Aero-engine reliability monitoring method based on mixed weibull distribution

An aero-engine and Weibull distribution technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of aero-engine performance degradation, inability to achieve precision, and inability to achieve real-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

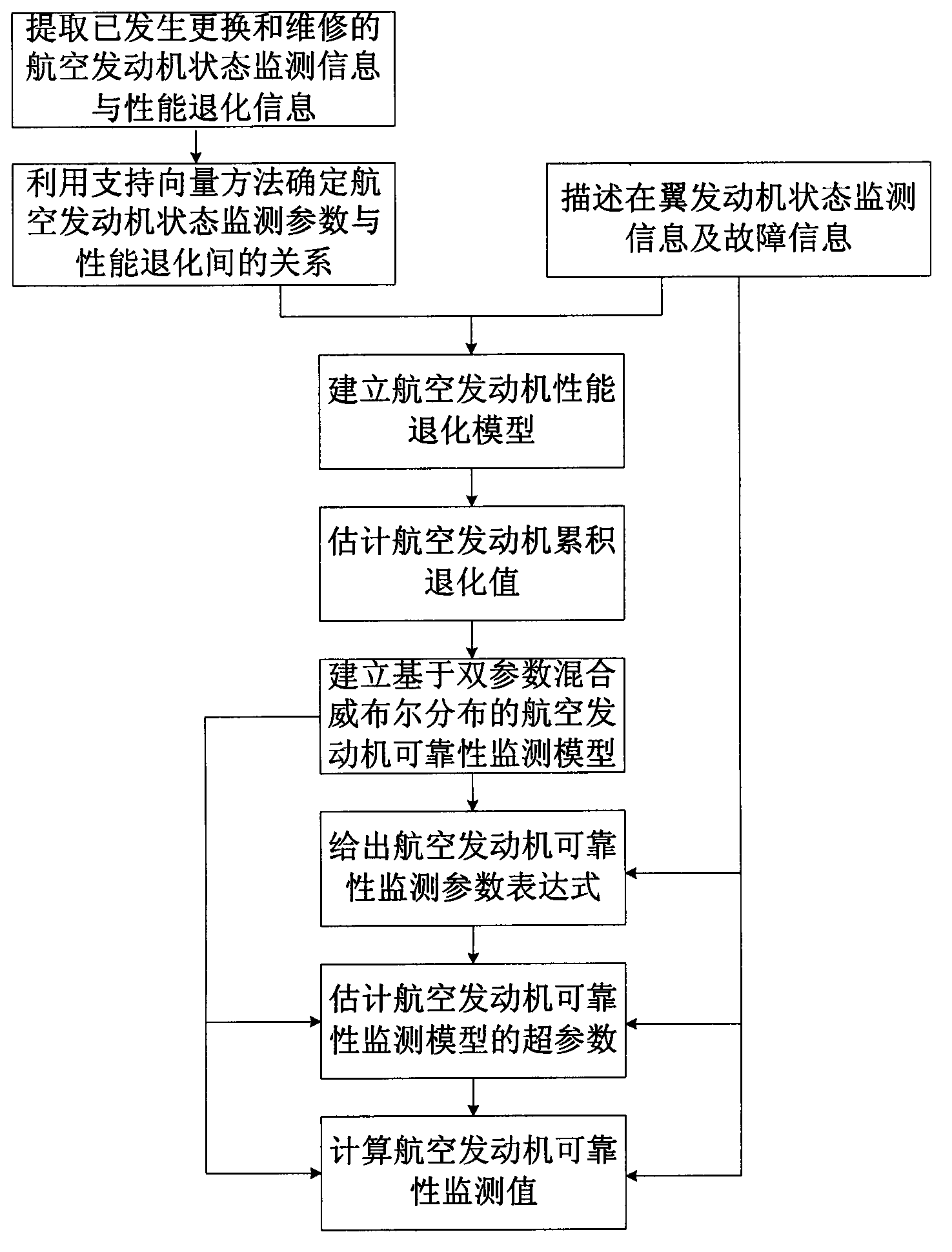

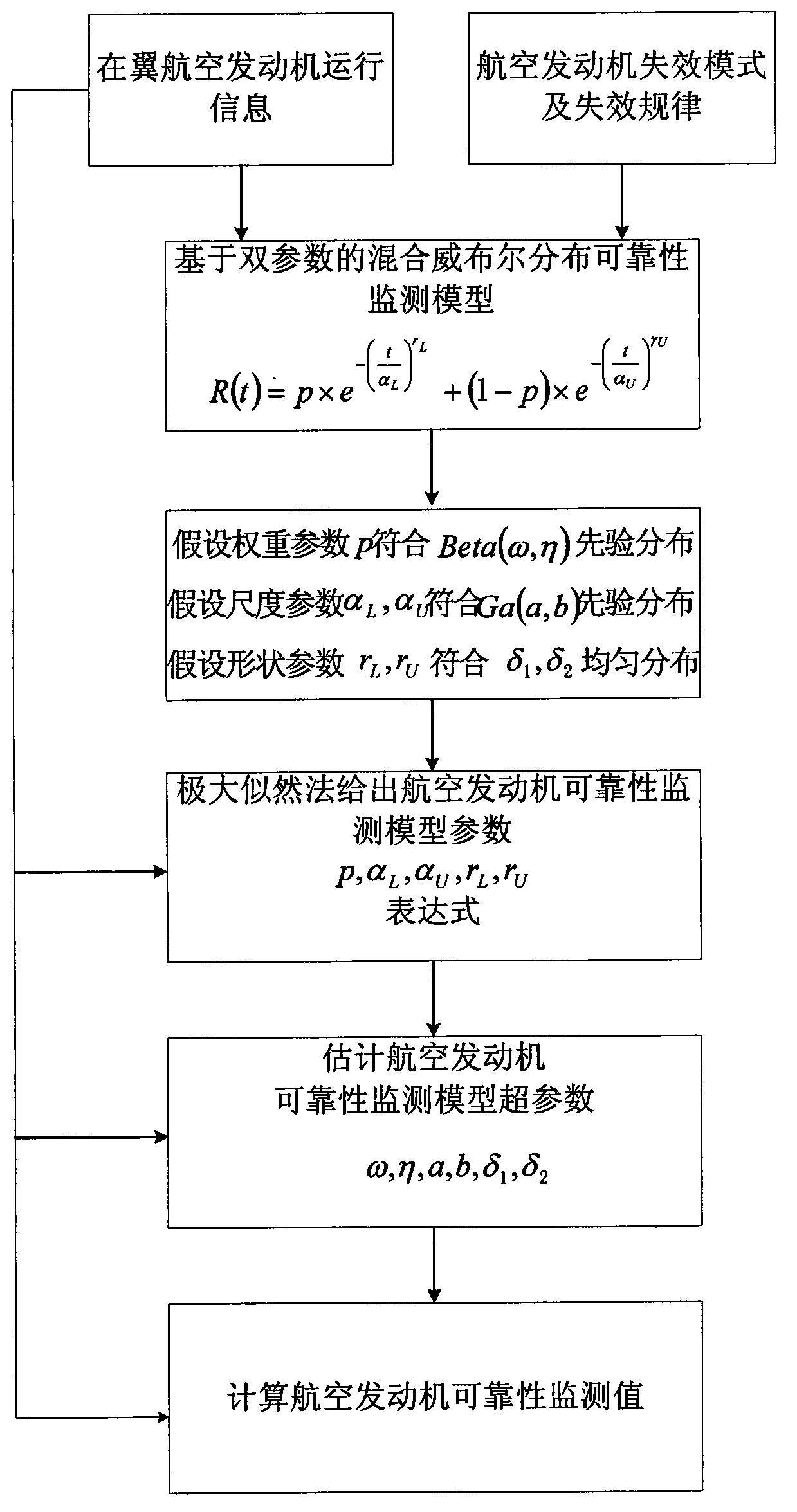

[0022] Aiming at the simultaneous existence of multiple failure modes and different failure laws of aero-engines, as well as the characteristics of a large amount of monitoring information and a small amount of fault information, an aero-engine reliability monitoring method is proposed. The implementation process can be divided into the following eight steps, as follows: figure 1 shown.

[0023] 1. Collect aero-engine condition monitoring information and performance degradation information

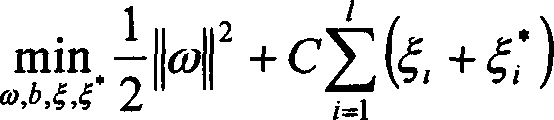

[0024] For aero-engines that have undergone inspection, replacement and maintenance, collect their condition monitoring information and corresponding performance degradation information. The performance degradation monitoring indicators of the present invention are selected from the indicators of gas path performance monitoring, lubricating oil monitoring and vibration monitoring, involving the following 6 monitoring indicators: engine exhaust temperature deviation (DEGT), fuel consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com