Method for measuring parameters of permanent magnet synchronous motor

A permanent magnet synchronous motor and parameter technology, applied in the direction of measuring electrical variables, measuring resistance/reactance/impedance, measuring devices, etc., can solve the problems of less current information obtained, affecting detection accuracy, and fewer sampling points, etc., to achieve the physical concept Clear, high-precision measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below with reference to the accompanying drawings.

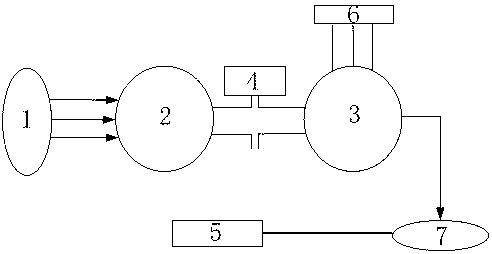

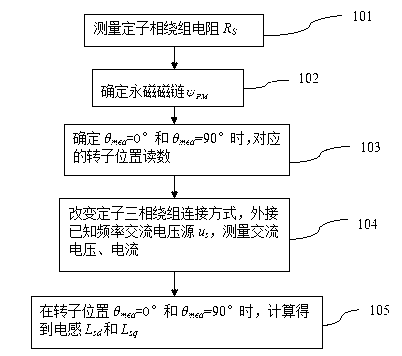

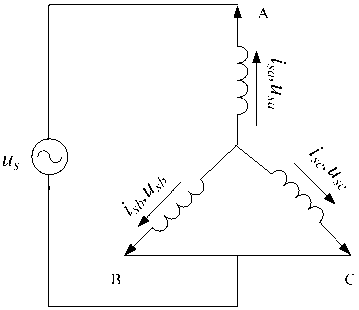

[0022] The device block diagram of the embodiment of the present invention is as figure 1 As shown, the measuring device includes: a three-phase asynchronous motor 2, a permanent magnet synchronous motor 3 and a DSP5, a coupling 4 is provided between the three-phase asynchronous motor 2 and the permanent magnet synchronous motor 3, and a permanent magnet synchronous motor 3 A position sensor 7 is provided between the DSP 5 ; the three-phase asynchronous motor 2 is connected with a three-phase voltage regulator 1 , and the stator three-phase winding 6 of the permanent magnet synchronous motor 3 is also included. The basic parameters of the three-phase asynchronous motor are: rated phase voltage U N =220V, rated phase current I N =11.8A, number of pole pairs p=2, rated speed n N =1500r / min; the basic parameters of permanent magnet synchronous motor are: rated phase voltage U N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com