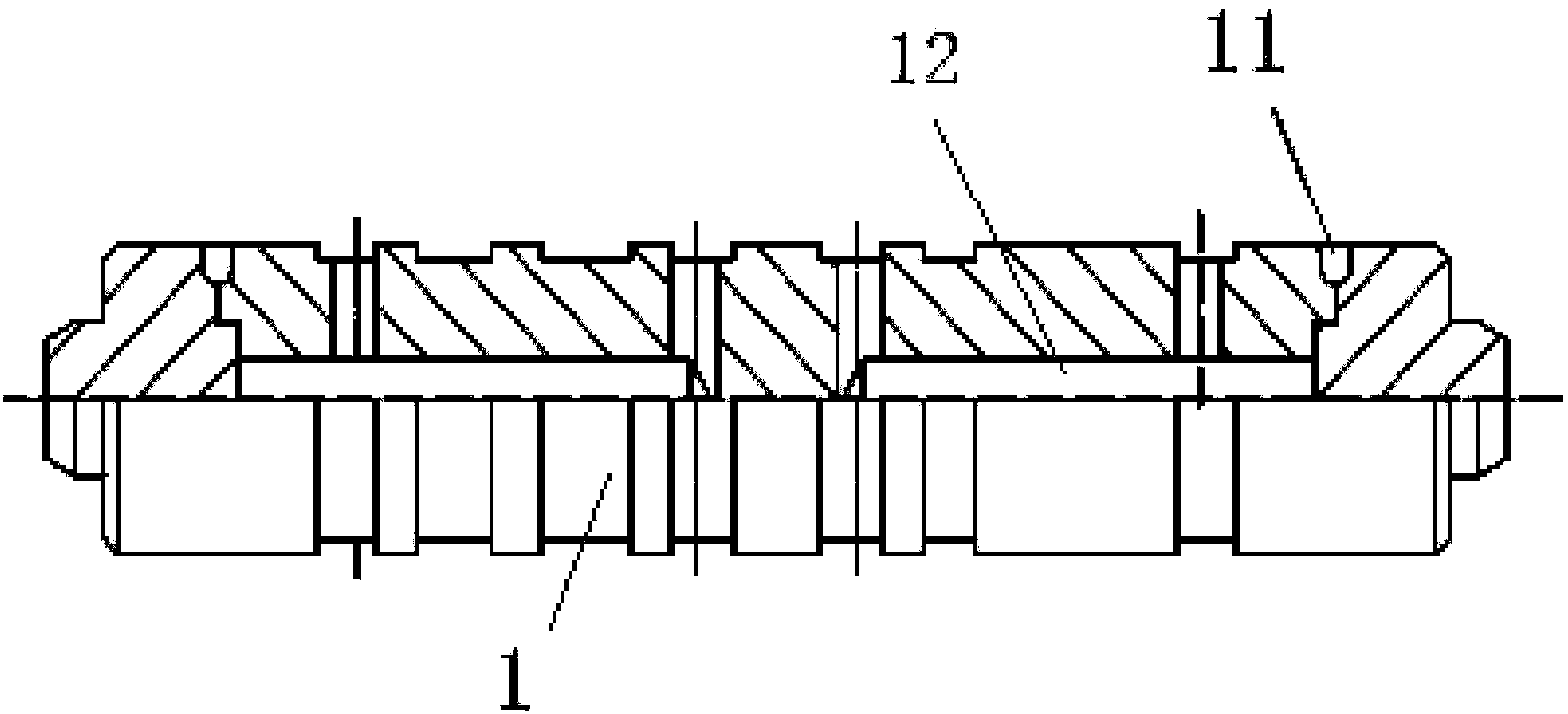

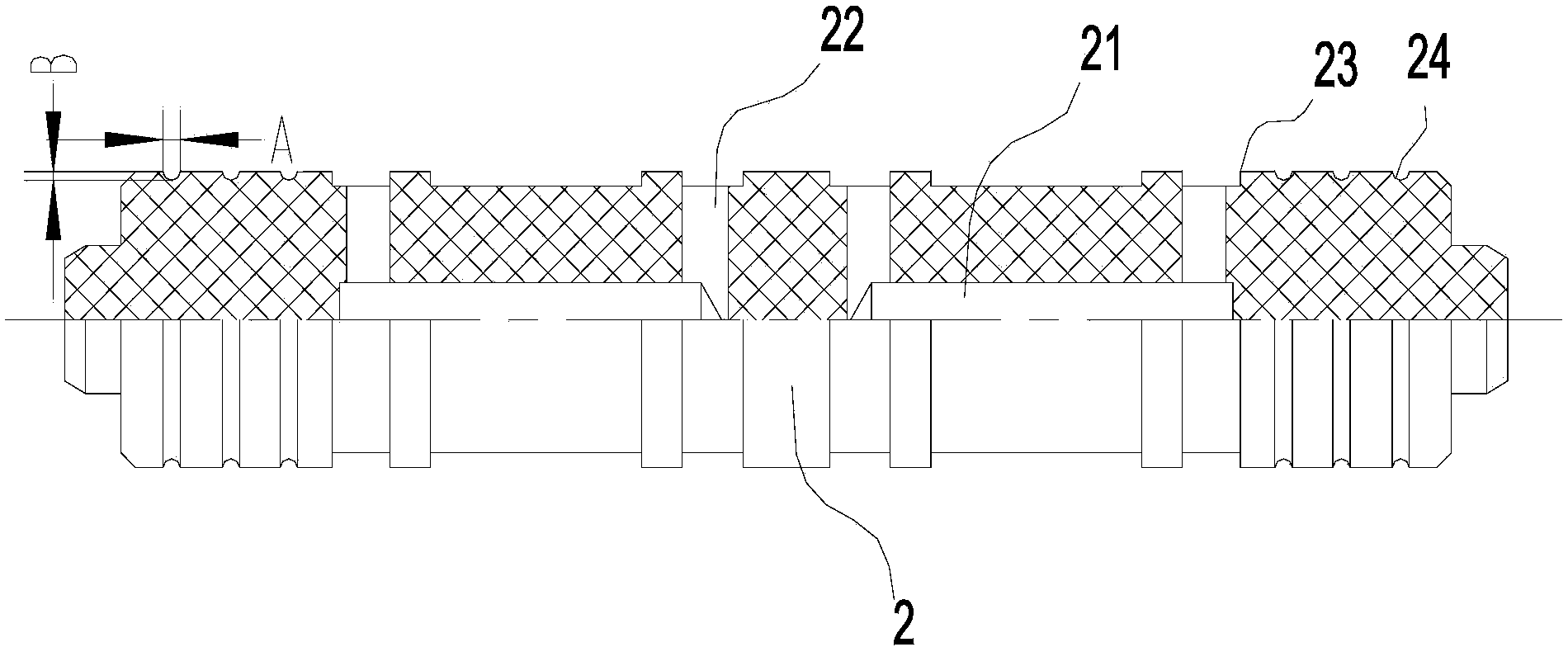

[0030] This embodiment provides a blind spool for G-type electromagnetic reversing valve, please refer to figure 2 , the blind spool 2 has an integral structure, and the blind hole 21 is processed through core bone making and core removal processes without welding.

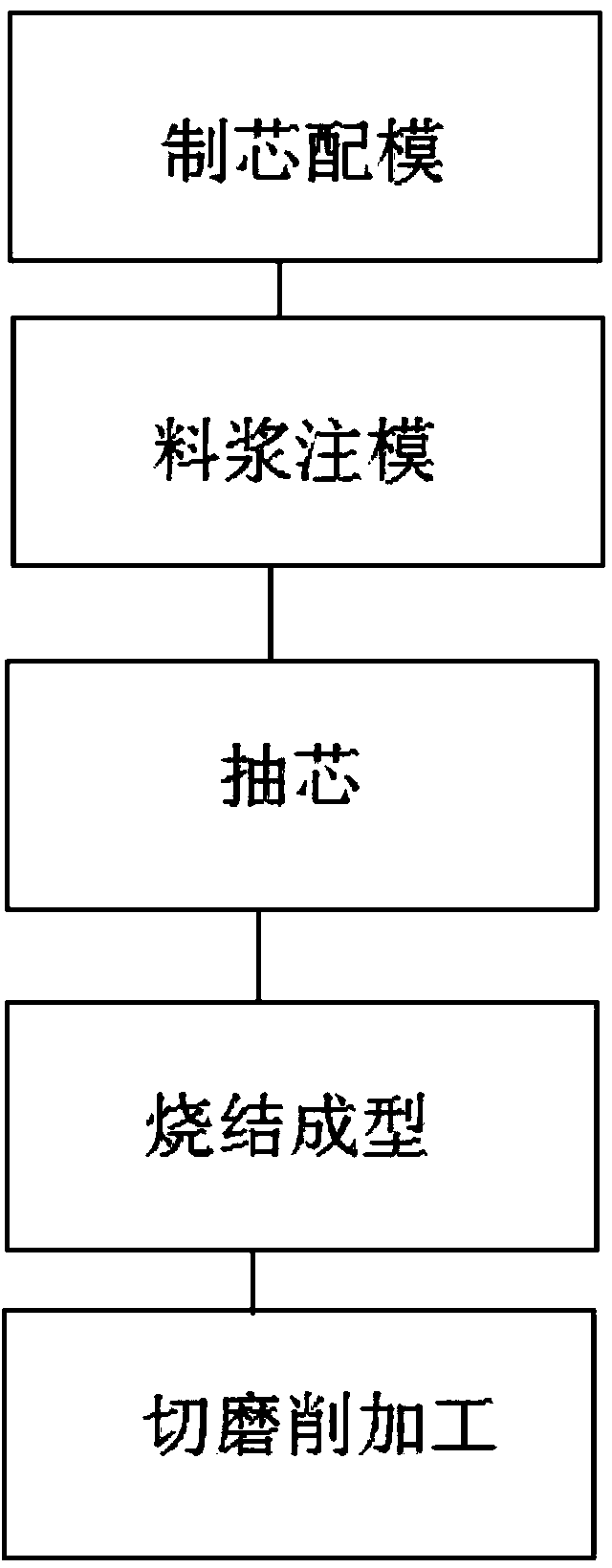

[0031] Specifically, please refer to image 3 , the manufacturing method of the blind spool comprises:

[0032] Core making and mold matching: set the mold, and the core bone is pre-embedded in the mold for the position of the blind hole;

[0033] Slurry injection molding: inject the slurry of special pottery raw materials into the cavity of the mold, and form the blind valve core blank;

[0034] Core pulling: remove the core bone in the blind valve core blank;

[0035] Sintering molding: sintering the blind valve core blank;

[0036] Cutting and grinding: Cutting and grinding the sintered blind valve core blank to make products.

[0037] Specifically, in the step of core making and mold matching, the mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com