Method and device for monitoring gas in transformer oil on line

A transformer oil and gas technology, applied in the field of substation status monitoring, can solve problems such as difficulty in obtaining detection results, ignoring the uncertainty of oil-gas separation, and poor stability, so as to reduce long-term poor stability, improve long-term stability, and improve detection The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific algorithms are provided, but the protection scope of the present invention is not limited to the following embodiments .

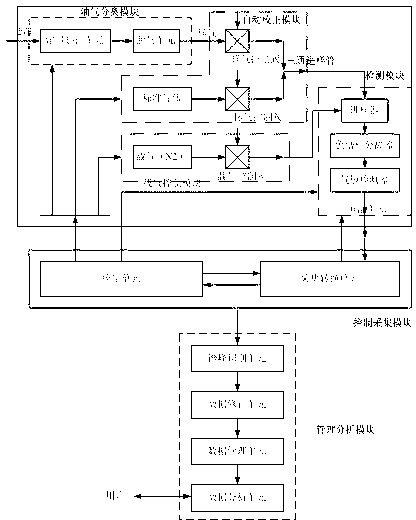

[0036] Such as figure 1 As shown, this embodiment includes:

[0037]A detection part, a control collection module and a management analysis module, the detection part includes an oil-gas separation module, a carrier gas control module, an automatic correction module and a detection module, the control collection module includes a control unit and a collection conversion unit, the management analysis module The module includes a data management unit, a data analysis unit, a data correction unit, and a spectrum peak identification unit. The oil-gas separation module receives the input of the transformer oil sample, and after passing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com